Stainless steel well lid pattern finish machining device and implementation method thereof

A stainless steel and manhole cover technology, applied in artificial islands, decorative arts, water conservancy projects, etc., can solve the problems of increasing the difficulty of finishing, and achieve the effect of reducing the difficulty and making the structure complete and reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

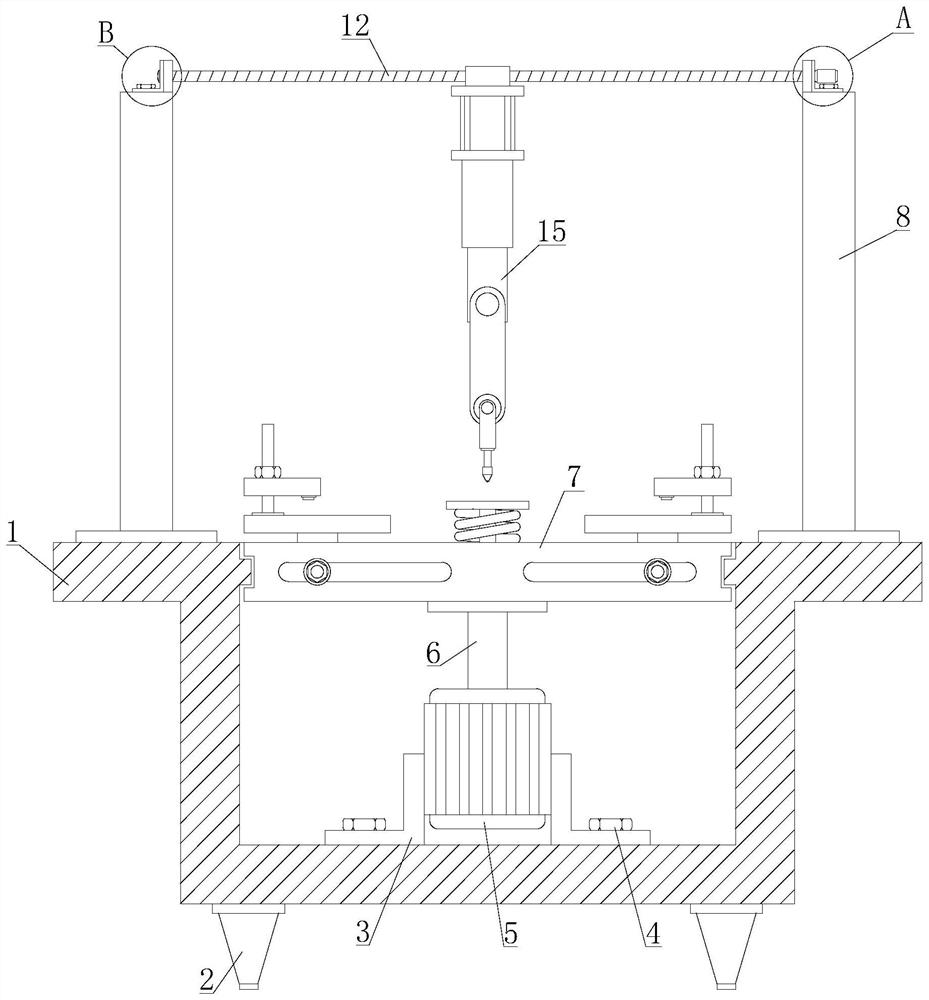

[0030] In order to better demonstrate the implementation process of the stainless steel manhole cover pattern finishing device, this embodiment now proposes an implementation method of the stainless steel manhole cover pattern finishing device, including the following steps:

[0031] Step 1: Measure the size of the stainless steel manhole cover to get rid of the size of the manhole cover, adjust the distance between the bottom splints 75 at both ends of the turntable fixture 7, and install the positioning lock bolts in the embedded slider 74 to complete the fixation;

[0032] Step 2: Place the stainless steel manhole cover on the bottom splint 75, press down the support head 710 and the support spring 711, and tighten the pressure bolt 78 downward to lower the movable splint 77, and press the stainless steel manhole cover through the manhole cover chuck 79 ;

[0033] Step 3: Select a suitable finishing installation head 1511 according to the type of manhole cover finishing, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com