Sealed screening machine

A technology of screening machine and sealing ring, applied in the direction of filter screen, solid separation, grille, etc., can solve the problem that the screening machine cannot achieve continuous feeding and closed screening, reduce large-area contact, prevent dust flashing, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

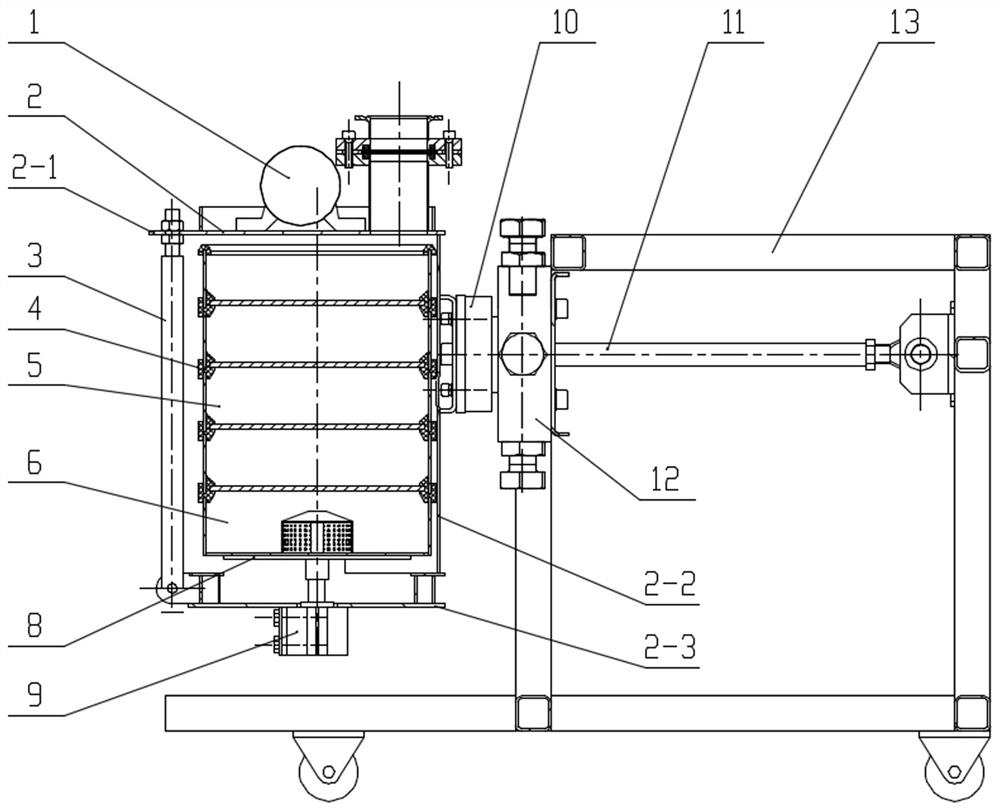

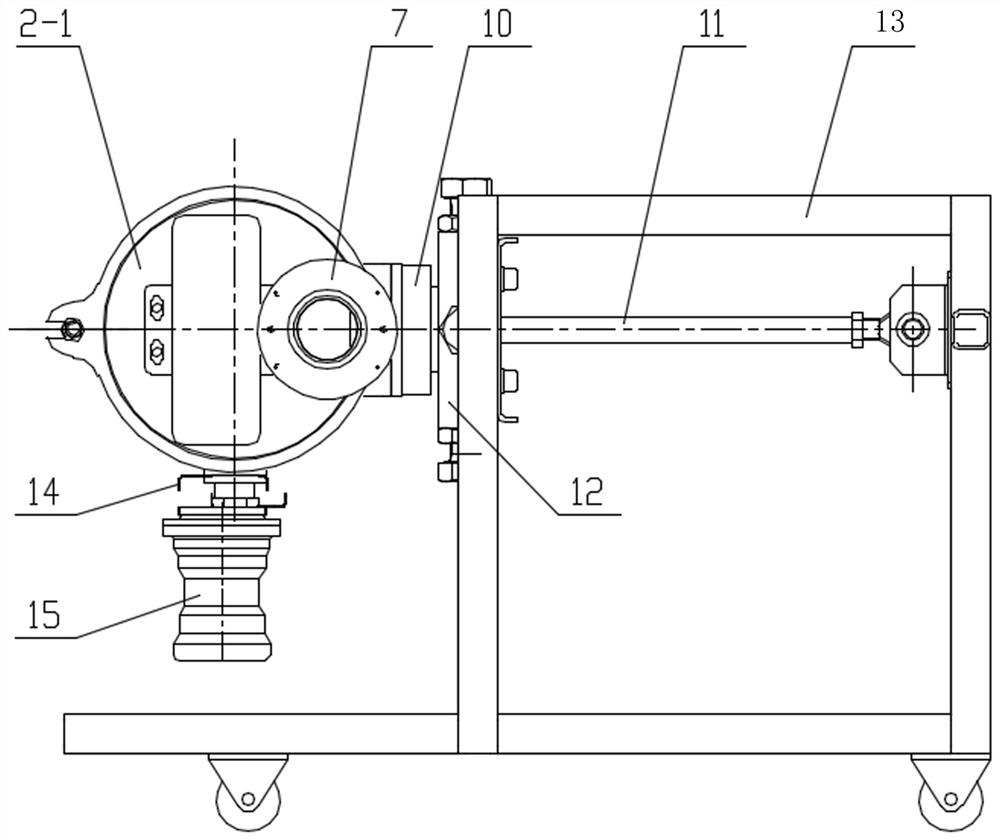

[0030] Such as Figure 1-2 As shown, a sealed screening machine, the vibrating screen main body of the screening machine is installed on the suspension support frame body, the vibrating screen main body includes a vibrating motor 1, a screen frame 2, a locking device, a special sieve tray 5, and a sieve tray seat 6, The sieve frame 2 is fixed on the suspension support frame body, the upper plate 2-1 of the sieve frame 2 is provided with a sample loading interface 7, and the sieve frame 2 is provided with a vibrating motor 1, and the present invention does not limit the specific setting position of the vibrating motor 1 In this example, the vibrating motor 1 is arranged on the top of the screen frame 2, and can also be arranged at any position such as the bottom of the screen frame 2, the side, etc., and its purpose is to provide a source of vibration for the main body of the vibrating screen. The sieve frame 2 is provided with a plurality of special sieve trays 5 which are sna...

