Double-motor single-speed hub speed reduction parallel-axis electric drive axle

A wheel-side reducer and parallel shaft technology, which is applied in the directions of axles, wheels, electric power devices, etc., can solve the problems of difficult to balance the power and economy of the whole vehicle, the layout space of the large chassis structure, and the narrow efficient working area of the motor. , to achieve the effect of flexible layout of axles, saving chassis space and improving vehicle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

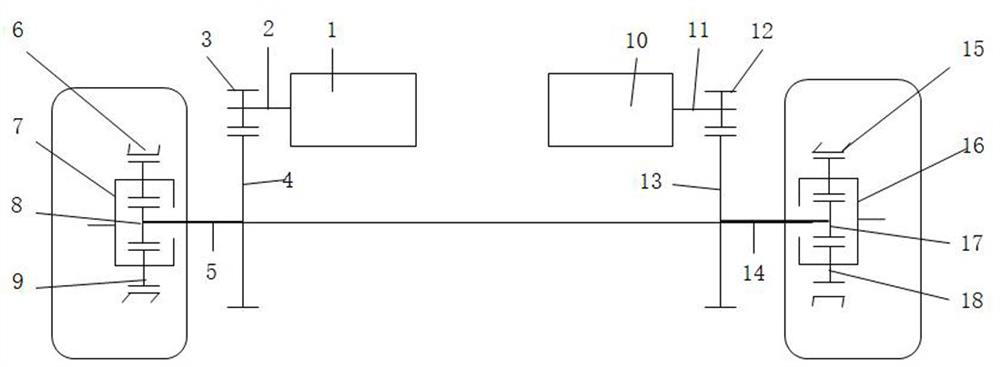

[0018] Such as figure 1 As shown, the present invention is a dual-motor single-speed pulley-side deceleration parallel-axis electric drive axle, including a first motor 1, a second motor 2, a first output half shaft 5, a second output half shaft 14, The first wheel reducer assembly, the second wheel reducer assembly, the first reducer assembly and the second reducer assembly. Wherein, the first motor 1 is installed on the first reducer assembly, and the second motor 2 is installed on the second reducer assembly. The two ends of the first output semi-shaft 5 are respectively connected with the first wheel side reducer assembly and the first reduction gear 4, and the two ends of the second output semi-shaft 14 are connected with the second wheel side reducer assembly and the second reduction gear respectively. Gear 13 is connected. The first motor 1 and the second motor 10 are drive motors of the same type, and the first motor 1 and the second motor 10 are arranged coaxially a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com