Double-sleeve artesian deep well dewatering construction method and structure for muddy silty clay silty soil

A technology for silty clay and deep well dewatering, which is applied in the direction of cleaning method using gas flow, separation method, infrastructure engineering, etc., which can solve the problem that the stability of foundation pit slope is difficult to be guaranteed, easy to deposit in the pipe, and easy to pump out turbidity Water and other problems, to achieve good precipitation effect, single equipment, to ensure the effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to illustrate the embodiments of the present invention more clearly, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other accompanying drawings based on these drawings and obtain other implementations.

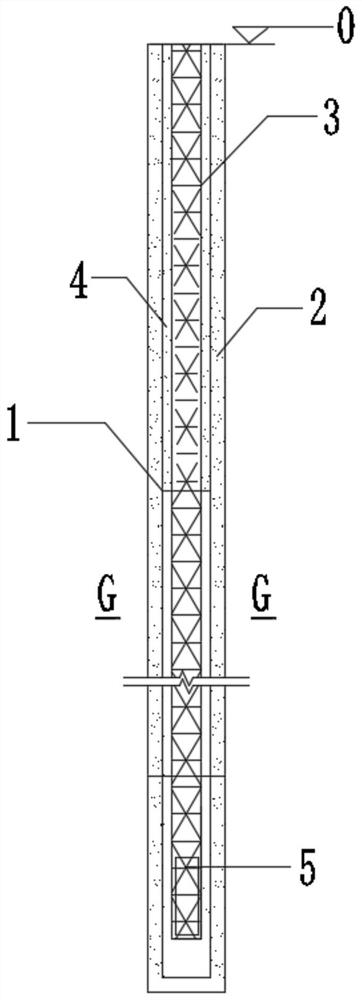

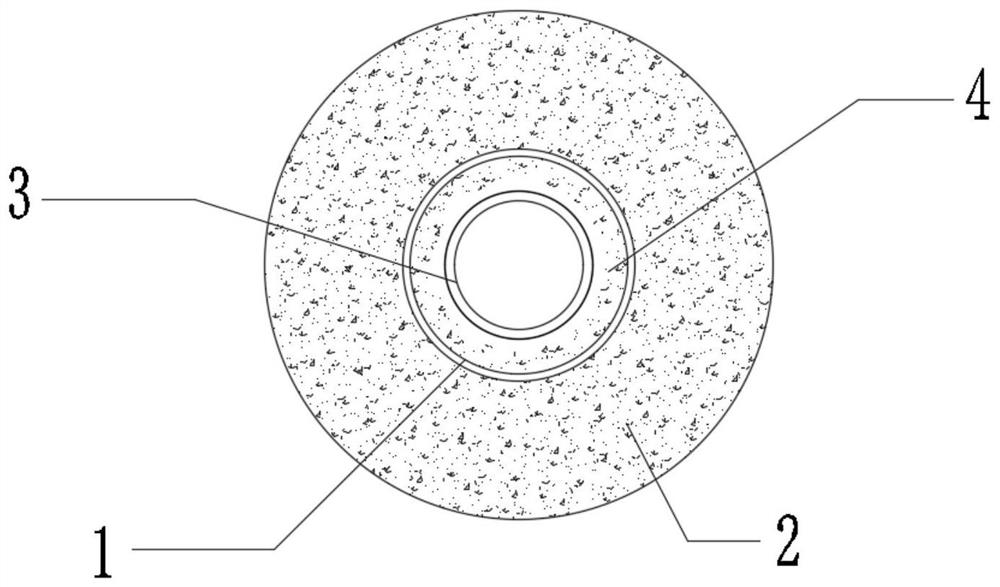

[0044] like figure 1 and 2 As shown, the double casing artesian deep well dewatering construction structure of the muddy silty clay sandwiched with silty soil in the embodiment of the present invention includes a coarse filter pipe 1, a coarse filter material 2, a fine filter tube 3, a fine filter material 4 and a high lift Submersible pump5.

[0045] Wherein, the coarse filter tube 1 is installed to the bottom of the hole formed in the deep well, and the nozzle is exposed to the preset target height on the ground; the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com