Self-repairing solid electrolyte, preparation method and application thereof

A solid-state electrolyte and self-repairing technology, which is applied in the direction of solid electrolyte, non-aqueous electrolyte, non-aqueous electrolyte battery, etc., can solve the problems of poor stability and low applicability of solid-state batteries, and achieve simple preparation process, low cost and easy availability, Process green effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

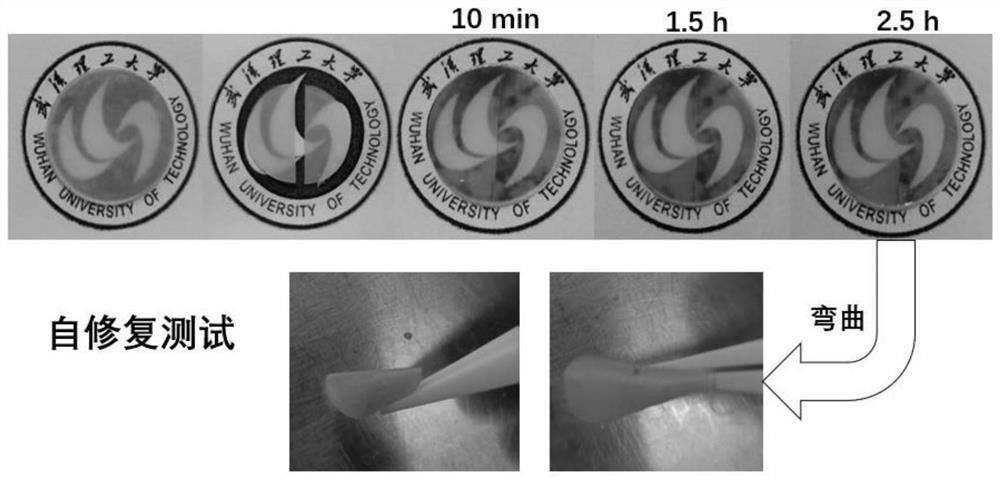

[0040] In order to solve the above problems, combined with figure 1 , Figure 6 As shown, the embodiment of the present invention provides a method for preparing a self-healing solid electrolyte, and the specific steps are:

[0041] S1, mixing the dissociated lithium salt compound with a solvent, and ultrasonically obtaining a dissociated solution;

[0042] S2. Add the self-healing polymer, cross-linking agent, and lithium salt into the dissociation solution, mix evenly, and heat up to react to obtain a self-healing precursor solution;

[0043] S3. Put the self-healing precursor solution on a polytetrafluoroethylene plate to form a film, and dry it in vacuum to obtain a self-healing solid electrolyte.

[0044] Specifically, in step S1, the dissociated lithium salt compound includes polyethylene glycol, polyvinylidene fluoride, polyvinylidene fluoride-hexafluoropropylene, polyethylene oxide, polypropylene oxide, polypropylene carbonate, poly( At least one of ethylene glycol)...

Embodiment 1

[0060] This embodiment provides a method for preparing a self-healing solid electrolyte, and the specific steps are as follows:

[0061] 1) Preparation of dissociation solution

[0062] 2 g of polyvinylidene fluoride and N-N dimethylformamide (treated with molecular sieves) were uniformly mixed to obtain a dissociation solution.

[0063] 2) Preparation of self-healing precursor solution

[0064] Add 4g of DL-α-lipoic acid, 0.4g of 1,3-diisopropenylbenzene and 0.2g of polyethylene glycol diacrylate to the above dissociation solution, react and stir at 75°C for 10 minutes, then Add 10 mg of anhydrous ferric chloride, and continue heating for a period of time until the anhydrous ferric chloride is completely dissolved in the solution; after cooling to room temperature, add 0.2 g of lithium perchlorate, and stir for 12 hours to obtain a self-repairing precursor solution.

[0065] 3) Preparation of self-healing solid electrolyte

[0066] The self-healing precursor solution was p...

Embodiment 2

[0068] The difference between this embodiment and Embodiment 1 is that this embodiment provides a method for preparing a self-healing solid electrolyte, and the specific steps are as follows:

[0069] 1) Preparation of dissociation solution

[0070] Mix 3 g of polyvinylidene fluoride-hexafluoropropylene and acetonitrile evenly to obtain a dissociation solution.

[0071] 2) Preparation of self-healing precursor solution

[0072] Dissolve 188 mg of lithium bistrifluoromethylsulfonylimide in 812 mg of 1-allyl-3-vinylimidazole bistrifluoromethylsulfonimide salt, stir for 2 hours, and form a lithium salt mixture.

[0073] Add 6g of DL-α-lipoic acid and 1g of lithium salt mixture into the dissociation solution, stir evenly, and after heating at 75°C for 10 minutes, inject 1.2g of 1,3-diisopropenylbenzene and 15mg of Anhydrous ferric chloride was continued to be heated at 75° C. for 30 minutes to obtain a self-repairing precursor solution.

[0074] 3) Preparation of self-healing s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com