Rail hoisting structure and suspension type rail transit system

A technology of rail cranes and rails, which is applied to the elevated railway systems, tracks, roads and other directions using suspended vehicles, can solve the problems that the tracks are prone to torsion and have potential safety hazards, and achieve the effect of reducing potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

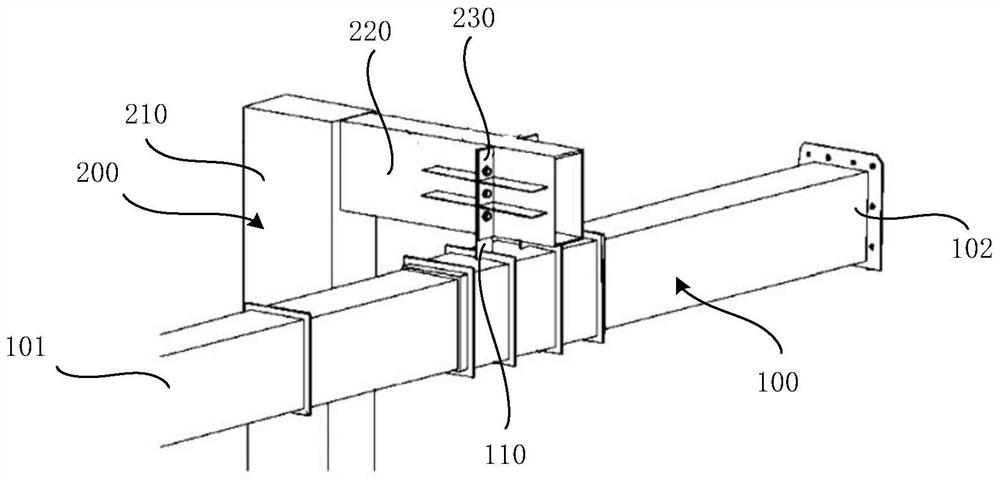

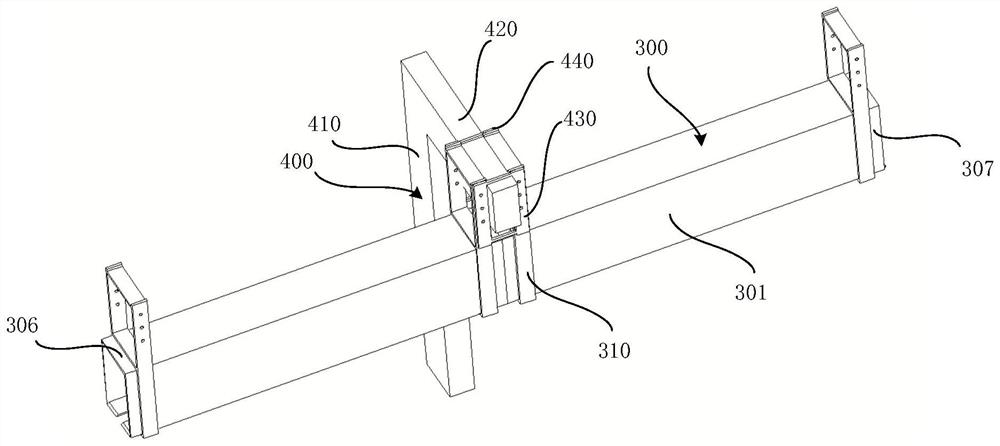

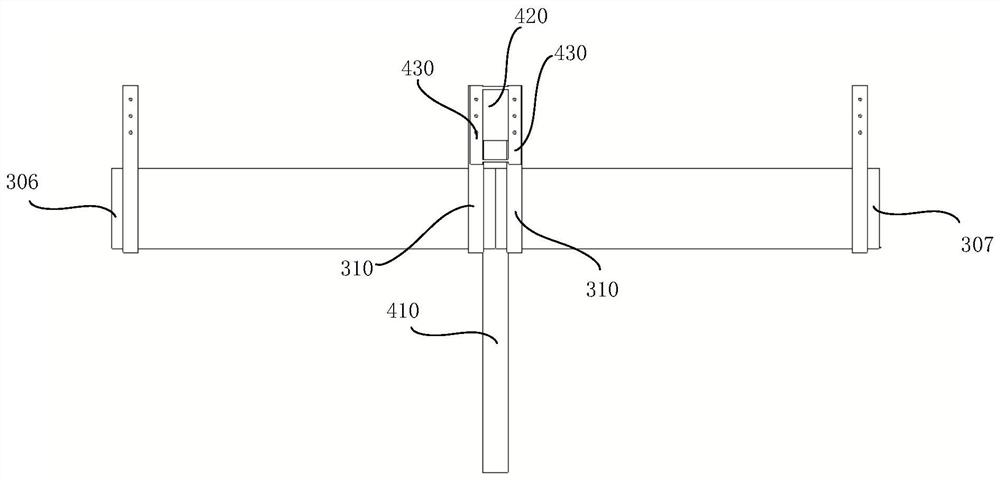

[0044] figure 2 Shown in is a schematic diagram of the rail hoisting structure provided by an embodiment of the present application; image 3 shown in figure 2 A schematic diagram of the main view structure; Figure 4 Shown in is a schematic structural diagram of the track provided by an embodiment of the present application; Figure 5 Shown in is a schematic structural diagram of the first fixing device provided by an embodiment of the present application; Image 6 Shown in is a schematic structural diagram of a supporting device provided by an embodiment of the present application; please refer to Figure 2-Figure 6 .

[0045] This embodiment provides a rail hoisting structure, including a rail 300 and a supporting device 400, wherein the rail 300 is used to provide a running path for a rail vehicle, so that the rail vehicle can move along the rail 300; The fixed support is in the space above the ground to relieve the pressure of ground transportation.

[0046] Optio...

Embodiment 2

[0068] This embodiment provides a suspended rail transit system, including a rail vehicle and the rail hoisting structure described in Embodiment 1 above.

[0069] Specifically, the rail vehicle can be connected to the running device arranged inside the track through the hanging device passing through the opening, and the running device can drive the rail vehicle to move along the track. The rail transit system also includes structures such as dispatching rooms and platforms scattered around the track.

[0070] Since the suspended rail transit system of this embodiment adopts the rail hoisting structure of the above-mentioned embodiment 1, the rail is less likely to be twisted during operation, and the safety is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com