A blood processing device for blood transfusion department

A technology of blood processing and air extraction device, which is applied in the direction of centrifuges, etc., can solve the problems of heavy workload and increased infection, and achieve the effects of reducing workload, reducing the probability of infection, energy saving, environmental protection, weight and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

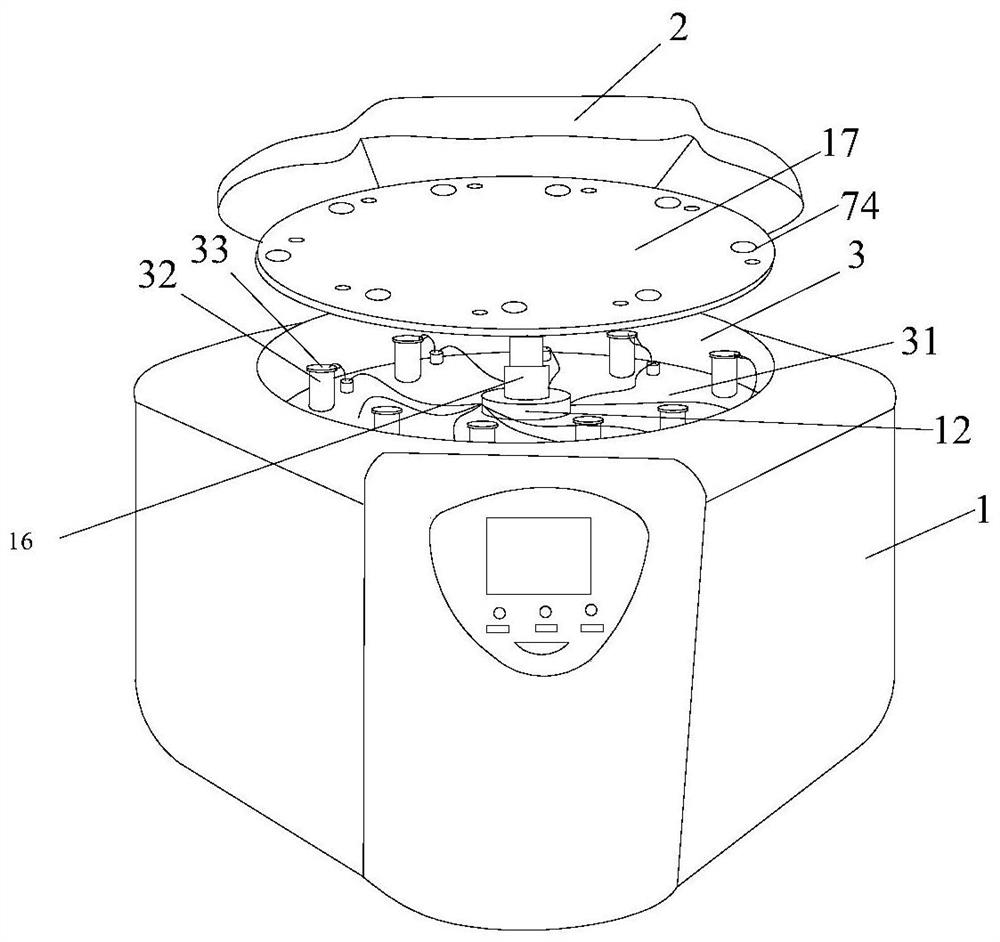

[0042] Such as figure 1 As shown, a blood treatment device for blood transfusion provided by this embodiment includes an outer shell 1, on which a cover 2 is hinged; a centrifuge chamber 3, which is arranged in the outer shell 1, and a centrifuge tube mounting frame 31 is arranged inside, The centrifuge tube 32 is fixed on the centrifuge tube mounting frame 31; the motor is located at the bottom of the centrifuge chamber 3 for rotating the centrifuge chamber 3;

