Hair cutting appliance

一种毛发切割、器具的技术,应用在金属加工等方向,能够解决影响切割单元机械工作切割系统寿命等问题,达到优化切割性能或磨损和能量损失、避免摩擦力的变化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

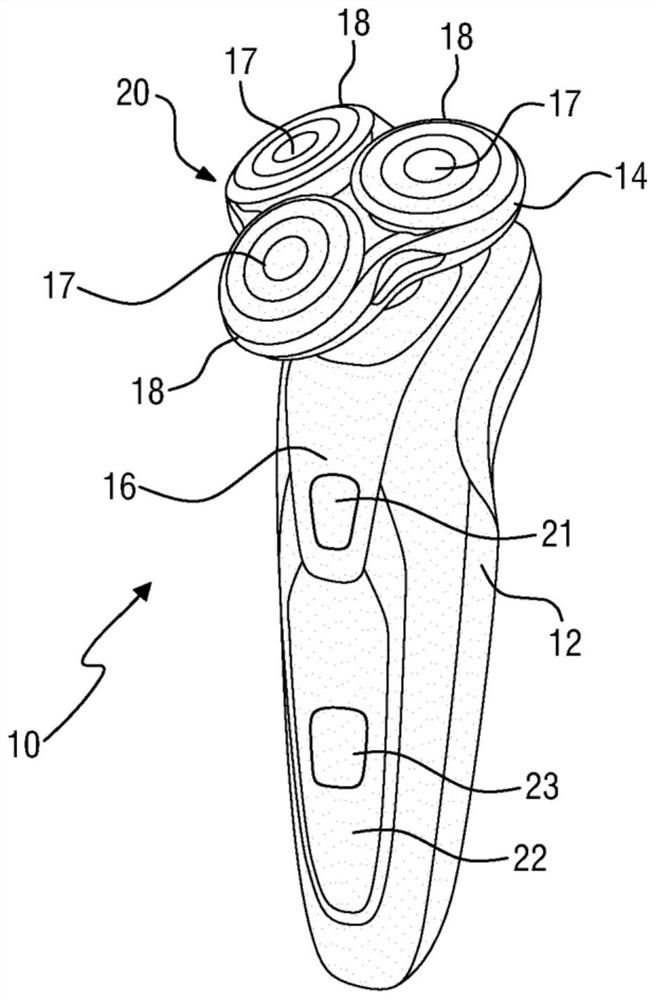

[0065] figure 1 A perspective top view of a hair cutting device 10 configured as a shaver is shown. The hair cutting device 10 comprises an elongated main housing 12 and a hair cutting appliance configured as a shaving unit 20 arranged at a top end of the main housing 12 . The shaving unit 20 comprises a cutting head 14 with three cutting units 17 arranged in a somewhat triangular fashion.

[0066] In the main housing 12, a driver 16 (not shown in detail here) is accommodated. The drive 16 is configured to operate and actuate the shaving unit 20 by means of at least one drive spindle, which will be explained below with reference to the following figures. At the main housing 12, other components of the hair cutting device 10 may be provided, such as operator controls, an on-off switch 21, external setting pads 23, batteries, sockets for cables etc.

[0067] The shaving unit 20 is altogether removable from the hair cutting device 10 comprising the main housing 12, the drive 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com