Crayfish shell recycling, drying and dehydrating device

A dehydration device, lobster technology, applied in cleaning device, dry preservation of meat/fish, application, etc., can solve the problems of insufficient drying, can not meet the drying demand, etc., to improve the completeness of crushing, increase the drying heating area, improve The effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

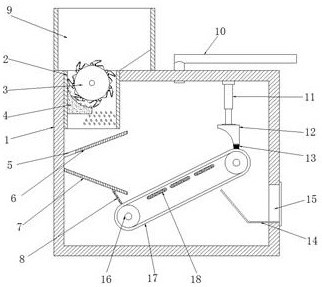

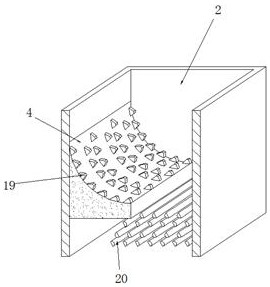

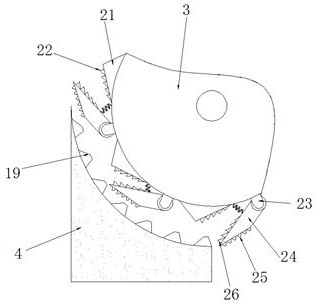

[0027] refer to Figure 1-4 , a drying and dehydrating device for recycling crayfish shrimp shells, comprising a box body 1, a hopper 9 is fixed on the left side of the top outer wall of the box body 1, and a material guide pipe 2 is fixedly inserted between the hopper 9 and the box body 1, A runner 3 is installed to rotate in the material guide pipe 2, and a plurality of equidistantly distributed hinge shafts 23 are hinged and fixed on the circumference outer wall of the runner 3, and a crushing plate 24 is installed on the hinge shaft 23, and the crushing plate 24 is connected to the rotating shaft. Springs are fixed between the outer walls of the wheels 3, and the outer walls of the outer walls of the runner 3 are fixed with triangular bumps 21 with the same number as the crushing plates 24. The first triangular teeth 22, the second triangular teeth 26 equidistantly distributed are fixed on the inner side of the crushing plate 24, and the rolling table 4 adapted to the runn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com