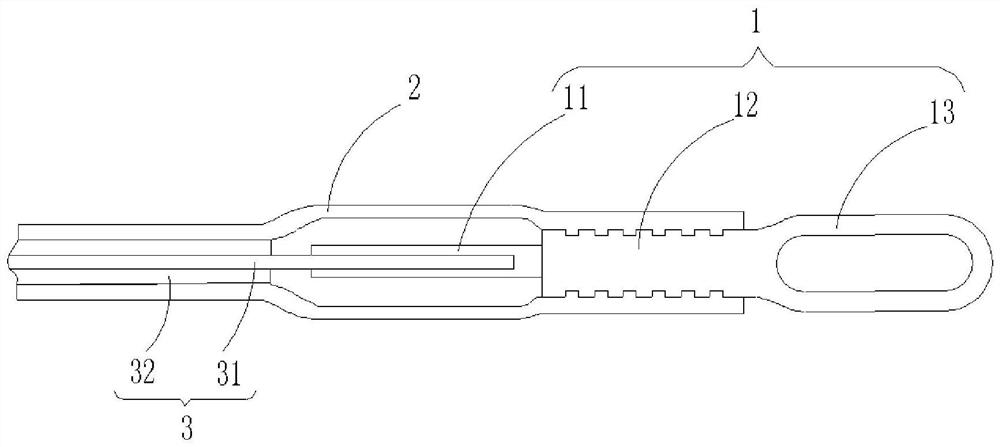

A device for measuring and controlling the crimping position of an aluminum crimping tube of a transmission line

A technology of crimping position and power transmission line, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problems of overvoltage, easy heat generation and leakage pressure of the connection part and wire, so as to avoid leakage or overvoltage. , to ensure the connection strength, the effect of ensuring the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

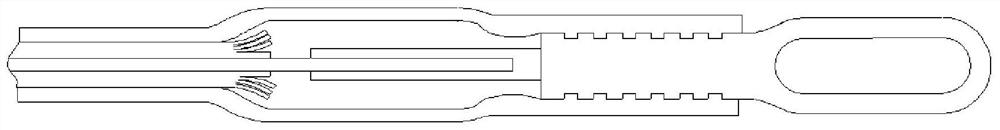

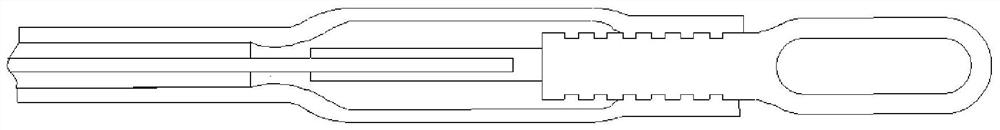

[0034] see Figure 4 , Figure 5 and Image 6 As shown, the present invention provides a device for measuring and controlling the crimping position of an aluminum crimping tube of a power transmission line, including a first clamping plate 5, wherein the first clamping plate 5 includes a clamping plate and a limit plate, and the limit plate is vertically fixed on the the clamping plate. The first clamping plate 5 is in an "L" shape, and one end of the clamping plate is connected to the ruler 4 in the "L" shape. In the specific implementation process, the main body of the ruler 4 is parallel to the clamping plate, so the The main body of the ruler 4 is provided with a length scale along the length direction, and the main body of the ruler 4 is distributed along the length direction with a T-shaped chute 41, and the sliding groove 41 is slidably connected with a T-shaped slider 42. Steel arms 43 are respectively fixed on both sides of the sliding block 42 . The opposite side...

Embodiment 2

[0040] see Figure 7 As shown, the difference between Embodiment 2 and Embodiment 1 is that two sliding blocks 42 are slidably connected to the scale 4, and steel arms 43 are respectively fixed at both ends of the two sliding blocks 42, and one steel arm 43 is used to record the end position of the connecting part 12 , and the other steel arm 43 is used to record the end position of the wire 3 .

Embodiment 3

[0042] see Figure 7 and Figure 8 As shown, another apparatus for measuring and controlling the crimping position of the aluminum crimping pipe of a power transmission line is provided. Compared with the second embodiment, the third embodiment improves the clamping of the steel anchor hanging ring 13 . Specifically, it includes a first clamping plate 5, the first clamping plate 5 is fixed to a fixing column 81, the fixing column 81 is fixed to a base 8, and a cylinder 82 is fixedly arranged on the base 8 relative to the fixing column 81, and the The second clamp plate 6 is connected to the air cylinder 82, the air cylinder 82 is connected to the air source through a two-position three-way valve, and the cylinder 82 is controlled to drive the second clamp plate 6 to move through the two-position three-way valve, so that all the The second clamping plate 6 and the first clamping plate 5 clamp the steel anchor hanging ring 13 .

[0043] The scale 4 is fixed on the first splint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com