Kraft paper packaging machine

A packaging machine and paper bag technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of difficult packaging quality assurance and low work efficiency, and achieve the effect of improving work efficiency and packaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

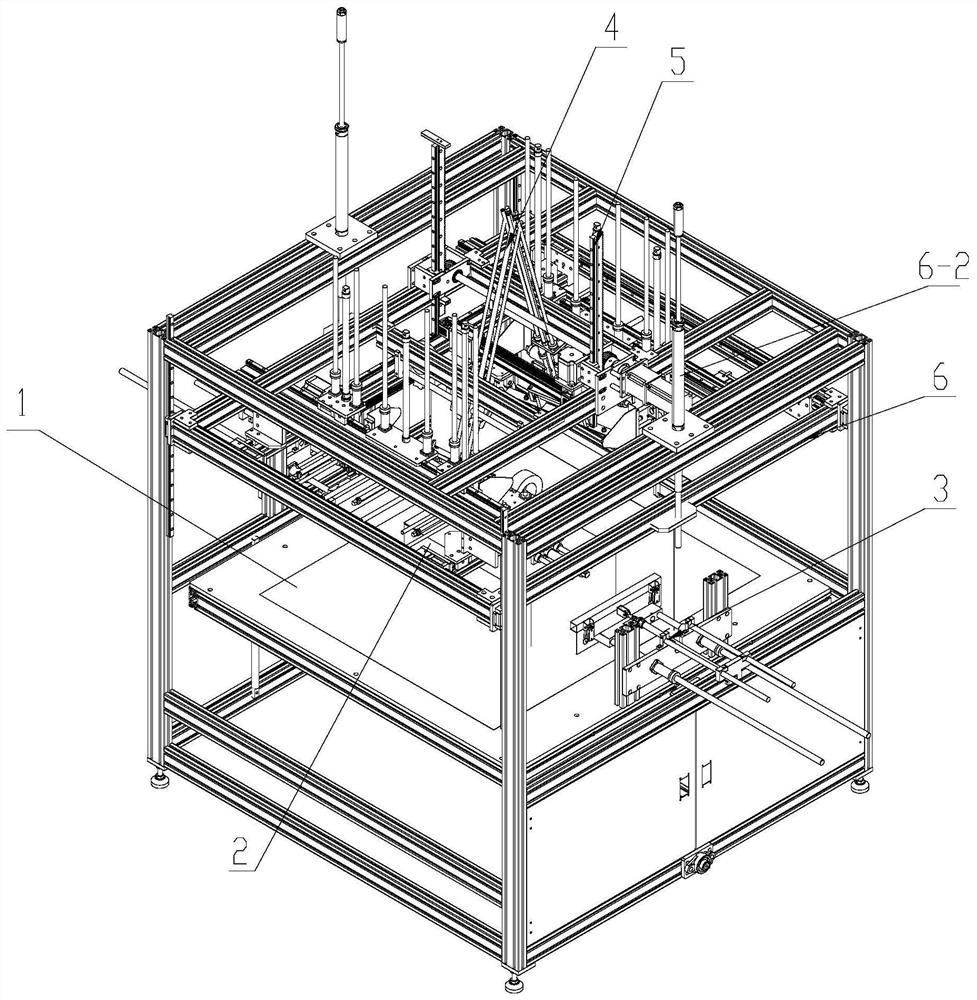

[0028] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0029] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

