Electric control noninvasive installation type buoy level meter

A buoy liquid level gauge and electronic control technology, applied in the direction of the buoy liquid level indicator, etc., can solve the problems of relatively high installation position requirements, special tools required for disassembly and assembly, and limited installation methods, and achieve low installation position requirements. Quick loading and unloading, a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

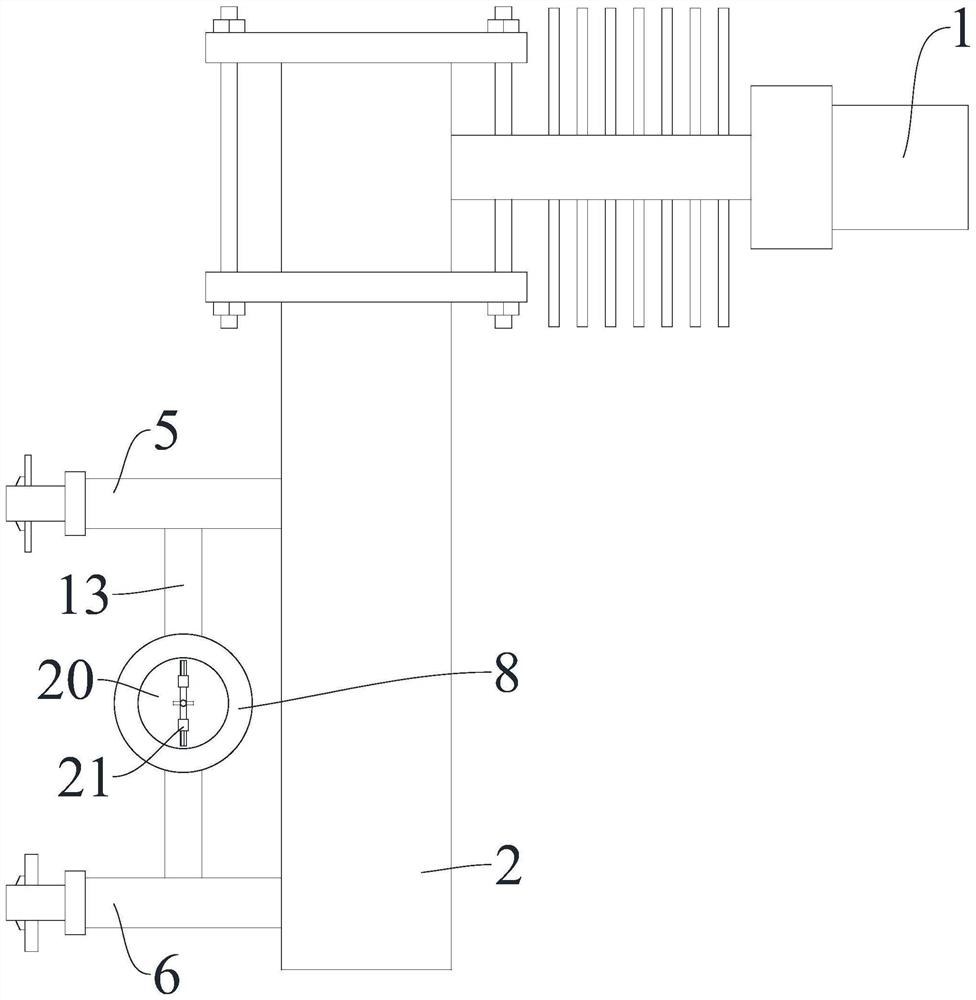

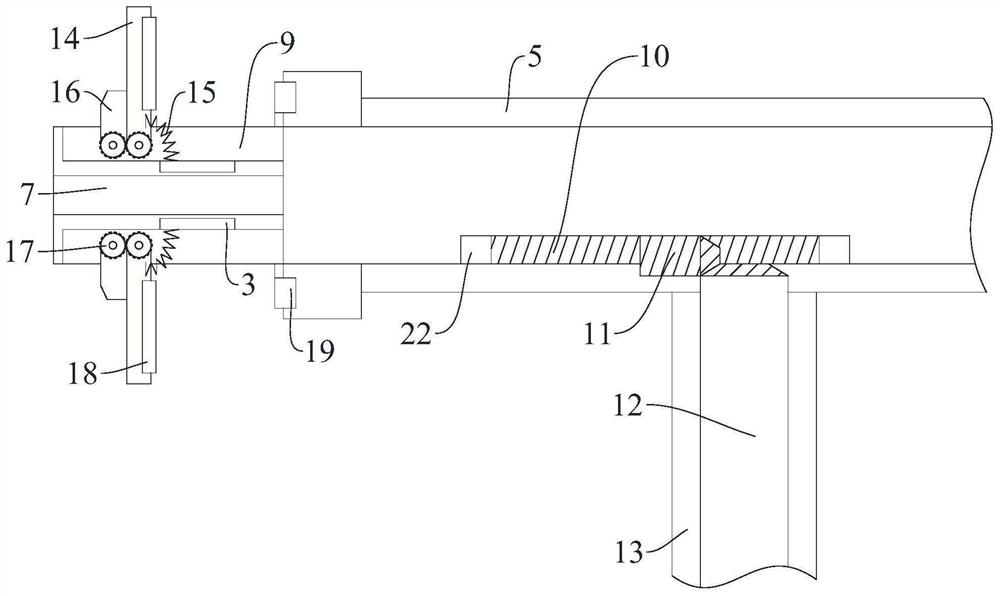

[0024] Embodiment: The electromagnet 3 and the regulating motor 4 control the opening and closing through an external power supply, and the function of the electromagnet 3 is to control the elastic flipping control bracket to flip and reset to facilitate disassembly.

