Blasting Vibration Reduction Construction Method of Multiple Pilot Tunnel and Preset Composite Vibration Isolation Layer Close to Tunnel

A construction method and tunnel technology, applied in tunnels, blasting, tunnel lining, etc., can solve the problems of interlayer surrounding rock, limited access surface, and reduced construction efficiency in excessive disturbance, and achieve a reduction in blasting vibration speed and a significant vibration isolation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

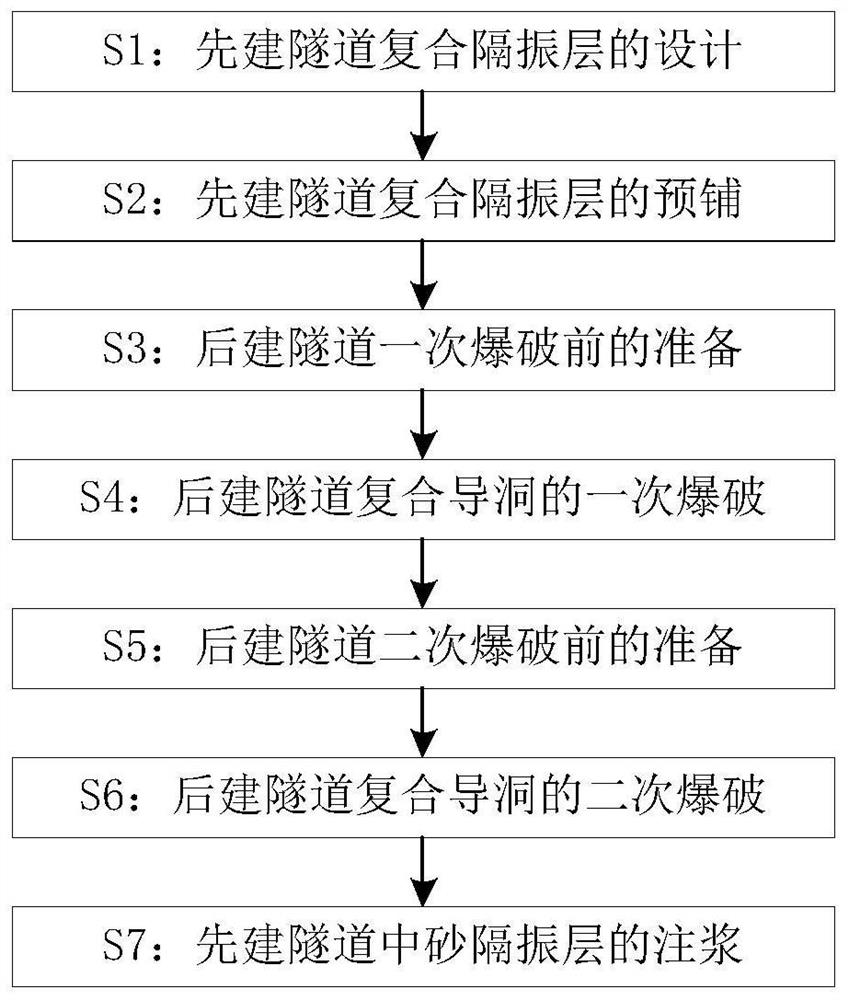

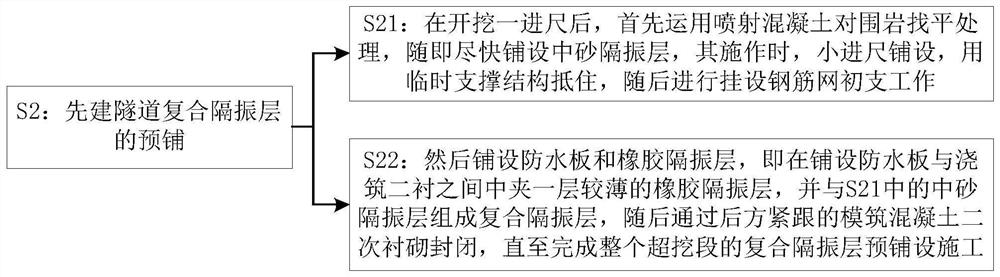

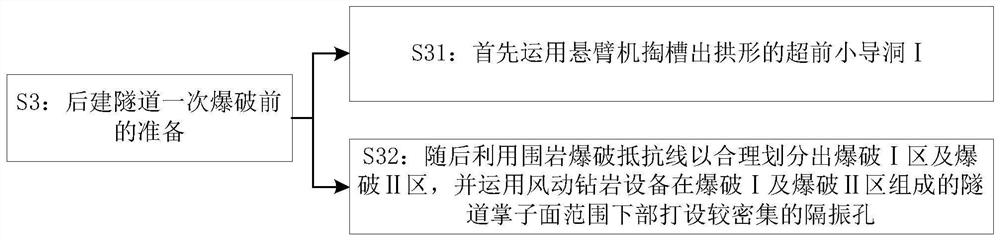

[0065] Such as figure 1 As shown, the multiple pilot tunnel and the preset composite vibration isolation layer of the present invention are close to the blasting vibration reduction construction method of the tunnel, including the following steps:

[0066] S1: Design of the composite vibration isolation layer of the first-built tunnel: According to the construction organization design, before the first-built tunnel 8 passes through the blasting-affected area, it is necessary to judge the intersection angle of the first-built tunnel 8 and the second-built tunnel 9, as follows: Figure 11 As shown, namely:

[0067] When the intersection angle of the tunnel exceeds 60°, the composite vibration isolation layer 10 is respectively laid in the direction of the two tunnels at the closest distance point;

[0068] When the tunnel intersection angle is less than 60°, the laying length of the vibration isolation layer should be extended appropriately depending on the working conditions; ...

Embodiment 2

[0087] In the following, the blasting of the post-constructed tunnel 9 will be described in combination with a specific case.

[0088] Assuming that the surrounding rock 101 around the tunnel is grade III, the first tunnel 8 and the later tunnel 9 will be constructed at the three-dimensional intersection, and the horizontal intersection angle of the two tunnels will be 80°. , the cycle footage is 2m, the blasting material uses plastic nonel, the initiation system is a non-electric millisecond detonator system, the electric detonator is detonated, and the peripheral eye uses small-diameter 40mm rock ammonium nitrate explosives; the selection process of the blasting parameters is as follows:

[0089] Step 1: Take the minimum resistance line of rock as W=1.75m, and calculate the blasting action index:

[0090]

[0091] Step 2: Take the unit explosive consumption as 1.5 after correction according to relevant norms and empirical formulas.

[0092] Step 3: Take 0.90 according to...

Embodiment 3

[0109] The composite vibration isolation layer 10 of the previously built tunnel 8 will be described below in conjunction with a specific case.

[0110] Assuming that the intersection angle between the first tunnel 8 and the later tunnel 9 exceeds 60°, the composite vibration-isolation layer 10 is arranged at a length extending 15m to both sides of the nearest point.

[0111] The type and thickness of each layer of the composite vibration isolation layer 10 are shown in the parameters in the table.

[0112] Table 2 Design parameter list of composite vibration isolation layer 10

[0113]

[0114]The laying position of the composite vibration isolation layer 10 is as attached Figure 12 Shown:

[0115] The beneficial effects of the present invention are: (1) the excavation structure of the face of the multiple pilot tunnel avoids the high peak vibration velocity when the cutting blast creates the free surface, and the creation degree of the free surface is far greater than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com