A detection method and detection equipment for an audio chip

An audio chip and detection method technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of low strength, easy bending, wrong performance parameters of testing equipment, etc. The effect of improving capacity and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

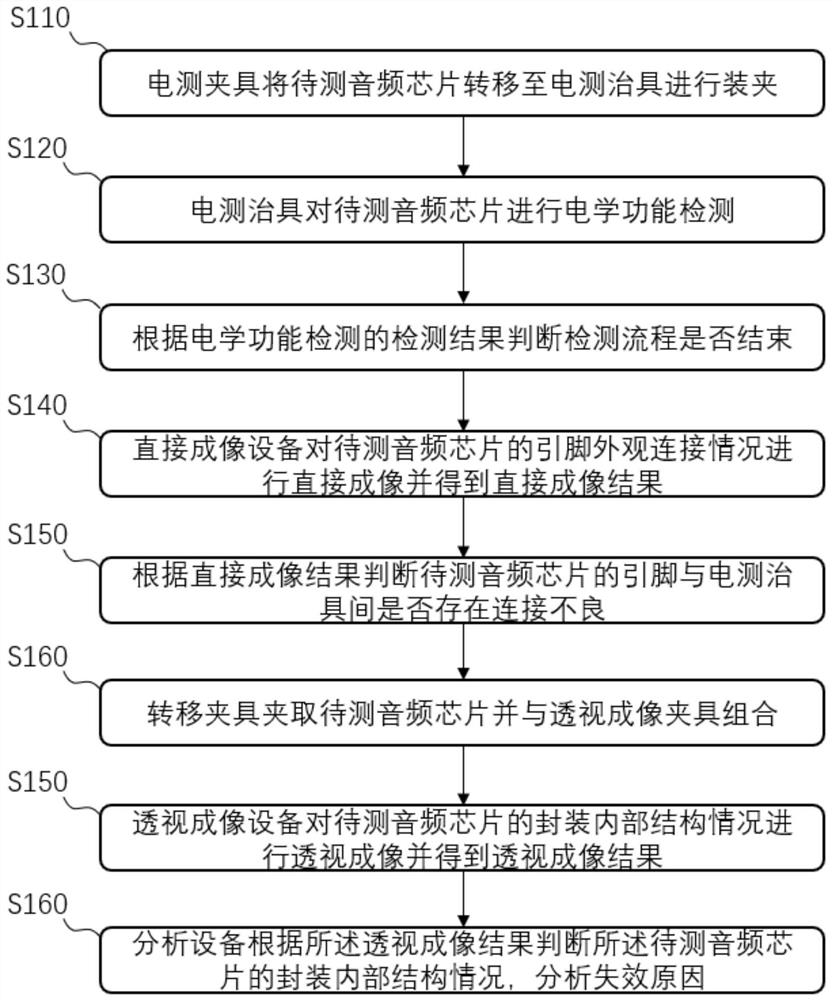

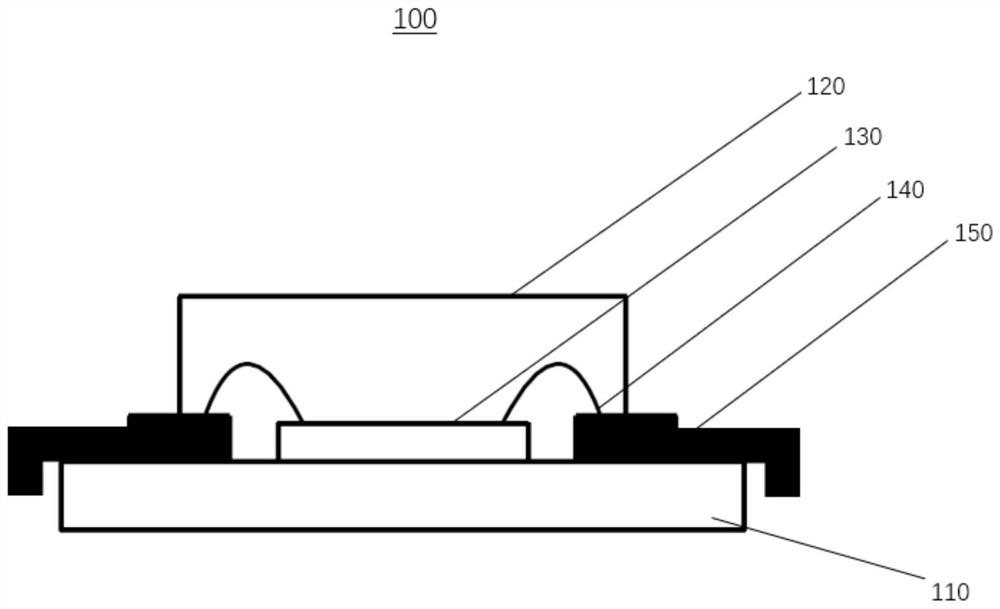

[0039] see figure 1 , image 3 as well as Figure 4 ,in, figure 1 It is a schematic flowchart of the detection method of the audio chip according to the embodiment of the present invention; image 3 It is a schematic diagram of the internal structure of the audio chip package; Figure 4 It is a schematic diagram of the integrated circuit structure inside the audio chip package.

[0040] This embodiment provides an audio chip detection method, which is used for electrical function detection and failure cause analysis of the audio chip 100 to be tested, including:

[0041] Clamping step 1 S110: the audio chip 100 to be tested is transferred to the electric measurement fixture 220 by the electrical measuring fixture 210 for clamping;

