Duck feather drying device for poultry processing

A drying device and duck feather technology, which is applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of poor drying effect of duck feather and inability to obtain the drying effect of duck feather, so as to improve the breaking effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

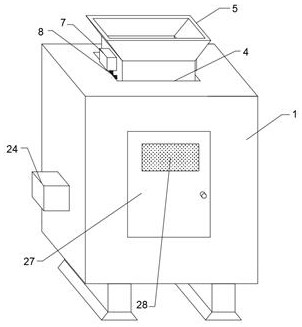

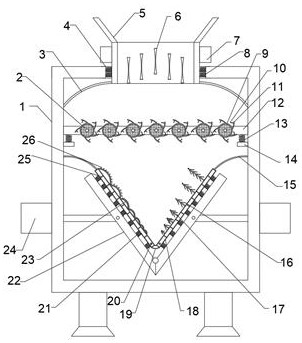

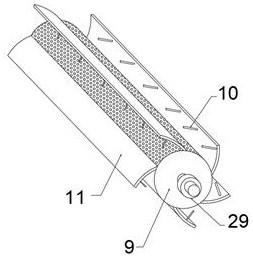

[0029] refer to Figure 1-4 , a duck feather drying device for poultry processing, comprising a box body 1, the four corners of the outer wall of the bottom of the box body 1 are fixedly connected with feet, the top of the box body 1 is fixedly connected with a feeding mechanism, and the bottom of the feeding mechanism is provided with a material guide mechanism , both ends of the bottom of the material guide mechanism are provided with a rotating plate 22, the rotating plate 22 is rotatably connected, and the end of the rotating plate 22 close to the box body 1 is rotatably connected to a cylinder 24, the cylinder 24 is fixedly connected to the outer wall of the box body 1, and the two ends of the rotating plate 22 The outer wall of the room is fixedly connected with a plurality of third springs 21, the other end of the third spring 21 is fixedly connected with a binder plate 18, the binder plate 18 is set to be hollow, and the inner wall of the binder plate 18 is fixedly conn...

Embodiment 2

[0038] refer to figure 1 and Figure 3-5 , a duck feather drying device for poultry processing, a lamp holder 30 is arranged at the bottom of the material retaining soft cloth 3, an infrared lamp 31 is fixedly connected to the bottom of the lamp holder 30, the infrared lamp 31 is electrically connected to an electric control box, and the infrared lamp 31 is two Each end is provided with a reflector 32, and the emitter 32 is set as an irregular broken line. The bottom of the infrared lamp 31 is provided with a lampshade 33, and the lampshade 33 and the reflector 32 are fixedly connected.

[0039] During use, the infrared lamp 31 on the lamp holder 30 on the top of the material guide mechanism is controlled by an electric control box to generate infrared rays, thereby pre-drying the duck feathers passing through the material guide mechanism, and improving the drying effect of the device on the duck feathers , by arranging the reflectors 32 at both ends of the infrared lamp 31 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com