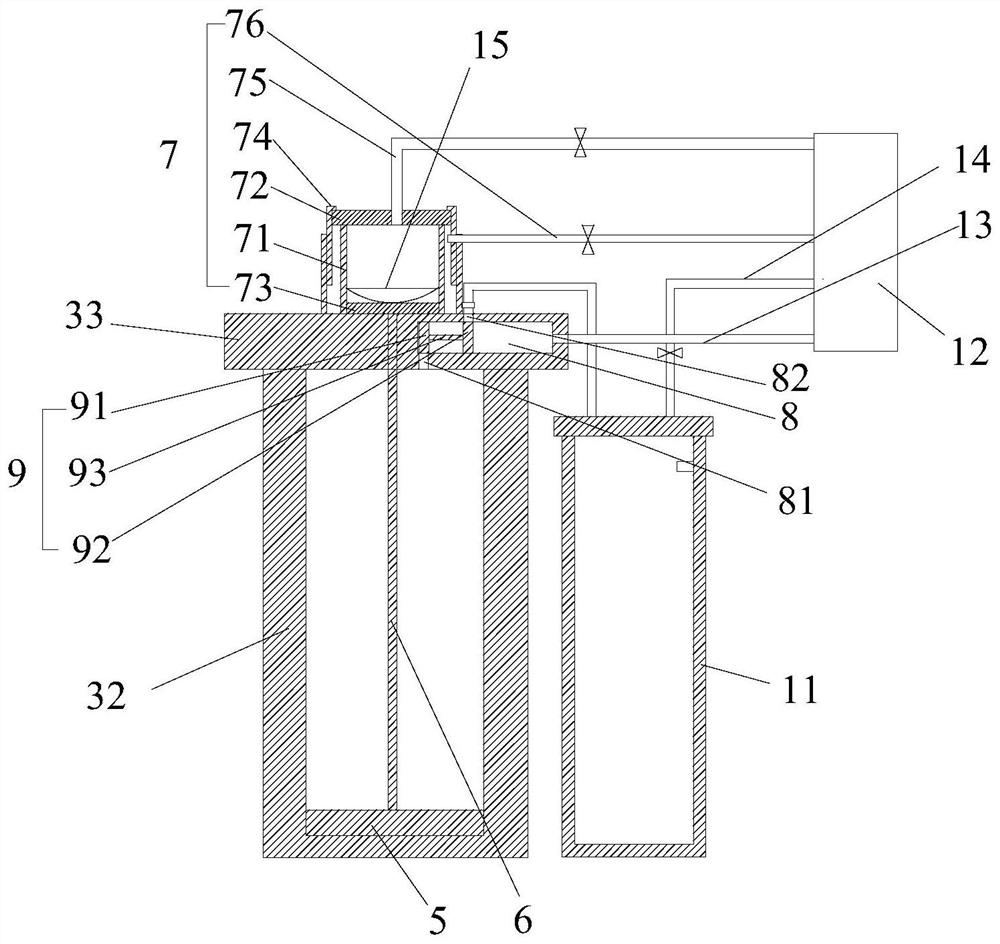

[0043] Such as figure 2 As shown, it also includes a packing mechanism, which includes a first piston head 5, which is arranged in the centrifuge tube 32; a piston rod 6, which is connected with the first piston head 5, and the tube of the centrifuge tube 32 The cover 33 is provided with a via hole for the piston rod 6 to pass through, and the piston rod 6 is in sealing connection with the via hole on the tube cover 33; the piston driving mechanism 7 is used to drive the first piston head 5 to move up and down; the ...

