PVC pipe cutter

A pipe and blade technology, applied in the field of labor-saving PVC pipe cutter, can solve the problems of insufficient cutting and labor saving, and achieve the effect of light and labor-saving operation, fast and light cutting of pipes, and reducing the feeling of extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

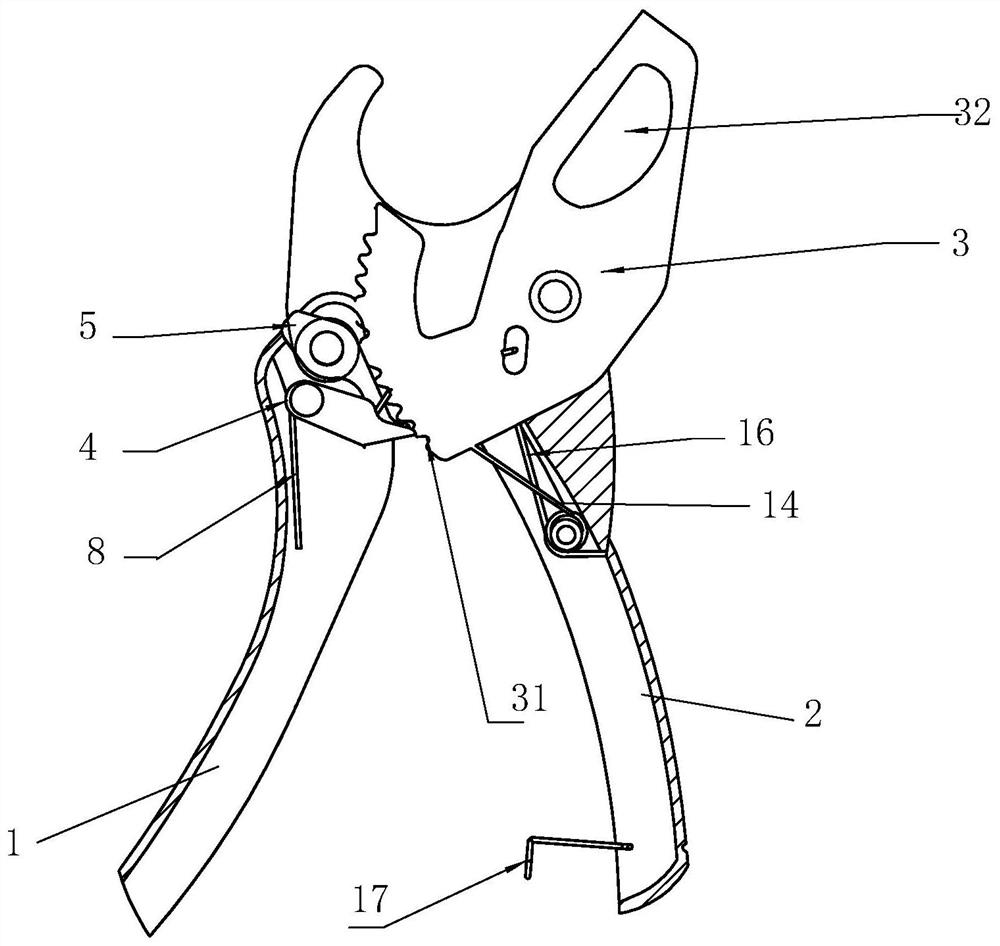

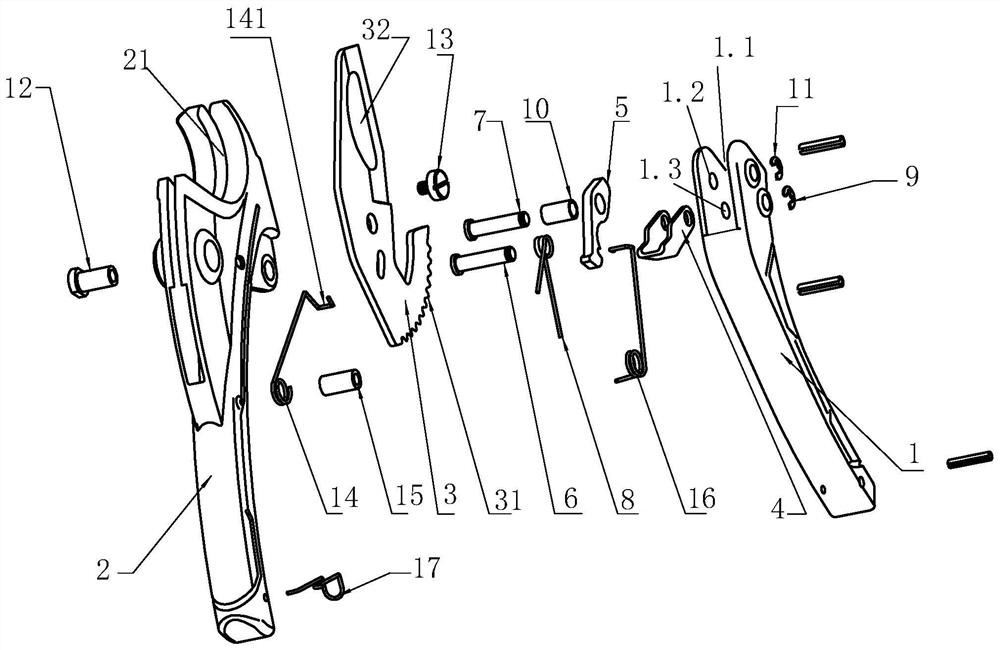

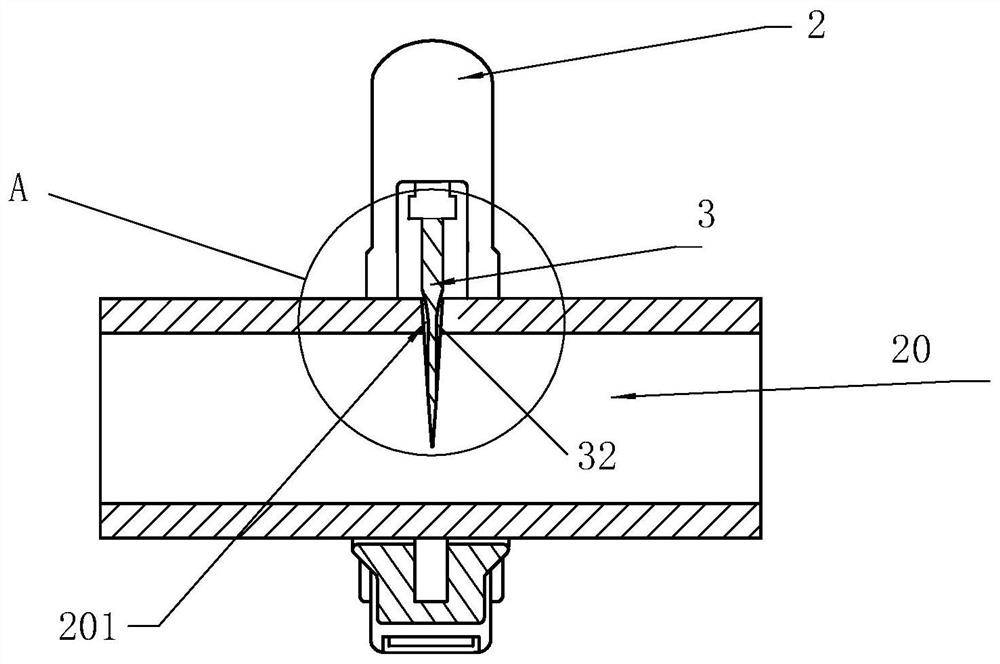

[0021] Such as Figure 1~4 As shown, a labor-saving PVC pipe cutter includes a left handle 2 and a right handle 1 hinged to each other. The upper end of the left handle 2 is provided with a blade groove 21 for inserting the blade 3. The blade 3 is C-shaped. The blade 3 It is arranged in the blade groove 21 and fixed by the screw 12 and the nut 13. The blade 3 is a toothed blade with serrations 31 on the lower end surface. Shaped concave surface, the bottom edge adjacent to the knife edge is a straight edge, the top edge away from the knife edge is arched, and the sides on both sides have arc transitions, forming a similar D-shaped profile. The wall thickness of the blade 3 at the concave surface 32 is controlled within an appropriate range Inside, the maximum size of the concave surface 32 is usually that its base is greater than the outer di...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap