Semiconductor substrate photoresist layer defect detection system based on AI and cloud computing technology

A photoresist layer and defect detection technology, which is applied in the direction of manufacturing computing systems, computing, computer components, etc., can solve the problems of poor real-time performance, poor detection effect, and low accuracy, so as to solve the problems of low manual detection efficiency and improve accuracy sex, efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings.

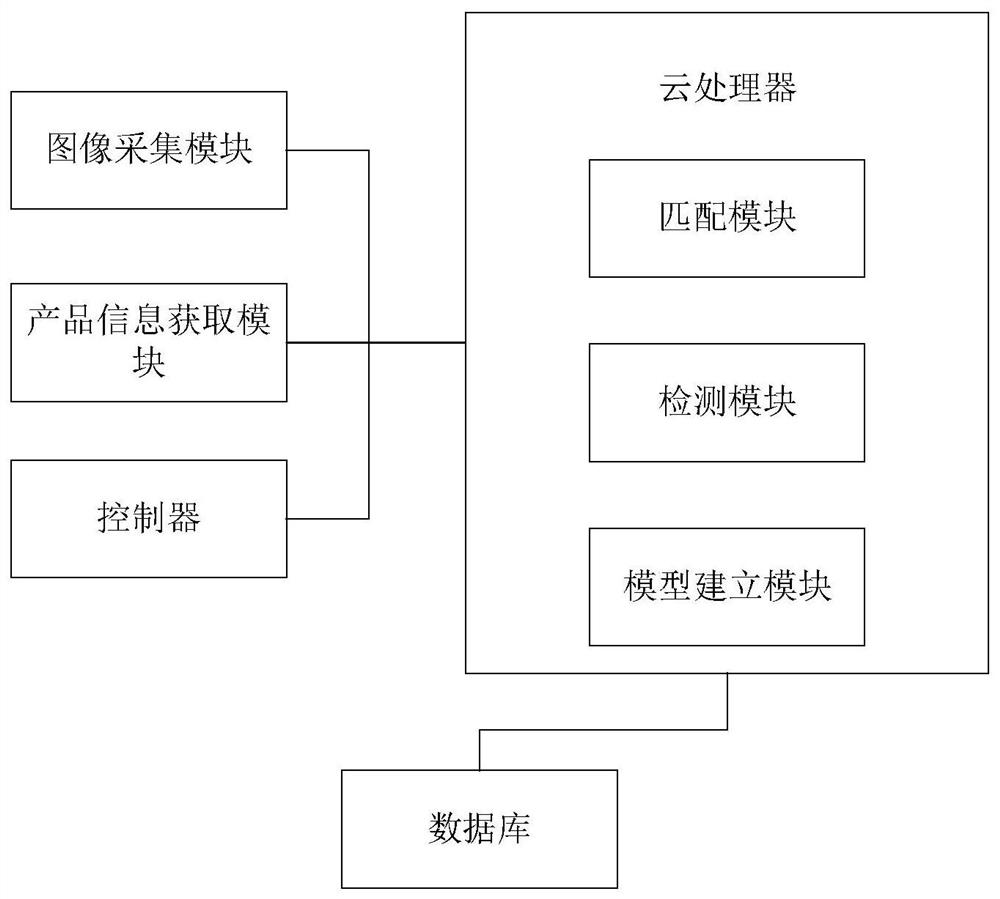

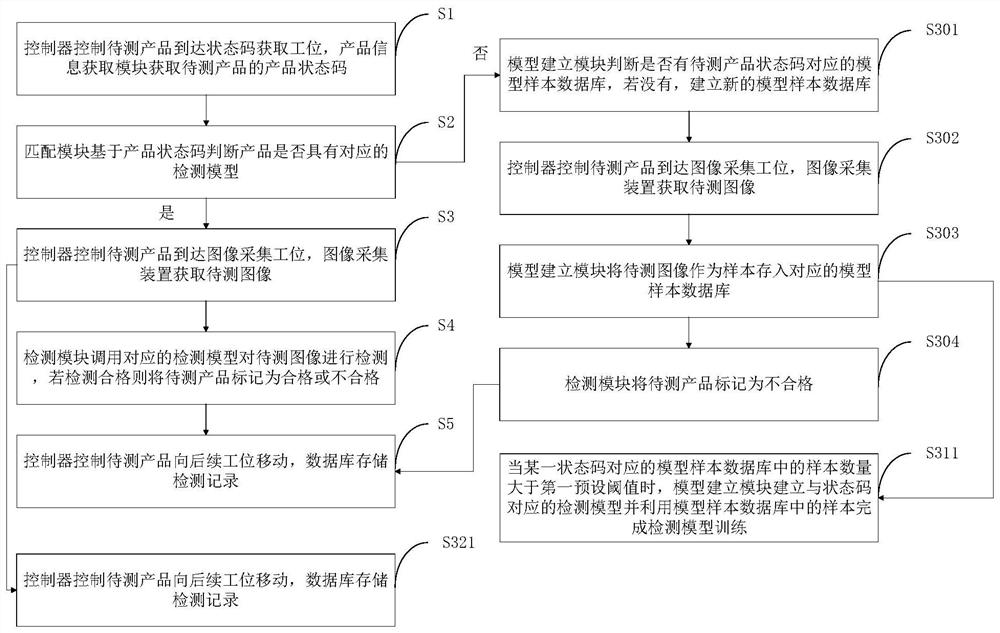

[0031] Such as figure 1 As shown, it is a schematic diagram of a semiconductor substrate photoresist layer defect detection system based on AI and cloud computing technology disclosed by the present invention, including a product information acquisition module, an image acquisition module, a cloud processor, a database, and a controller connected to each other through communication, The cloud processor includes a matching module and a detection module; such as figure 2 As shown, the AI and cloud computing technology semiconductor substrate photoresist layer defect detection system includes the following steps when detecting:

[0032] S1. The controller controls the product to be tested to arrive at the status code acquisition station, and the product information acquisition module acquires the product status code of the product to be tested;

[0033] S2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com