Wind power hoisting tower crane truss type underframe suitable for all-terrain weak ground pressure and tilt resistance

A technology for hoisting tower cranes and anti-tilting, which is applied in cranes, buildings, infrastructure engineering, etc., can solve the problems of difficult installation, high cost, and low cost, and achieve the effect of light structure, convenient transition, and easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

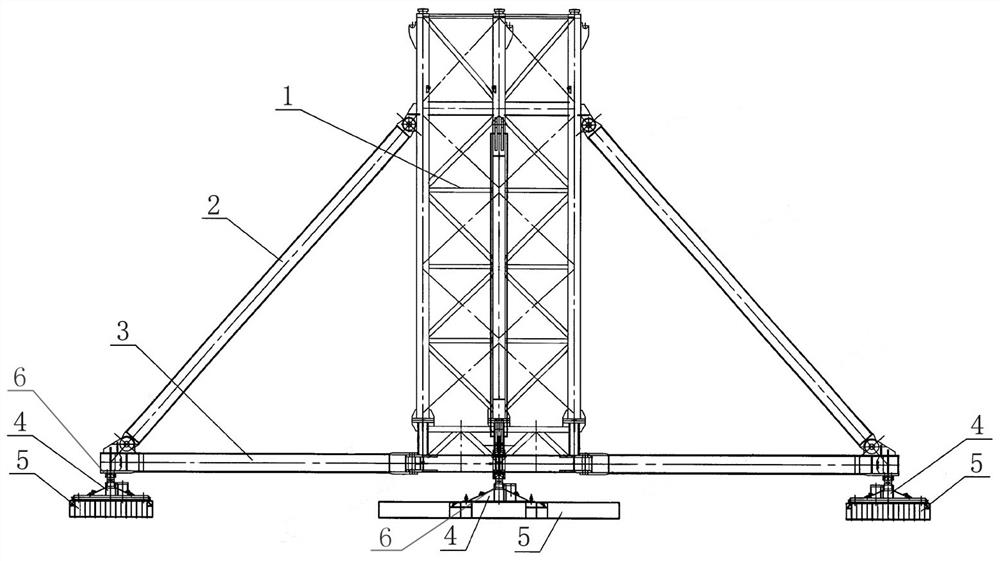

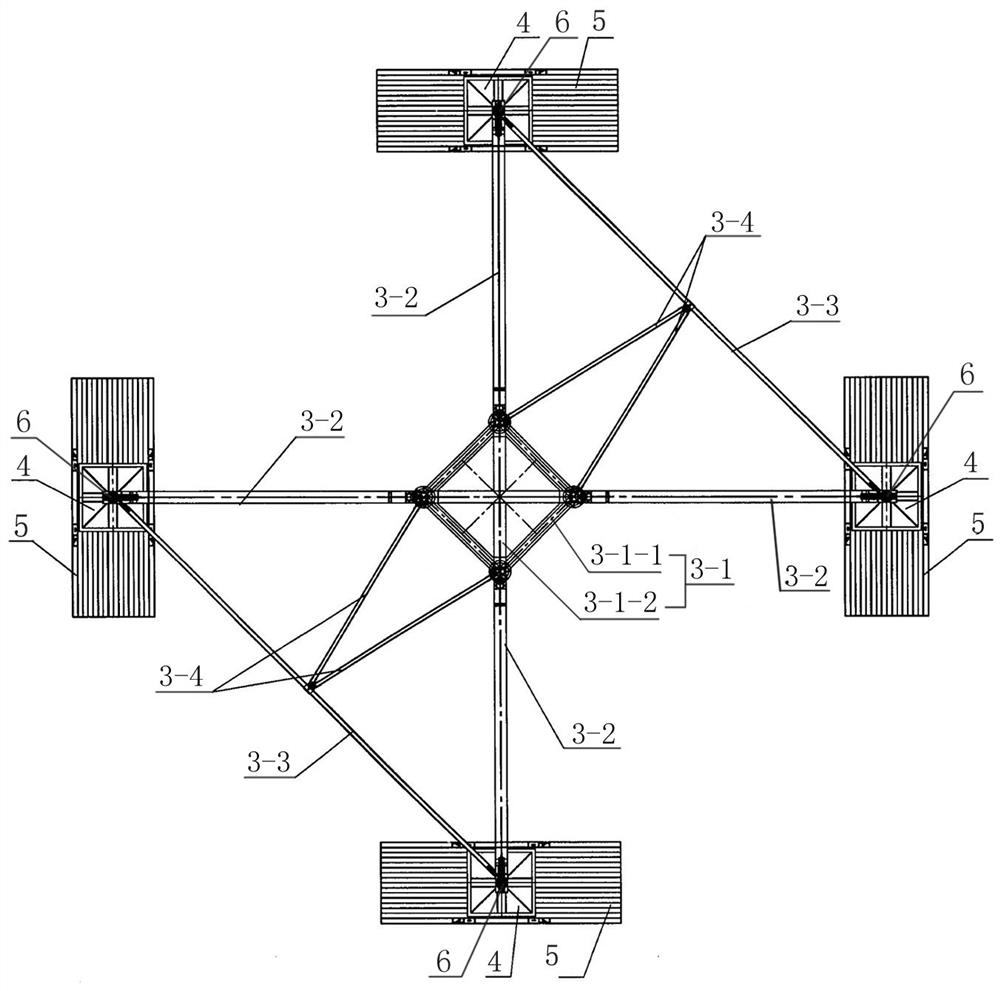

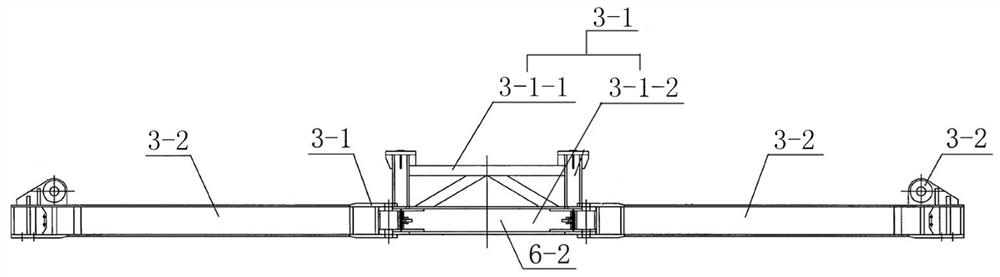

[0026]A wind power hoisting tower crane truss-type underframe suitable for all-terrain weak ground pressure and anti-tilt of the present invention includes a truss-type cross-shaped underframe 3 supported under the base section 1 of the tower bottom (the cross-shaped underframe 3 is a truss Type structure, as the installation foundation of the tower bottom foundation section 1, the support connects the tower bottom foundation section 1, the load on the upper part of the tower crane is transmitted to the cross-shaped underframe through the tower body chord, web part and oblique support 2, and bears pressure and tension) , and the two ends are respectively hinged on the upper part of the tower bottom foundation section and the top surface of the cross-shaped underframe. The four sets of supports 4 and the base distance wide surface outriggers 5 under the four most distal ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com