[0042] Step S120 of electrical measurement: The electrical measurement fixture 220 performs electrical function detection on the audio chip 100 to be tested to determine whether the electrical function of the audio chip 100 to be tested is qua...

Embodiment 2

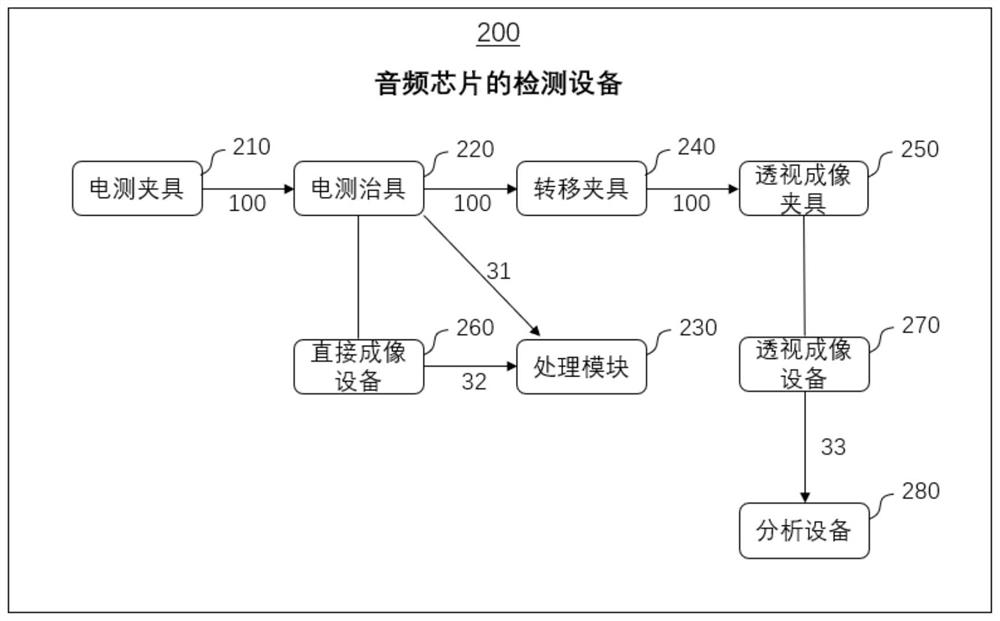

[0058] see figure 2 ,in, figure 2 It is a schematic structural diagram of a detection device for an audio chip according to an embodiment of the present invention.

[0059] This embodiment provides an audio chip detection device 200, which is used to implement the above-mentioned audio chip detection method, which specifically includes:

[0060] The electrical measuring fixture 210 is used to transfer the audio chip 100 to be tested to the electrical measuring fixture 220; the electrical measuring fixture 220 is used to clamp the audio chip 100 to be tested and perform electrical functions on the audio chip 100 to be tested Detection, to determine whether the electrical function of the audio chip 100 to be tested is qualified; the processing module 230 is used to judge whether the detection process is over according to the detection result 31 of the electrical function detection, if the detection result 31 of the electrical function detection is qualified , then it is judg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com