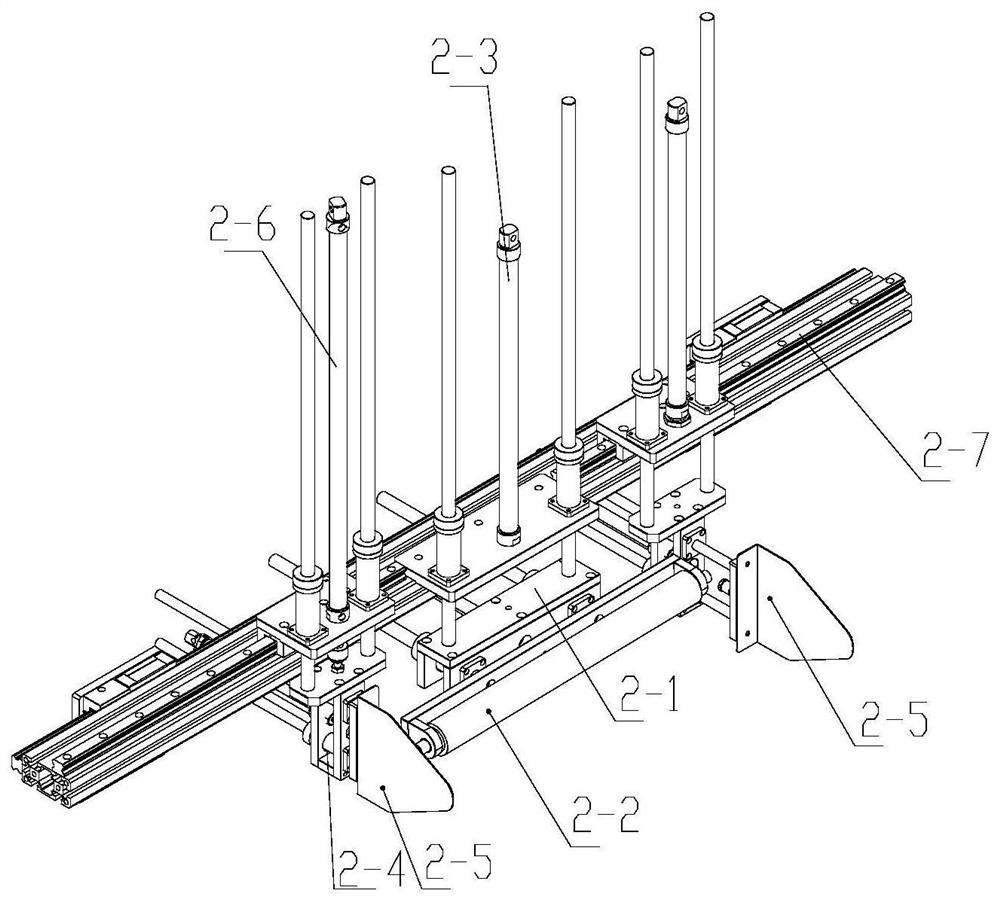

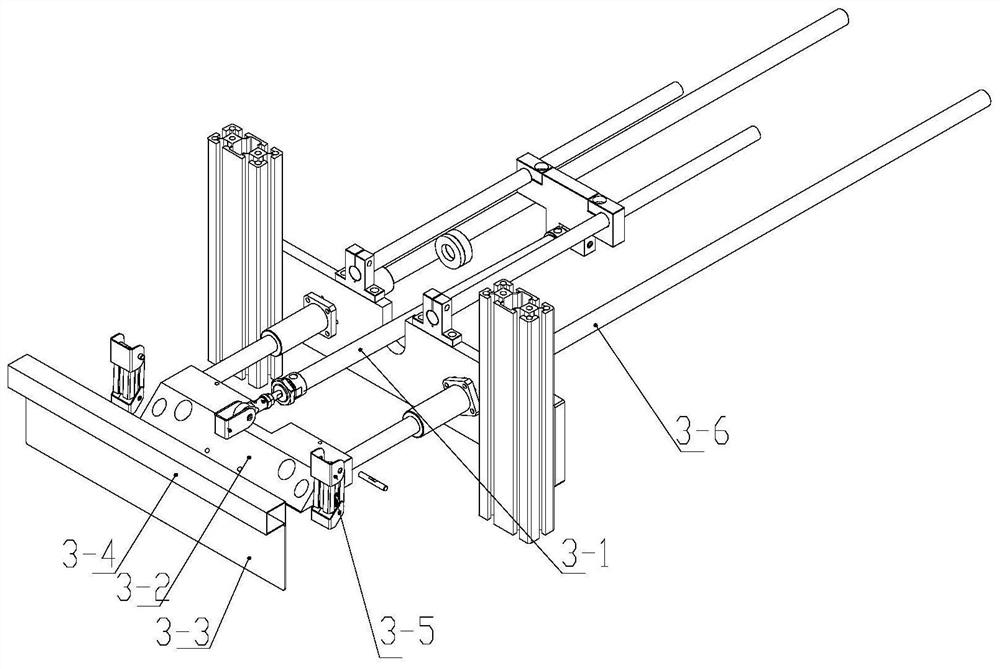

[0030] The present invention is realized in this way, a kind of kraft paper packaging machine, comprises lifting platen 1, and lifting platen 1 is driven by lifting sprocket component (using sprocket to drive lifting is a common technical means in this field, do not go into details here), in The front and rear sides of the lifting platform 1 are respectively provided with pushing side parts 2, and the left and right sides of the lifting platform 1 are respectively provided with folding side parts 3, and the upper and lower sides of the lifting platform 1 are provided with a liftable paper absorbing part 4 and a sticker. Tape parts; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com