Embodiment 2

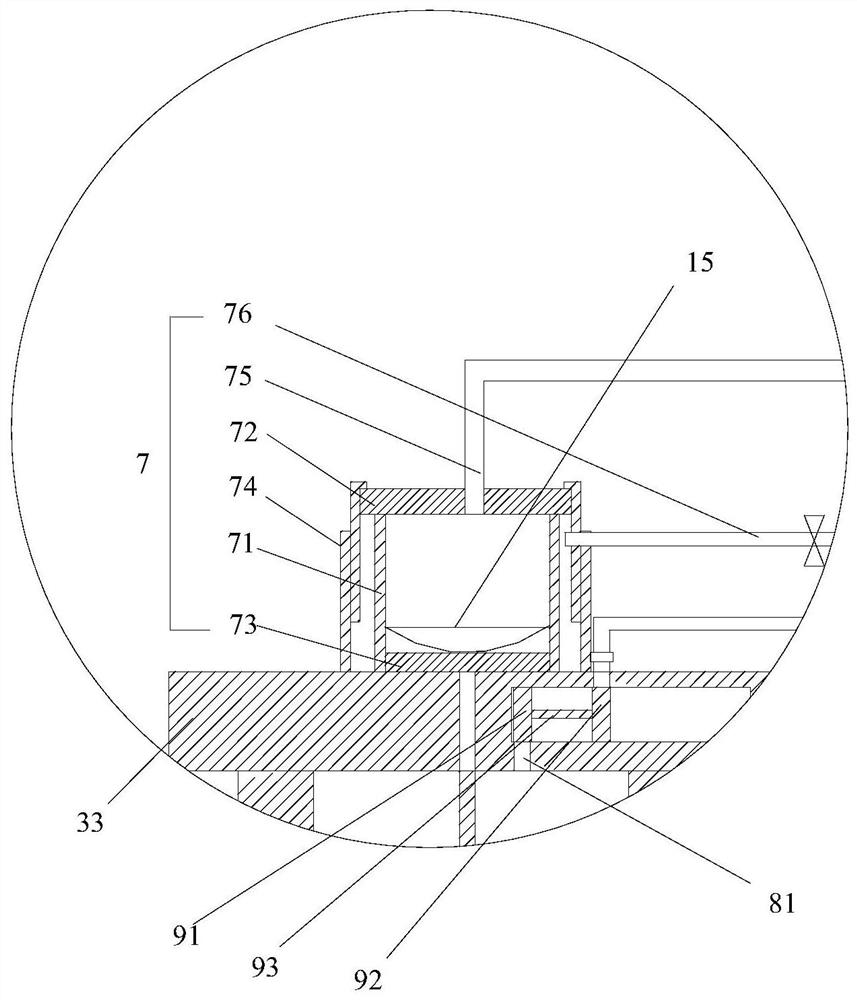

[0048] On the basis of Example 1, such as figure 2 and image 3 As shown, the piston driving mechanism 7 includes a first sealing cylinder 71, the top of which is provided with a sealing plate 72; a second piston head 73 is located in the first sealing cylinder 71, and the second piston head 73 can be connected to the piston The rod 6 is clamped; the second sealing cylinder 74 is arranged on the outside of the first sealing cylinder 71, and the second sealing cylinder 74 is formed by sealing and socketing a plurality of sleeves, and the sealing plate 72 and the second sealing cylinder The top of the sealing cylinder 74 is fixedly connected, and the bottom of the second sealing cylinder 74 is clamped with the tube cover 33; the top of the first sealing cylinder 71 is connected with the inflation and suction device 12 through the first connecting pipe 75 for making the The second piston head 73 moves upward in the state of pumping air, and moves downward in the state of inflat...

Embodiment 3

[0053] On the basis of the above-mentioned embodiments, as Figure 4 As shown, the length of the separation channel 8 is sufficient to accommodate at least two plugging plugs 9, and the plugging plug 9 includes a first plugging head 91, a second plugging head 92 and a connecting rod 93, and the first plugging head 91 and the second plugging head 92 are respectively fixed on the two ends of the connecting rod 93, and the first plugging head 91, the second plugging head 92 and the inner wall of the separation channel 8 are sealed and connected, and the separation channel 8 is close to the pipe cover 33 One end of the outer edge is connected to the inflation and suction device 12 through the third connection pipe 13, and the dispensing pipe 11 is connected to the inflation and suction device 12 through the fourth connection pipe 14. Two electromagnetic valves, the liquid inlet 81 is provided with a density sensor, and the second electromagnetic valve and the density sensor are bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com