Pneumatic oil injection device and control method thereof

The technology of an oil injection device and a control method, which is applied in the direction of distribution device, engine components, engine lubrication, etc., can solve problems such as the inability to flexibly adjust the amount of grease, shaft seal failure due to lack of oil, and single oil supply lubrication mode, etc., to achieve Variety of lubrication modes, low manufacturing cost and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

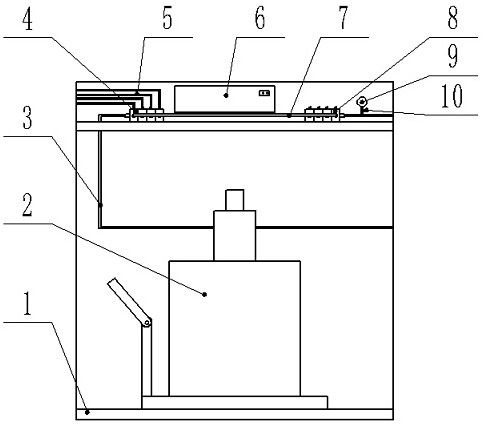

[0052] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Figure 8As shown, a pneumatic oiling device includes an oiling machine 2, an oil separator 4, a control valve group 8 and a controller 6, the oiling machine 2 is a pneumatic oiling machine, the controller 6 is a PLC controller, and the controller 6 is provided with Two-color indicator light.

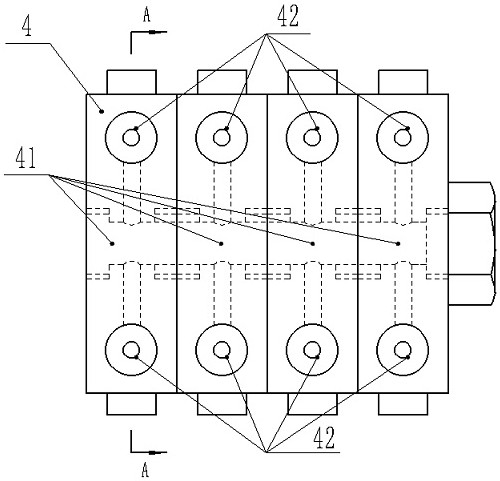

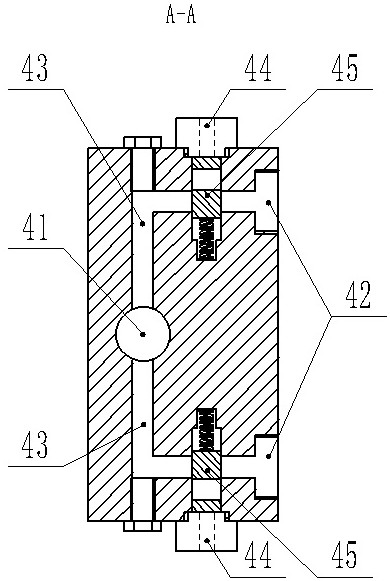

[0053] The oil separator 4 is connected in parallel with four reversing valves 40. The number of reversing valves 40 can be increased or decreased according to the number of lubricating points of the equipment used. It is economical and practical. Each reversing valve 40 is equipped with two first Spool port 44 and two first oil outlets 42, each first spool port 44 corresponds to one first oil outlet 42, and the first oil outlets 42 are respectively connected to the oil supply branch pipe 5, the oil supply branch pipe 5 is Composed of multiple lubricating oil pipes, the number of oil supply branch pipes 5 ...

Embodiment 2

[0066] The difference from Embodiment 1 is that the control method of the pneumatic oil injection device includes a sequential oil supply lubrication control method and a simultaneous oil supply lubrication control method.

[0067] Sequential oil supply lubrication control method: compressed air enters the oil injection machine 2 through the air pipe, the controller 6 controls the operation of the oil injection machine 2 through the program, and the oil injection machine 2 pumps the lubricating grease to the reversing valve in the oil separator 4 through the oil supply main pipe 3 The first main oil circuit 41 of 40, the lubricating grease enters the first oil distribution circuit 43 from the first main oil circuit 41, and the high-pressure air or the hydraulic oil pumped by the external hydraulic station enters the electromagnetic control valve group 8 through the external pipeline. The main circuit 81 of the valve 80, high-pressure air or hydraulic oil enters the branch circu...

Embodiment 3

[0070] Such as Image 6 with Figure 7 As shown, the difference from Embodiment 1 is that the oil separator 4 is a whole, and the oil separator 4 is provided with eight second oil outlets 47 and eight second spool ports 49, and each second spool port 49 Corresponding to one second oil outlet 47, the second oil outlet 47 is connected to the oil supply branch pipe 5 respectively, and the inside of the oil distributor 4 is provided with one second main oil circuit 46 and eight second oil distribution channels 48, the second oil distribution The roads 48 communicate with the second main oil circuit 46 respectively. One end of the second main oil circuit 46 in the oil separator 4 communicates with the oil injection machine 2 through the oil supply main pipe 3, and the other end is blocked with a plug.

[0071] Each outlet 83 of the solenoid valve 80 in the control valve group 8 communicates with the second spool port 49 on the corresponding oil separator 4 through the branch pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com