Buried garbage can capable of automatically cleaning accumulated snow

A buried, trash can technology, used in trash cans, garbage collection, garbage cleaning, etc., can solve the problems of falling off balance, easy to step on, unable to see the trash can, etc., to improve the snowproof performance, easy to use, Improve the effect of garbage storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

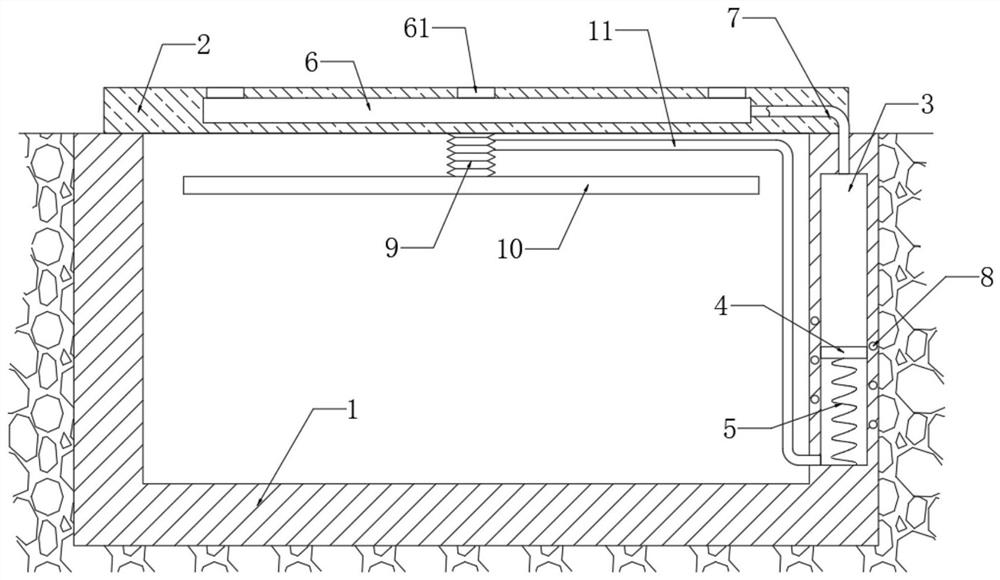

[0024] refer to figure 1 , a kind of self-cleaning snow-covered underground trash can, comprising a bucket body 1 buried underground on the road surface, a bucket cover 2 is installed on the bucket body 1, a chute 3 is opened on the side wall of the bucket body 1, and the chute 3 The inner seal is slidingly connected with a magnetic sliding plug 4, and the sliding plug 4 and the lid spring 5 are elastically connected to the inner bottom of the chute 3, and the side wall of the bung 2 is provided with an air guide groove 6, and the inner top of the air guide groove 6 A plurality of air outlets 61 are provided, and the air guide groove 6 communicates with the chute 3 through a conduit 7 . The inner wall of the chute 3 is embedded with a helical coil 8 , and a heating wire coupled with the helical coil 8 is installed in the conduit 7 .

[0025] The lower end of the barrel cover 2 is fixedly connected with a bellows 9, and the lower end of the bellows 9 is fixedly connected with a...

