Refrigerator drawer injection mold

An injection mold and drawer technology, which is applied in the field of refrigerator drawer injection molds, can solve the problems affecting product production quality, inconvenient and rapid material retrieval, and inability to quickly fill, and achieves the effects of novel design, high degree of automation, and guaranteed production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

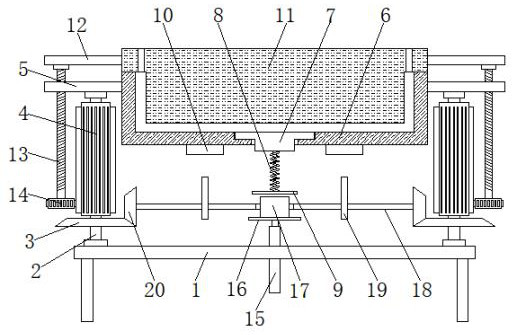

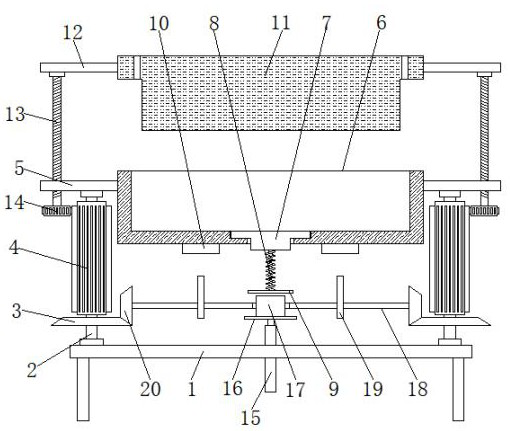

[0028] refer to Figure 1-3 , Image 6 An injection mold for a refrigerator drawer, comprising a placing plate 1, a transmission mechanism is arranged on both sides of the top of the placing plate 1, a fixed plate 5 is connected to the top of the transmission mechanism in rotation, and a lower mold 6 is fixedly connected between the two fixed plates 5, The movable cover at the bottom of the lower die 6 is provided with an ejection mechanism, the top of the lower die 6 is provided with a patrix 11, the two sides of the patrix 11 are provided with a lifting mechanism, and the inner fixed sleeve of the placing plate 1 is provided with a push rod motor 15, which pushes The output shaft of the rod motor 15 is fixedly connected with a driving vibration mechanism, and the bottom of the lower mold 6 is fixedly connected with two elastic blocks 10 .

[0029] In the present invention, the transmission mechanism includes a rotating shaft 2 that is rotatably connected to the top of the p...

Embodiment 2

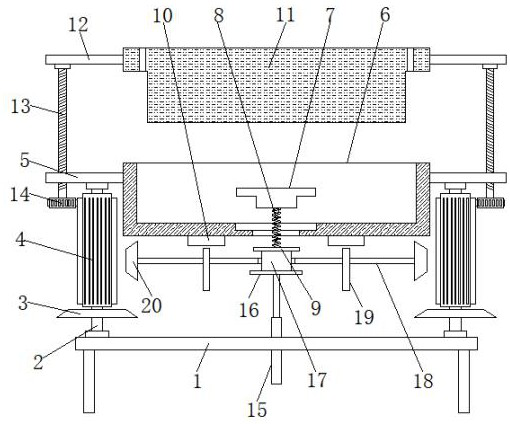

[0036] refer to Figure 3-5 : An injection mold for a refrigerator drawer. In this embodiment, after the injection molding and vibration operations are completed, the push rod motor 15 drives the driving vibration mechanism to move down again, so that the first bevel gear 3 and the second bevel gear 20 are meshed again to drive the vibration The mechanism drives the lifting mechanism to work through the transmission mechanism. The lifting mechanism will drive the upper mold 11 to move upward. At this time, the push rod motor 15 will drive the driving vibration mechanism to move upward again. The driving vibration mechanism will squeeze the ejection mechanism. The ejection mechanism includes movable sleeves. In the lifting plate 7 inside the lower die 6, the bottom of the lifting plate 7 is fixedly connected with a spring 8, and the bottom end of the spring 8 is fixedly connected with a movable plate 9, so that the movable plate 9 and the spring 8 will move upwards under the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com