Embodiment 2

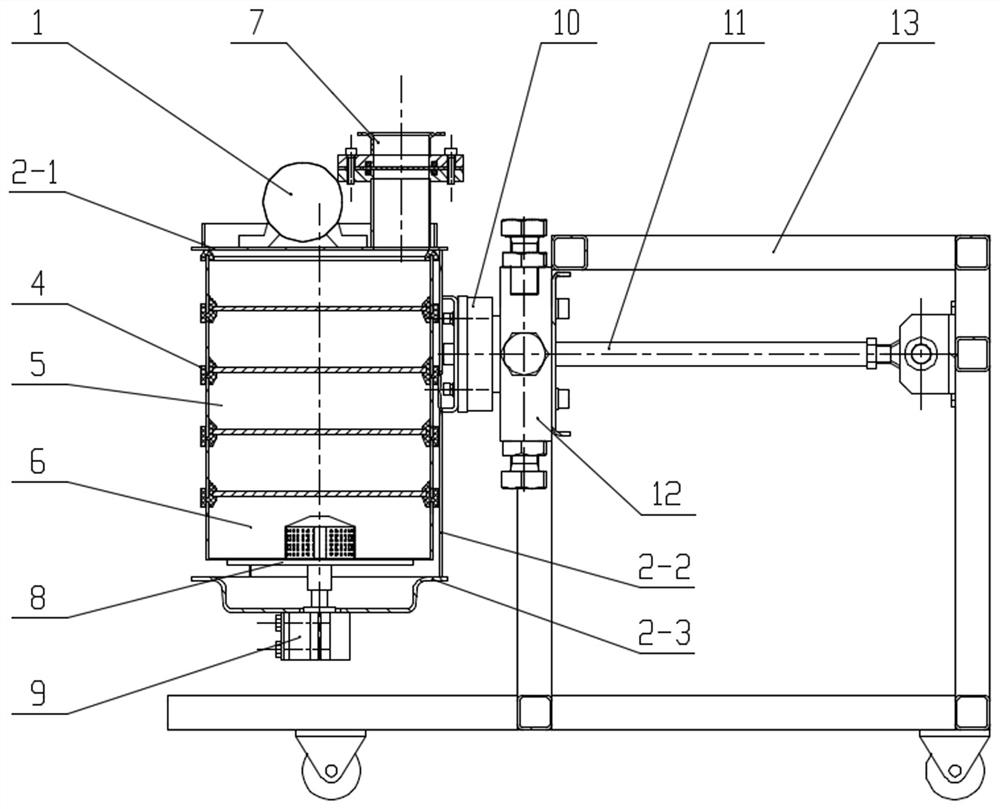

[0045] The overall structure is substantially the same as that of Embodiment 1, except that the front column is canceled by changing the surrounding angle of the side plate 2-2, which makes it easier to take and place the special sieve tray 5 and the sieve tray seat 6, such as image 3 shown.

[0046] Instructions:

[0047] Unlock the locking cylinder 9, directly fit the sieve tray seat 6 and multiple special sieve trays 5 from bottom to top and place the special sealing ring 4 and the top sealing ring 5-3, open the locking cylinder 9, and pass the locking cylinder 9 piston rod Push the sieve tray seat 6 and multiple special sieve trays 5 together with the top sealing ring 4 and the top top sealing ring 5-3 to move up and press the upper plate 2-1 at the same time to realize the sieve tray seat 6 and multiple special sieve trays 5 The fixing and sealing between them ensure the overall stability of the main body of the vibrating screen. Through the movement of the vibrating m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap