Cleaning device for textile machinery and using method of cleaning device

A technology for textile machinery and cleaning devices, which is applied in textiles, textiles, papermaking, knitting, etc., can solve the problems of large cleaning devices, rusty textile machinery, and low flexibility, and achieve a large cleaning range, prolong service life, and improve The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

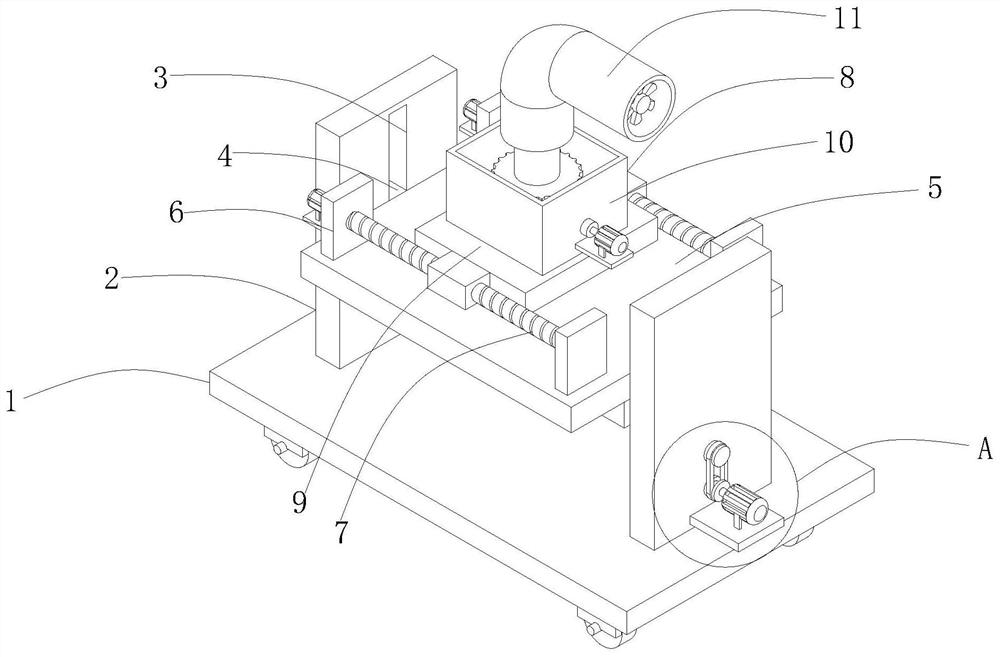

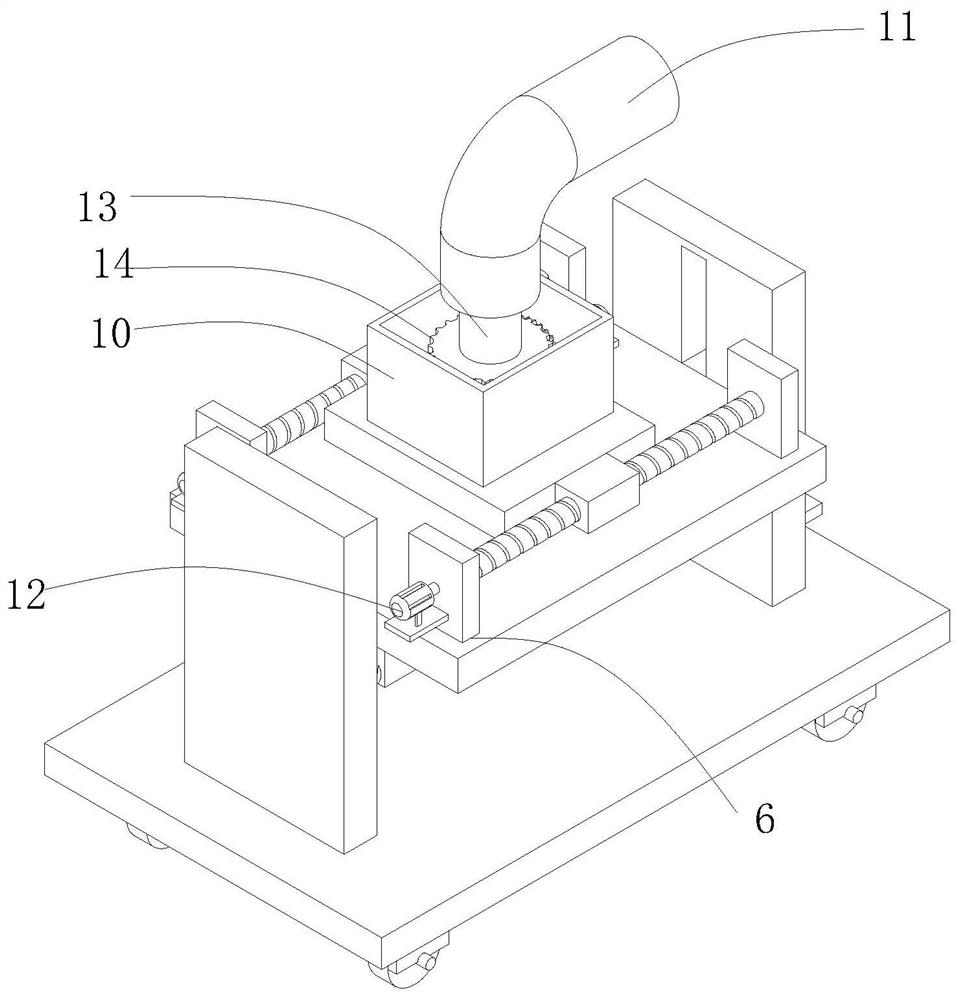

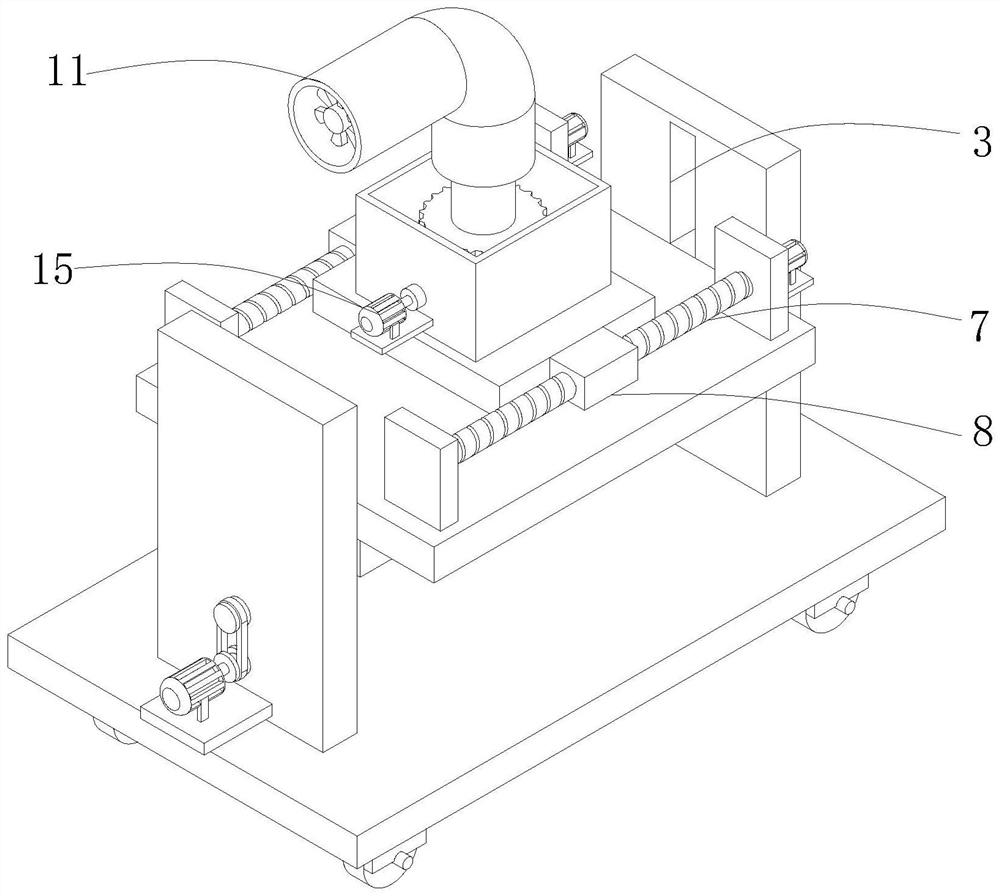

[0045] When using the present invention, first move the equipment to the corresponding position, fix its position by the brake block 22, connect the third motor 26 to the power supply, the third motor 26 drives the driving wheel 27 to rotate, and the driving wheel 27 drives The driven runner 28 is driven by the rotating belt 29 to rotate, so that the two-way threaded column 16 rotates. When the two-way threaded column 16 rotates, the second movable screw sleeve 17 moves laterally, driving the moving rod 18 to move longitudinally, and then drives the longitudinal movement of the moving block 19. Move, the moving block 19 drives the mounting frame plate 5, in the process, the air blower 11 is always in the repeated process of lifting, then the first motor 12 and the second motor 15 are connected to the power supply, and the first motor 12 drives the threaded rod 7 to rotate , so that the first movable screw sleeve 8 moves laterally, thereby causing the blower 11 to move laterally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com