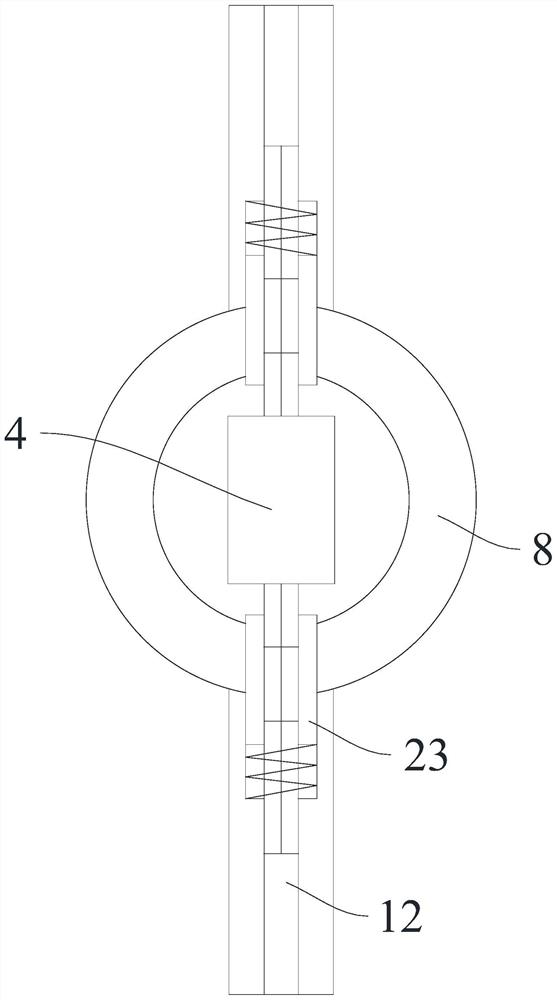

[0025] Further, in order to cooperate with lateral adjustment, the upper and lower ends of the longitudinal installation box 8 have longitudinal assembly pipes 13 for installing the internal transmission shaft 12, and the connecting ends of the threaded transmission shaft 11 and the internal transmission shaft 12 have bevel gears that mesh with each other The threaded transmission shaft 11 is threadedly engaged with the inner surface of the arc-shaped transmission groove 10, and the adjustment motor 4 controls the translation adjustment of the internal telescopic adjustment tube 7 through the internal transmission shaft 12 and the threaded transmission shaft 11.

[0026] Further, in order to cooperate with intern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com