Embodiment 2

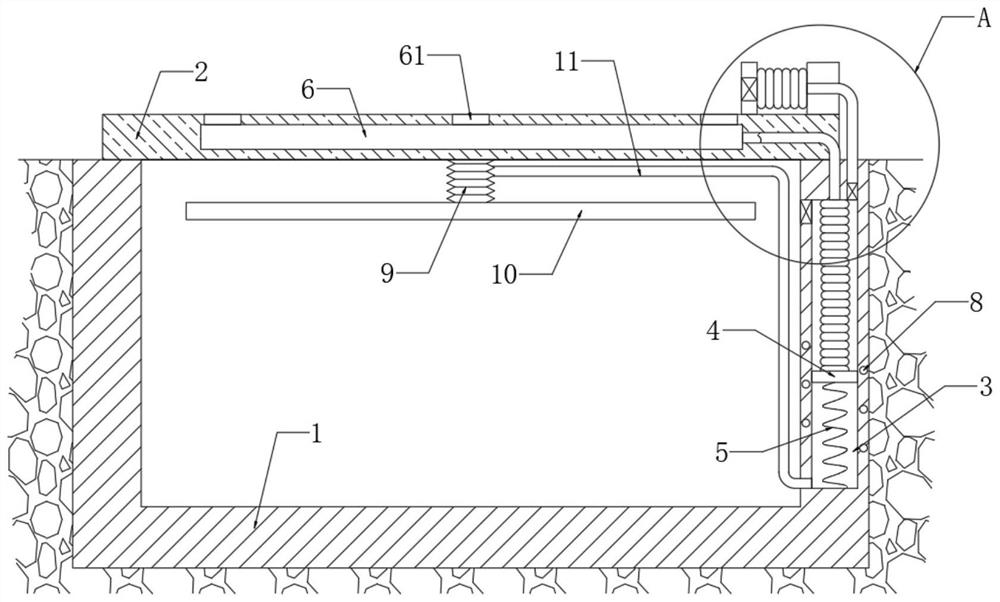

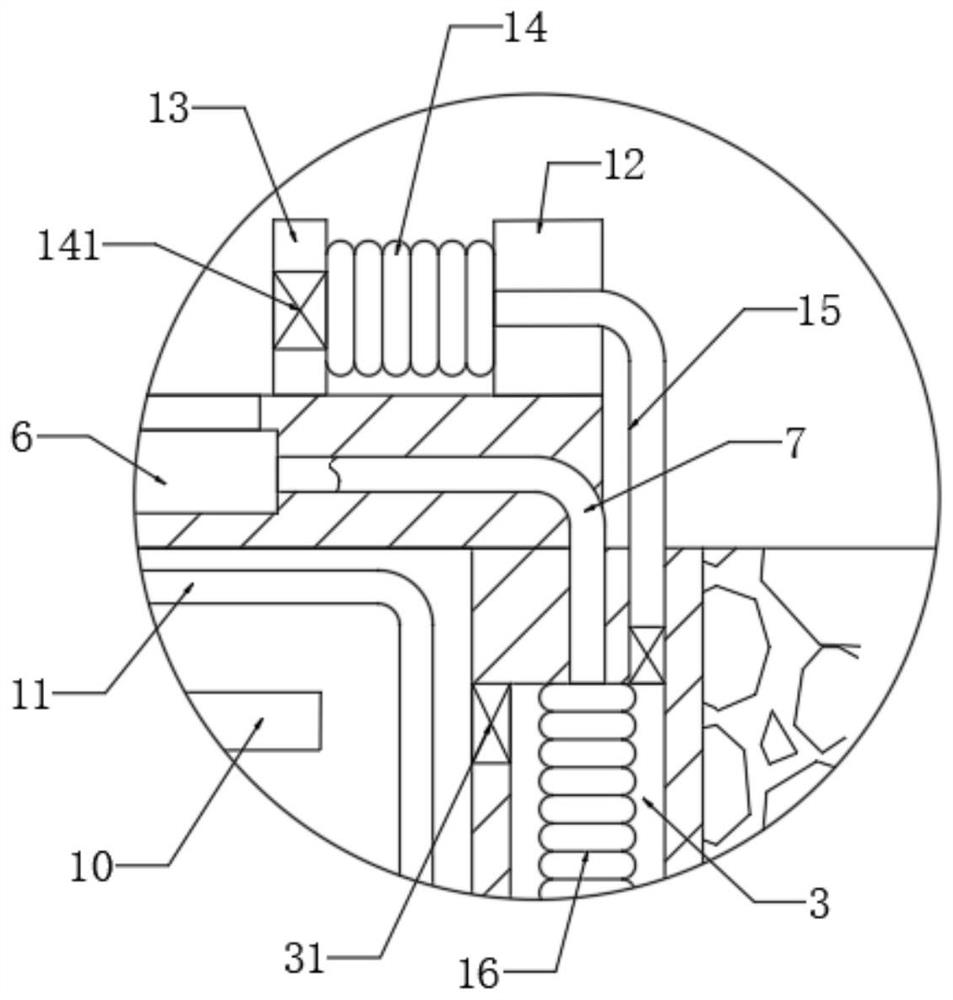

[0029] refer to Figure 2-4 , different from Embodiment 1, the upper end of the bucket lid 2 is fixedly connected to the limit plate 12, the side wall of the limit plate 12 is fixedly connected to the first telescopic airbag 14, and the end of the first telescopic airbag 14 away from the limit plate 12 is fixed A scraper 13 is connected, a pressure relief valve 141 is installed in the air outlet of the first telescopic airbag 14 , and an air supply device for supplying air to the first telescopic airbag 14 is installed in the chute 3 . The threshold value of the pressure relief valve 141 is set to the air pressure value in the first telescopic air bag 14 when the scraper 13 moves from one side of the bucket cover to the other side.

[0030] The air supply device includes a one-way air outlet pipe 15 fixedly connected to the top of the chute 3, and the one-way air outlet pipe 15 communicates with the first telescopic air bag 14. The inner wall of the chute 3 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com