Low-cost hot-formed steel for pipe manufacturing and production and preparation method of low-cost hot-formed steel

A hot-formed steel, low-cost technology, applied in the field of steel rolling, can solve the problems of application and high alloy cost, and achieve the effect of reducing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

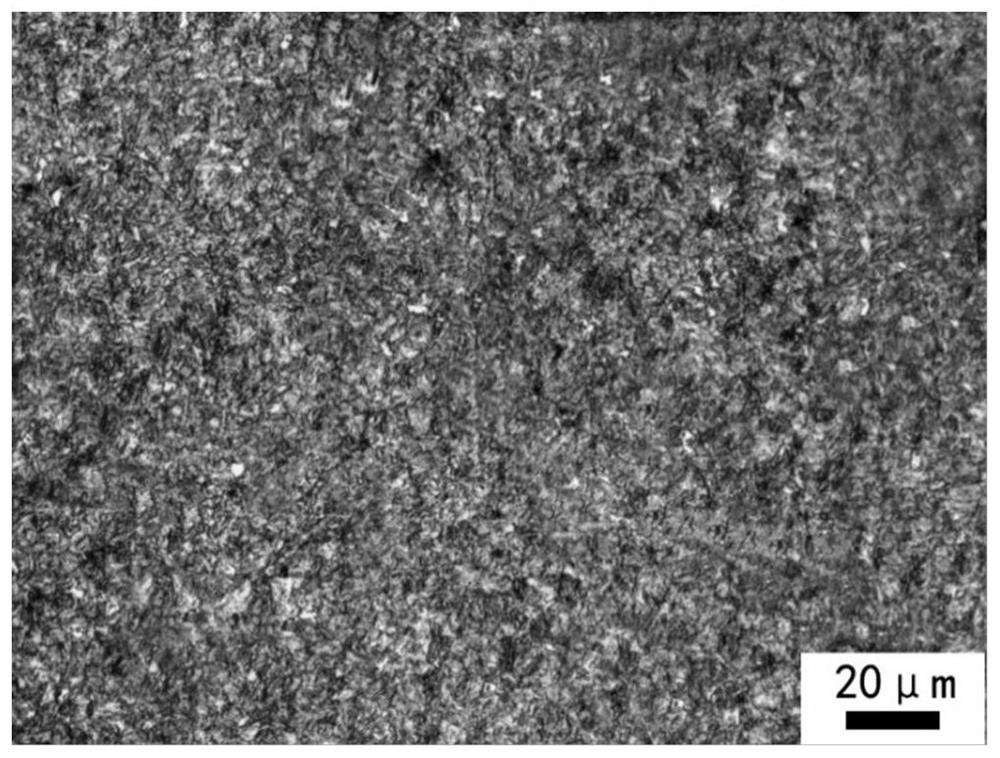

Image

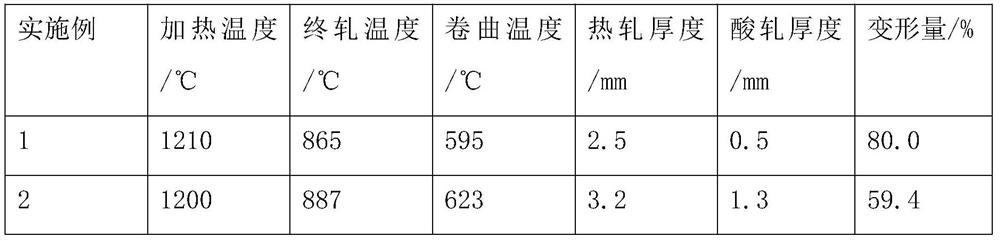

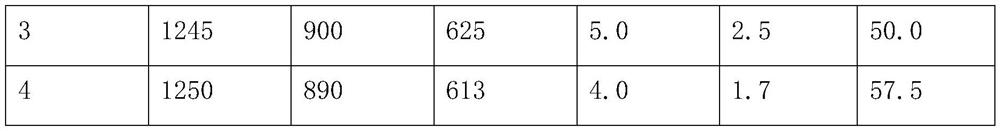

Examples

Embodiment Construction

[0020] The present invention provides a low-cost hot-formed steel for pipe making and a production and preparation method to produce a hot-formed steel with excellent performance at a low alloy cost, which can effectively reduce defects such as cracking and springback in the hot-forming process, and meet the needs of lightening the body weight. Demand for high-strength steel.

[0021] The technical solution in the embodiment of the present invention is to solve the above-mentioned technical problems, and the general idea is as follows: the hot-formed steel uses C-Si-Mn as the basic alloy system, and the specific element ratio and its main functions are detailed in the following description.

[0022] C:0.19%~0.28%;Si:0.20%~0.29%;Mn:1.5%~2.0%;P:≤0.015%;S:≤0.006%;Al:0.02%~0.06%;Ti:0.01%~0.03 %; N: ≤0.004%, the rest is Fe and unavoidable impurities.

[0023] C element is a solid solution strengthening element, which can effectively improve the strength of steel. If the C content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com