Closing tool special for flame tube assembly and use method of closing tool special for flame tube assembly

A flame cylinder and tool technology, which is applied in the field of special closing tools for flame cylinder assembly, can solve the problems of unsatisfactory effect, low pass rate, poor quality, etc., and achieve great application value, increase close pass rate, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

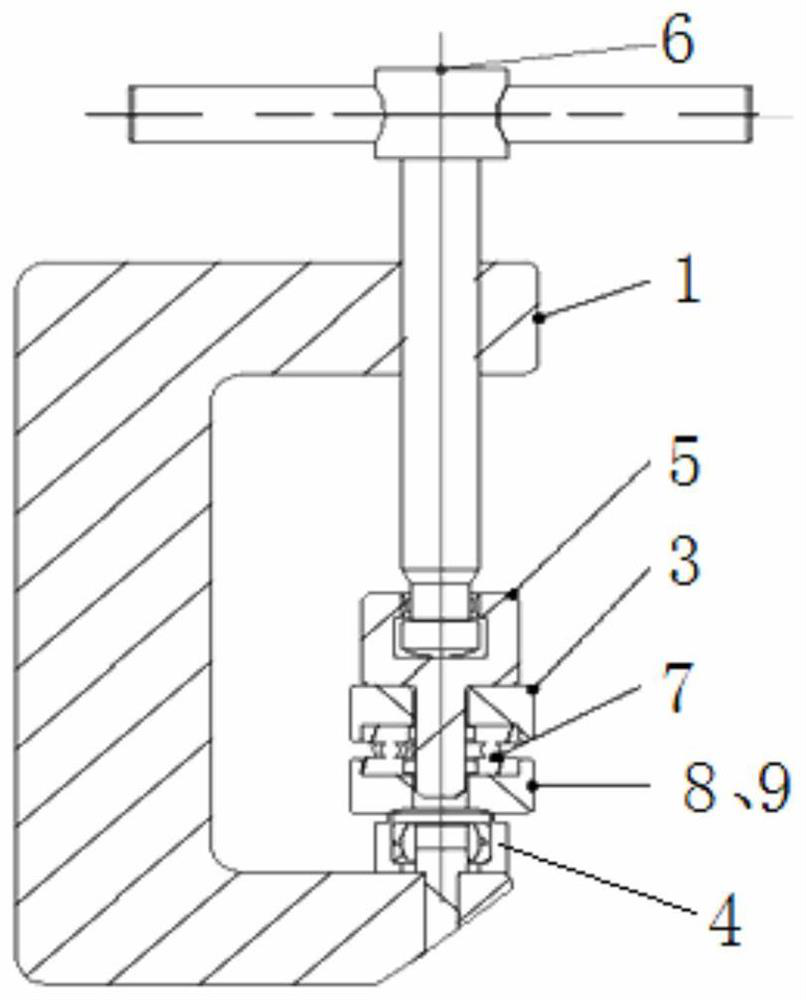

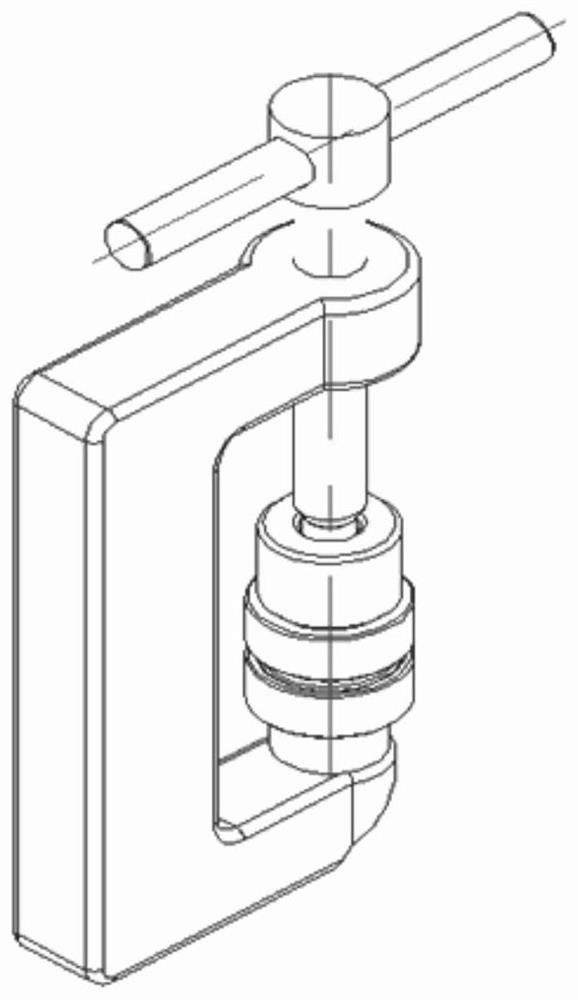

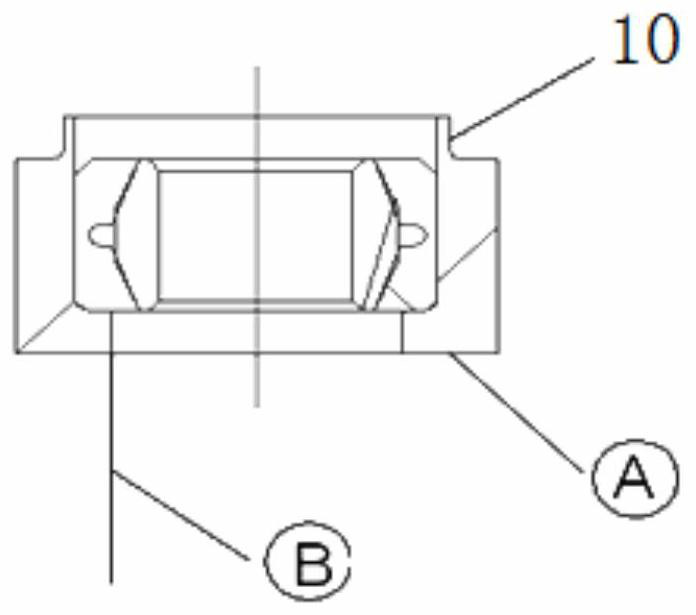

[0029] Such as Figure 1-4 As shown, a special closing tool for assembling a flame tube, including a C-shaped clamp device, a ejector rod device and a block device;

[0030] The C-shaped clamp device is composed of a C-shaped clamp 1 and a positioning column 2. The C-shaped clamp 1 is provided with two coaxial mounting holes symmetrically up and down, and the mounting hole at the upper end is provided with threads for connecting the transmission ejector rod 3 ; The positioning column 2 is fastened in the installation hole at the lower end of the C-shaped clamp 1, and is used for positioning the part 4;

[0031] The push rod device is composed of a push rod 3, a push rod block 5, a C-type movable handle compression screw 6 and a bearing 7;

[0032] The top of the C-type movable handle compression screw 6 is in contact with a small gap between the push rod 3 and can rotate freely;

[0033] The front end of the ejector pin 3 is inserted into the ejector pin block 5 through a sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com