Diesel engine box body simulation test bench system for simulating altitude climate of plateau and test method thereof

A bench system and simulation test technology, applied in the direction of internal combustion engine testing, engine testing, machine/structural component testing, etc., can solve problems such as high cost, inability to conduct tests in other regions, and equipment that cannot be moved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

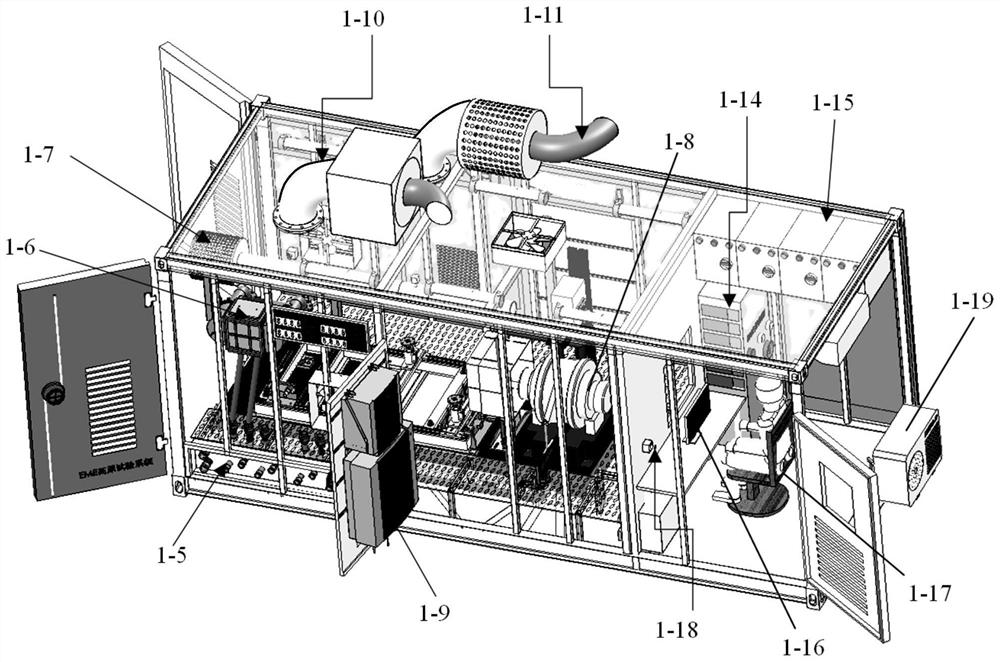

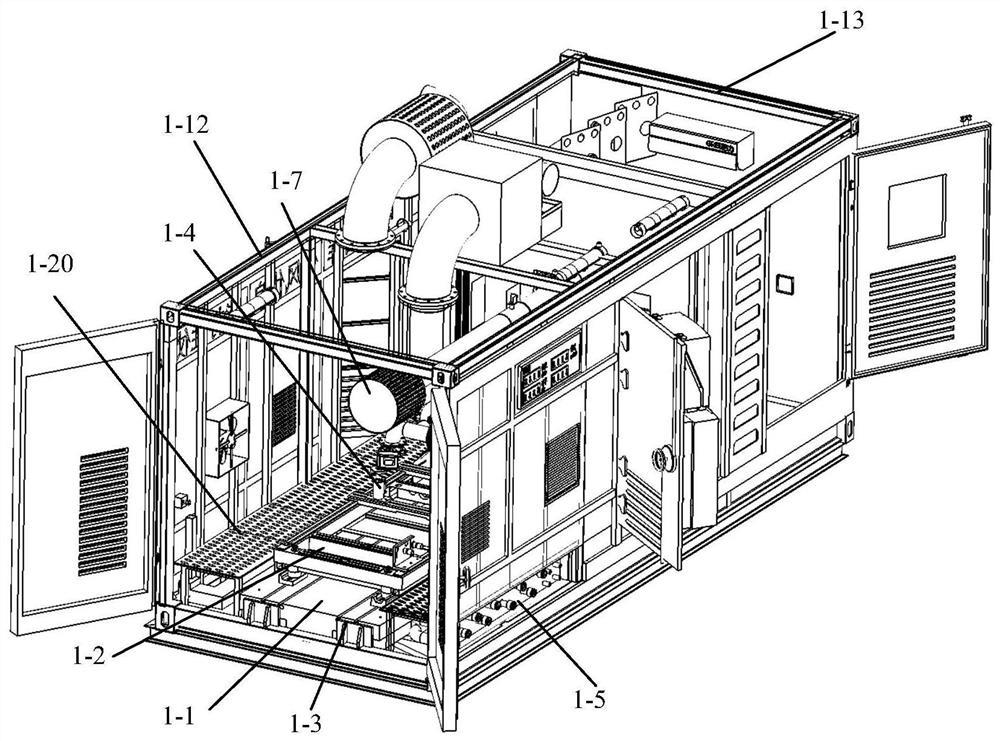

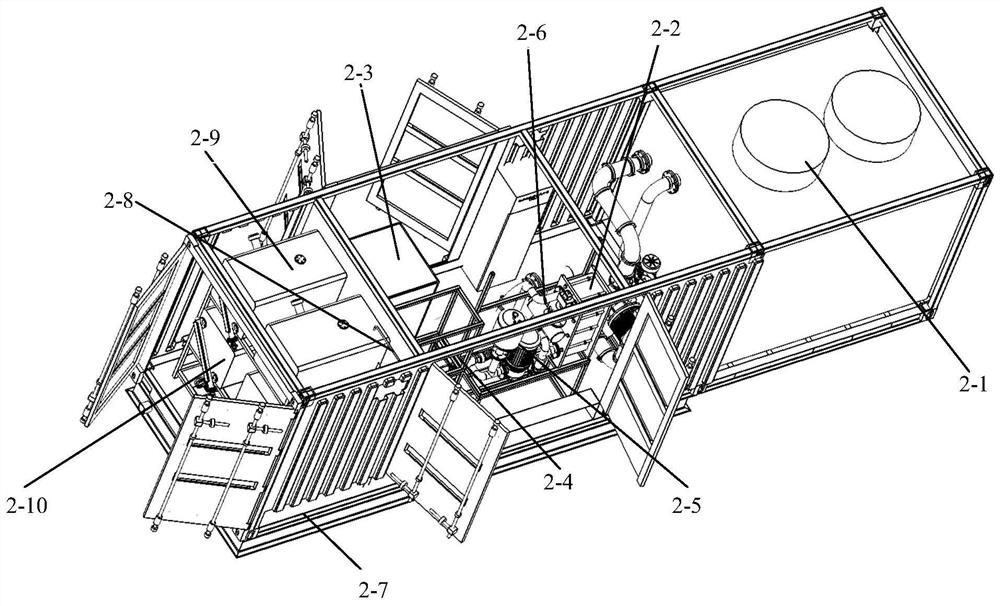

[0023] Please refer to Figure 1 ~ Figure 3 , a diesel engine box simulation test bench system for simulating plateau altitude climate, including a test box 1, an energy box 2 and a diesel generator set 3;

[0024] The test box 1 includes a test box assembly and a monitoring box assembly; the test box assembly includes a test box body 1-12, an iron floor 1-1 is laid on the bottom of the test box body 1-1, and a fast Loading trolley 1-2 (the quick-loading trolley is an existing device, the specific structure can refer to the structure of the quick-docking trolley in the patent material of application number 2009200842748), the air spring shock absorber 1-3 is set under the iron floor 1-1, and the quick-loading trolley 1-2 is provided with engine adjustable support legs 1-4, and the lower side of the iron floor 1-1 is provided with an oil-water-gas docking layer 1-5 ( Figure 4 Among them, a, b, and c represent the oil supply pipeline, air supply pipeline and water supply pipel...

Embodiment 2

[0028] The difference from Embodiment 1 is that an air conditioner 1-19 is provided outside the monitoring box assembly for the staff to be comfortable. In addition, mufflers are provided on the intake pipe 1-10 and the exhaust pipe 1-11. ; The internal side walls of the monitoring box 1-13 are made of sound-absorbing materials.

[0029] The top cover of the monitoring box body 1-13 is a transparent top cover made of transparent materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com