Lightning protection post insulator and manufacturing method thereof

A pillar insulator and the technology of its manufacturing method, which are applied in the field of surge arresters, can solve the problems of poor protection of insulators and transmission lines, poor lightning protection effect, etc., and achieve the effects of improving lightning protection effect, easy processing, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

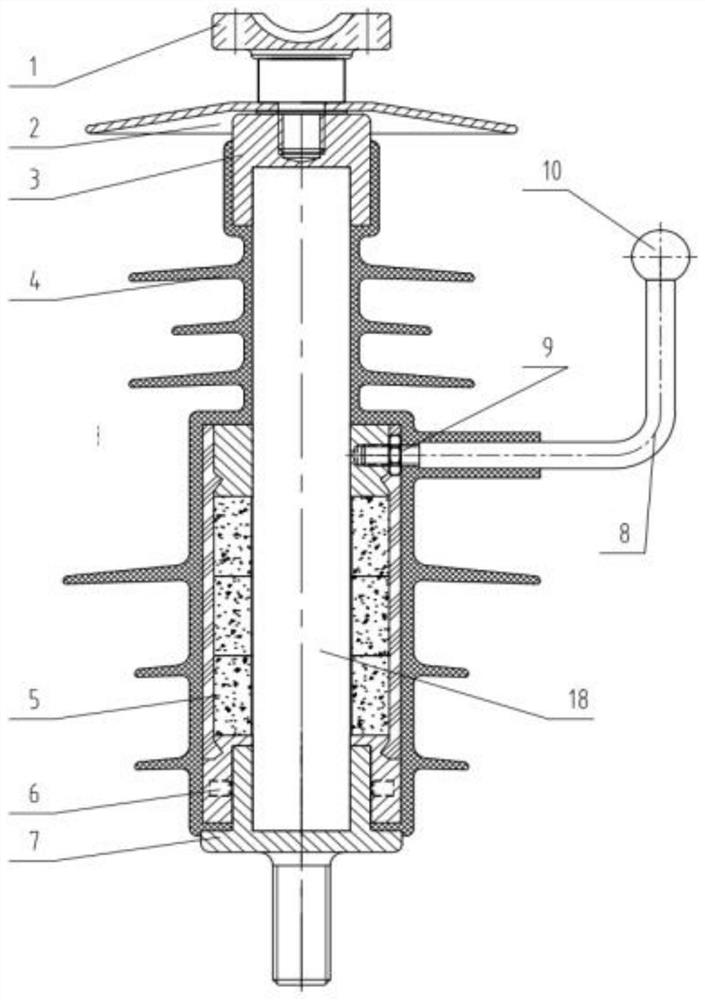

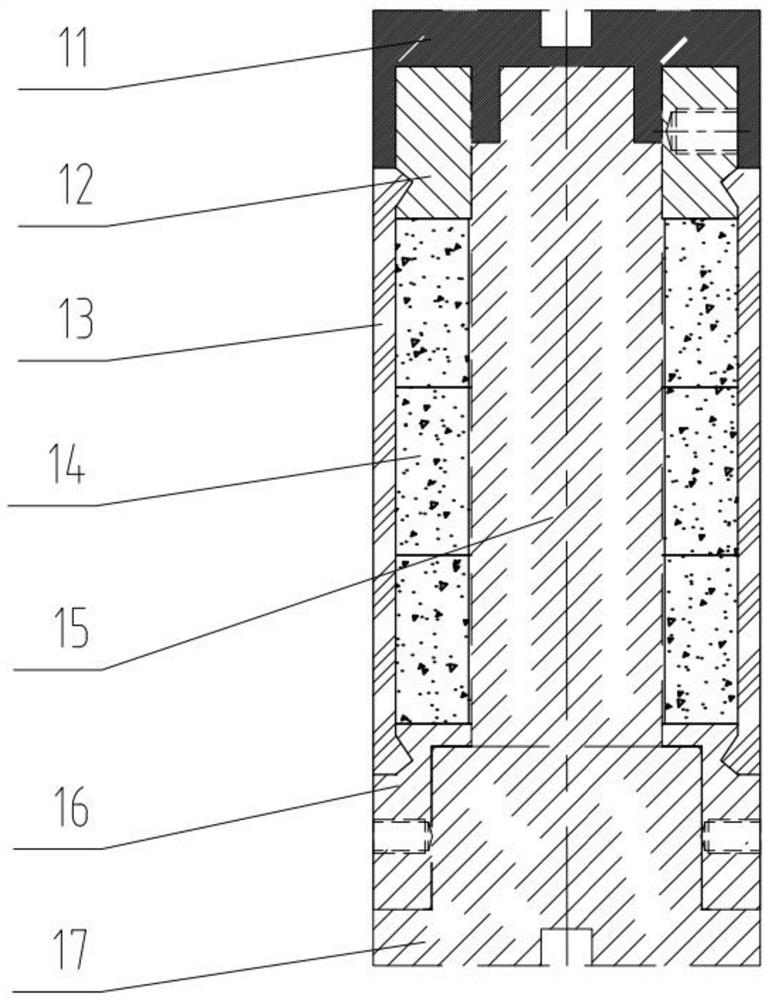

[0034] A lightning protection post insulator, such as figure 1 with figure 2 As shown, it includes the drawing rod 18, the lower fitting 7 located at the bottom of the drawing rod 18 and connected to the cross arm, and the upper fitting at the top of the drawing rod 18; the drawing rod 18 and the lower fitting 7 are provided with lightning protection The winding core 5; the lightning protection winding core 5 includes a high-gradient zinc oxide resistance sheet 14 and an aluminum alloy electrode, and the aluminum alloy electrode includes an upper electrode 12 and a lower electrode 16 respectively arranged at both ends of the high-gradient zinc oxide resistance sheet 14; the lower electrode 16 and the lower fitting 7 are fixed by threaded top screw 6;

[0035] The lightning protection winding core 5 is connected with a discharge connecting rod 8 of L-shaped structure, the vertical end of the discharge connecting rod 8 and the drawing rod 18 is threadedly connected with the up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com