Processing equipment for self-compacting concrete

A self-compacting concrete and processing equipment technology, applied in the processing of building materials, sustainable waste treatment, solid waste management, etc., can solve the problem that the concrete cannot be delivered to the designated position, and it is inconvenient for the driver to switch the seat angle and control the processing Equipment impact damage and other problems, to achieve the effect of increasing the load weight, not easy to wear, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

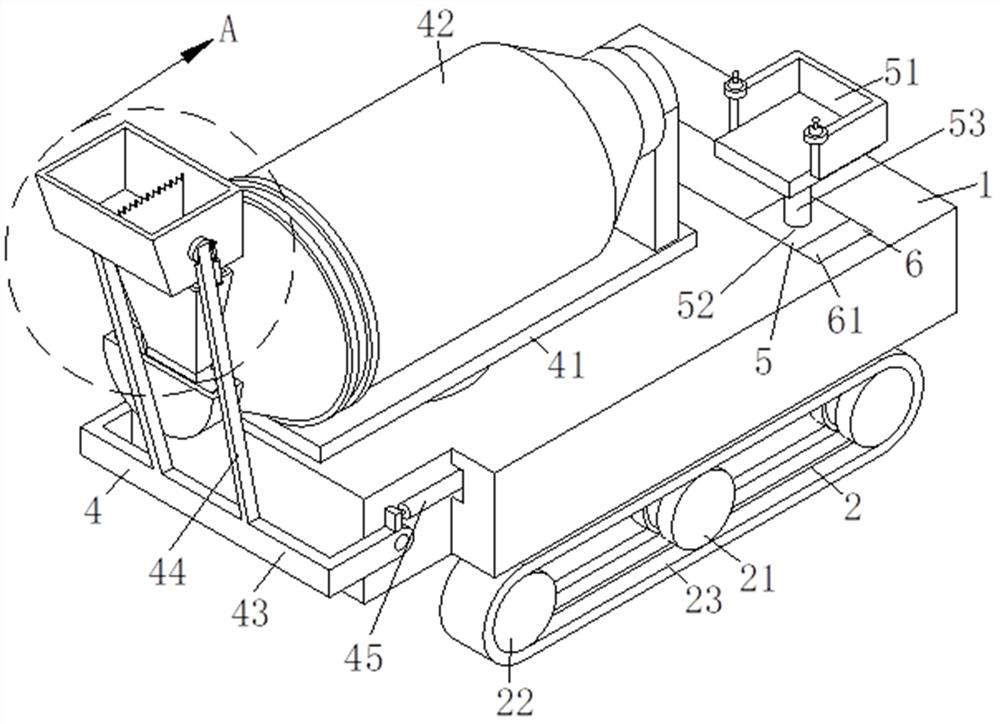

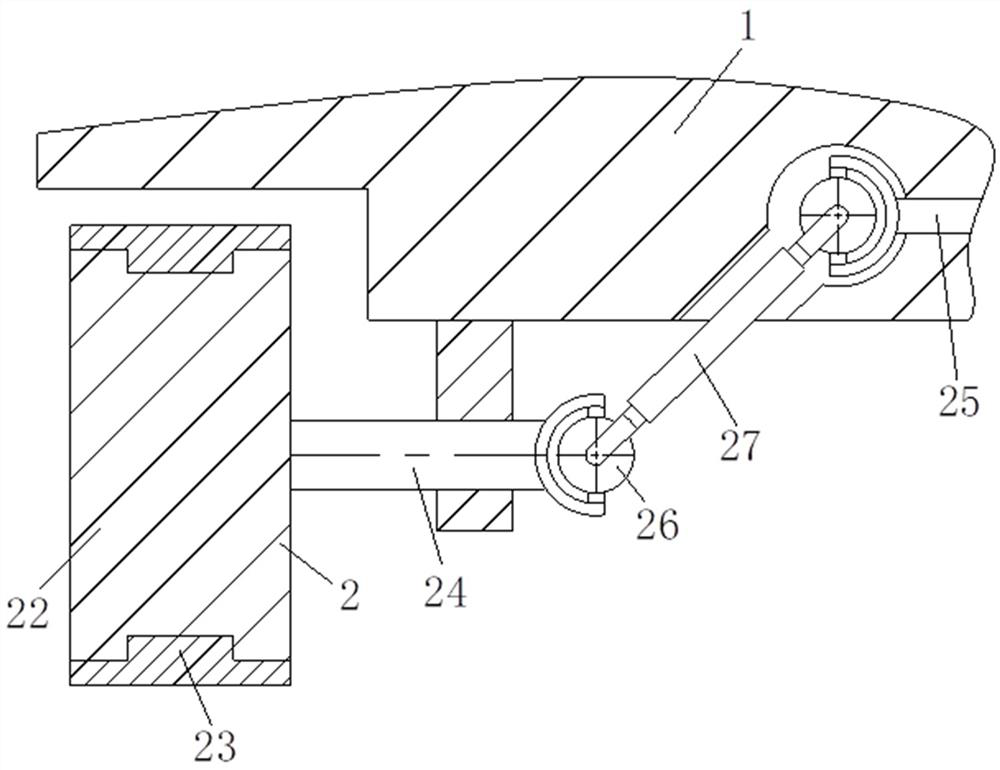

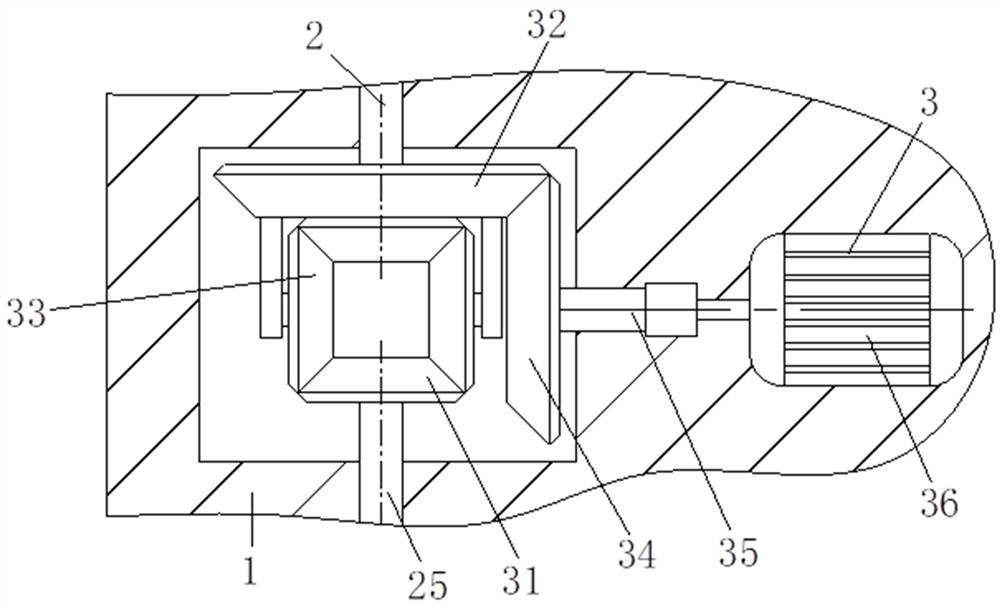

[0025] Such as Figure 1-Figure 7 As shown, a self-compacting concrete processing equipment according to the present invention includes a main body 1, a moving mechanism 2, a differential mechanism 3, a feeding mechanism 4, an observation mechanism 5 and a protection mechanism 6, which are used to drive the main body 1. The moving mechanism 2, which increases the contact area between the moving parts and the ground while moving, is arranged on both sides of the bottom end of the main body 1, and is used to provide power for the moving mechanism 2 and meet the needs of the main body 1 during driving. The differential mechanism 3 for reducing the wear and tear of moving parts is arranged inside the main body 1, and the feeding mechanism 4 for reduci...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap