Pole piece for soft package button battery, button battery and preparation method thereof

A technology of button batteries and soft packs, applied in the direction of electrode carriers/collectors, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of reducing battery volume energy density, increasing cell diameter, electrolyte leakage, etc., to achieve Improve the welding method and bending method, reduce the difficulty of production, and improve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

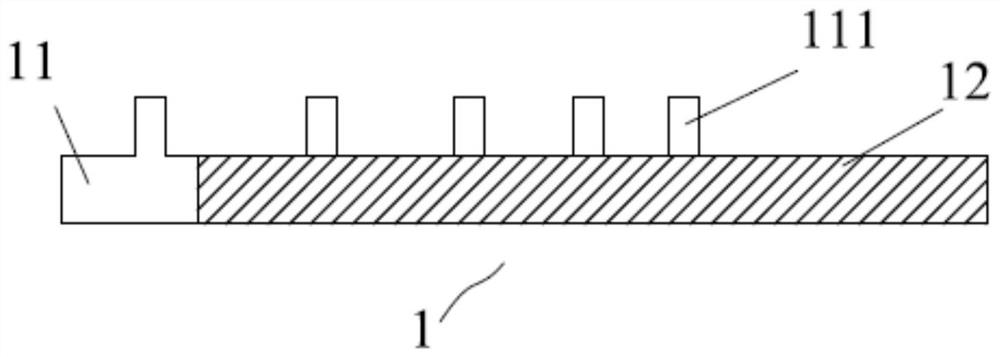

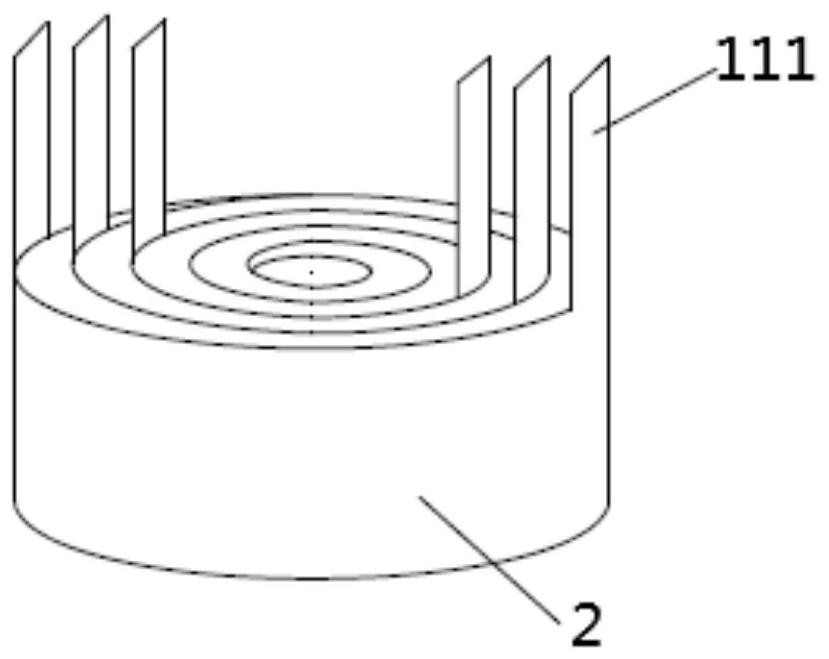

[0038] Such as figure 2 As shown, a pole piece for a soft-pack button battery includes a current collector 11, an active material layer 12 and a tab 13; the current collector 11 includes a current collector body and at least one foil 111 protruding from the collector body; the active The material layer 12 is coated on the current collector main body; the tab 13 is welded to the foil 111 , one end exposed outside the pouch button battery, and at least a part of the foil 111 is reserved between the current collector main body for bending.

[0039] Wherein, at least one protruding foil material 111 can be cut out at one end of the pole piece 1 firstly, and the ways of cutting the foil material 111 include punching, roll cutting and laser cutting. When cutting a plurality of protruding foil materials 111, the gaps between adjacent foil materials 111 can be different, but it should be kept that the plurality of foil materials 111 are arranged correspondingly after the battery is w...

Embodiment 2

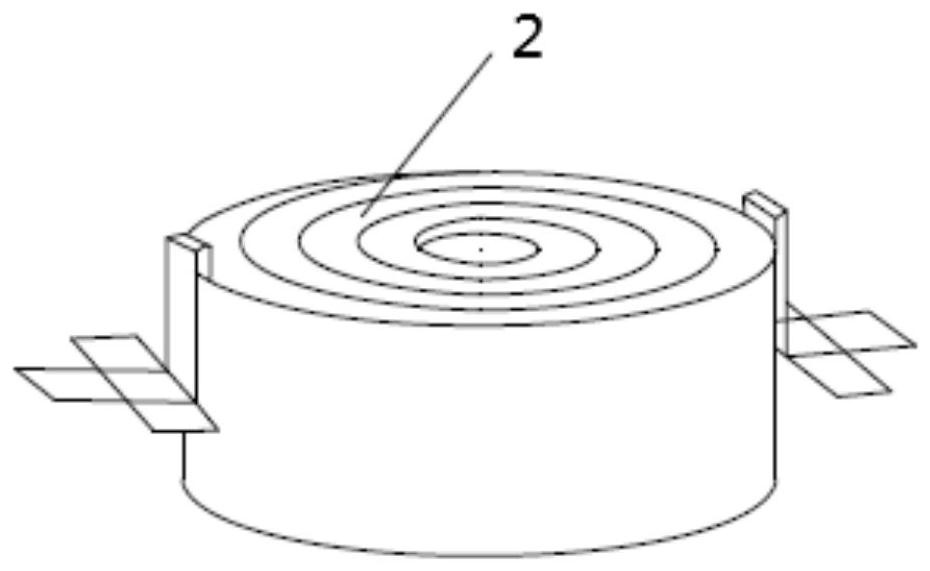

[0044] Such as Figure 3-8 As shown, a button battery includes an electric core 2 made of a positive electrode sheet, a separator and a negative electrode sheet, and the positive electrode sheet and / or the negative electrode sheet are the pole sheet 1 for a soft-pack button battery described in Example 1 .

[0045] Further, the tab 13 welded on the positive electrode sheet is a positive tab, and the tab 13 welded on the negative electrode sheet is a negative tab, and the positive tab and the negative tab are drawn out from the same end or both ends of the cell 2 . The specific lead-out method of the positive and negative tabs can be determined according to the direction of the foil 111 set in the positive and negative electrodes. The two lead-out methods can be respectively referred to Figure 3-5 and Figure 6-8 shown.

[0046] Further, the bent portion of the foil 111 is flattened to the end surface of the cell 2 . Because the material of the foil 111 is relatively soft,...

Embodiment 3

[0050] A preparation method for a button battery, comprising the steps of:

[0051] S1. Cut out at least one foil 111 protruding from the main body of the positive current collector on the positive current collector, and coat the positive active material layer 12 on the main body of the positive current collector to obtain a positive electrode sheet; cut out on the negative current collector At least one foil 111 protruding from the main body of the negative electrode current collector, and coating the negative electrode active material layer 12 on the negative electrode current collector 11 to obtain a negative electrode sheet;

[0052] S2. The battery cell 2 is prepared by sequentially winding the positive electrode sheet, the separator and the negative electrode sheet, and the foil material 111 of the positive electrode current collector and the foil material 111 of the negative electrode current collector are partially exposed outside the battery cell 2;

[0053] S3. Weld ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap