Microwave heating type heat exchange device and method

A microwave heating and heat exchange device technology, applied in the direction of microwave heating, etc., can solve the problems of reduced production efficiency, influence of process production, large heat loss, etc., and achieve the effect of improving production efficiency and avoiding heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

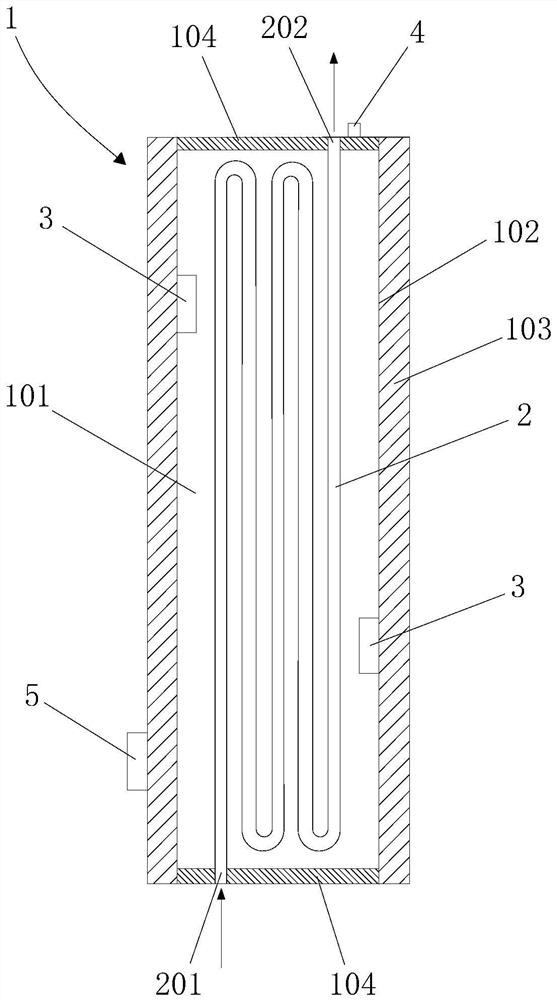

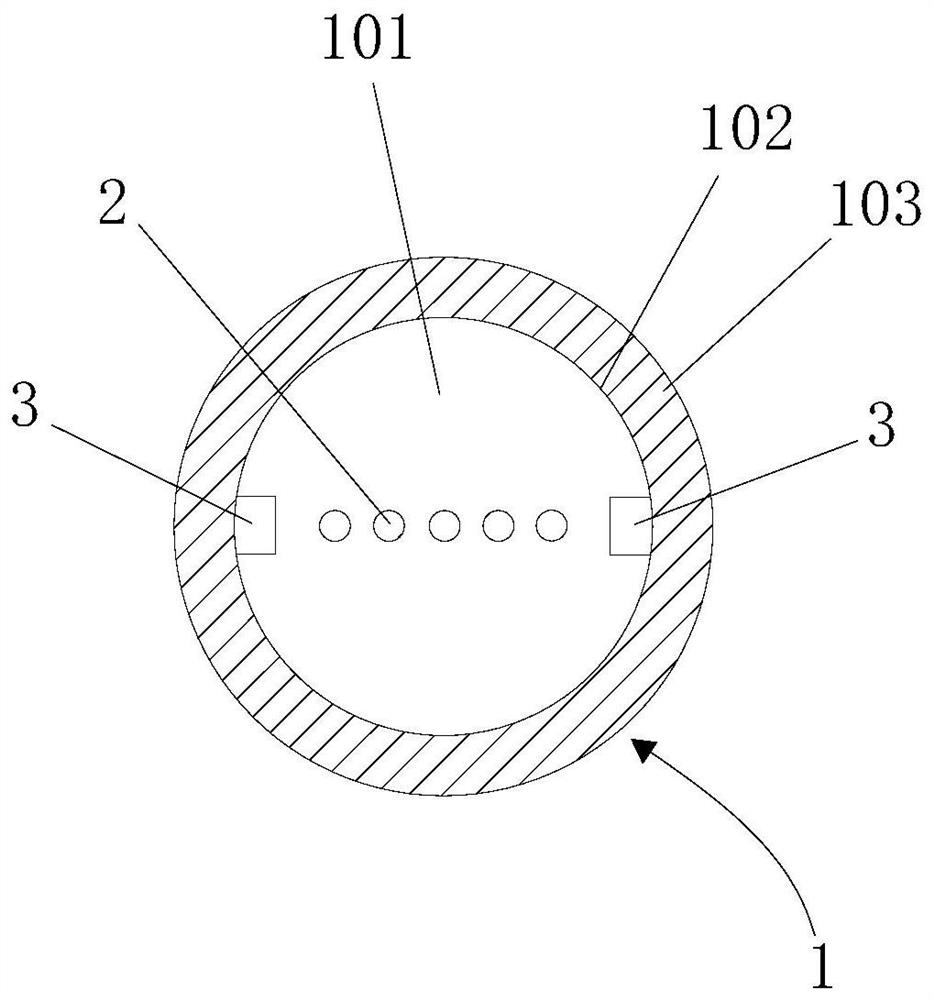

[0039] Such as figure 1 , figure 2 As shown, the present invention provides a microwave heating type heat exchange device, the microwave heating type heat exchange device includes a shell 1, an inner tank 2 and a microwave source assembly 3, wherein: a sealed heat exchange chamber is formed inside the shell 1 101, the inner tank 2 and the microwave source assembly 3 are both arranged in the heat exchange chamber 101, the inner tank 2 and the heat exchange chamber 101 are sealed and connected, the inner tank 2 is provided with a material inlet 201 and a material outlet 202, and the material The inlet 201 and the material outlet 202 are respectively connected with the outside of the heat exchange chamber 101, the material enters the inner tank 2 through the material inlet 201, and is output to the outside through the material outlet 202; A microwave electric field is established in the chamber 101 , and the microwaves in the microwave electric field heat the liner 2 to exchang...

Embodiment approach 2

[0059] The present invention provides a microwave heating type heat exchange method. In the method, the microwave emitted by the microwave source assembly 3 heats the inner container 2, and heat exchange is performed between the material and the inner container 2 during the process of the material passing through the inner container 2, and the material By absorbing the heat and radiation energy of the inner tank 2, the temperature of the material is raised.

[0060] In this method, the liner 2 is located in a closed heat exchange chamber 101 to transport materials, and the microwaves emitted by the microwave source assembly 3 establish a microwave electric field in the heat exchange chamber 101 .

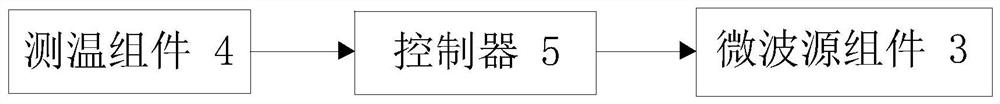

[0061] In this method, the temperature of the heated material is detected by the temperature measuring component 4, and the intensity of the microwave source component 3 is controlled according to the detection result.

[0062] The specific flow of this method is described below:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com