Cake blank forming and slitting machine for food processing and forming and slitting method thereof

A technology for food processing and cake embryos, applied in dough forming and cutting equipment, applications, food science, etc., can solve problems such as poor cutting effect, low forming quality, and difficult tool cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

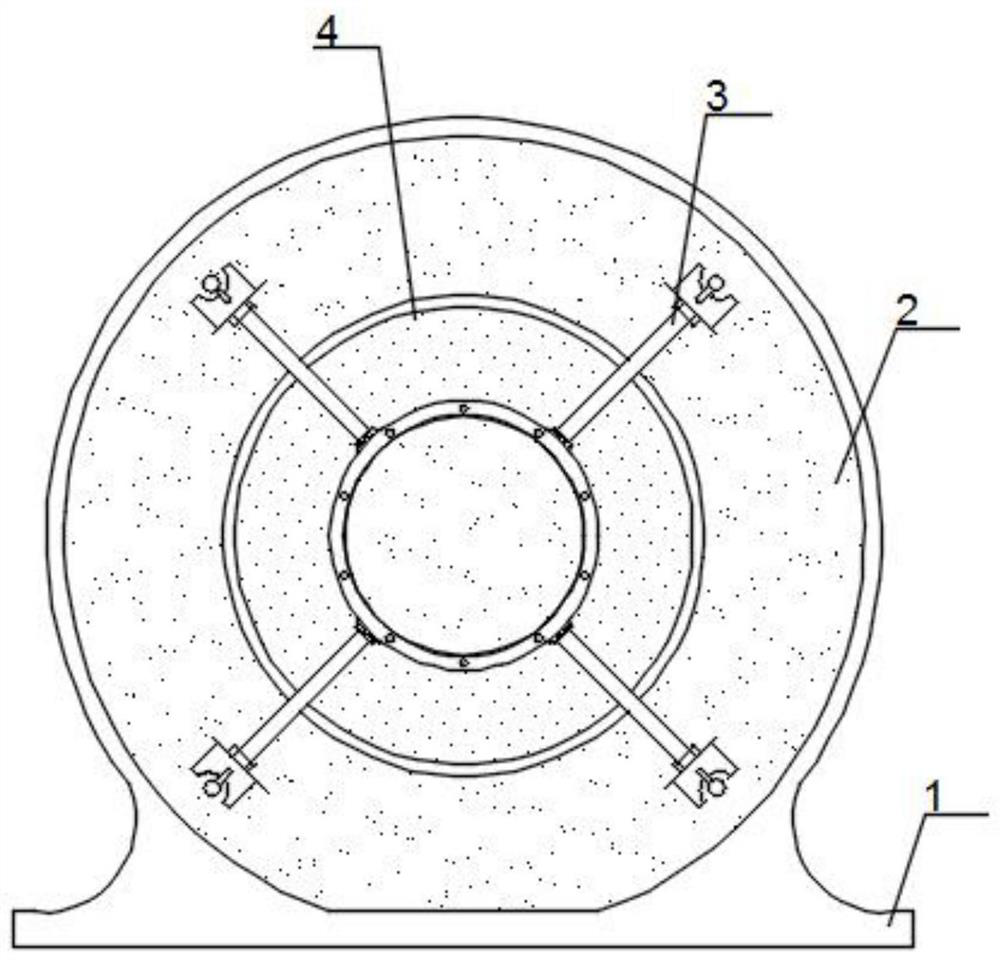

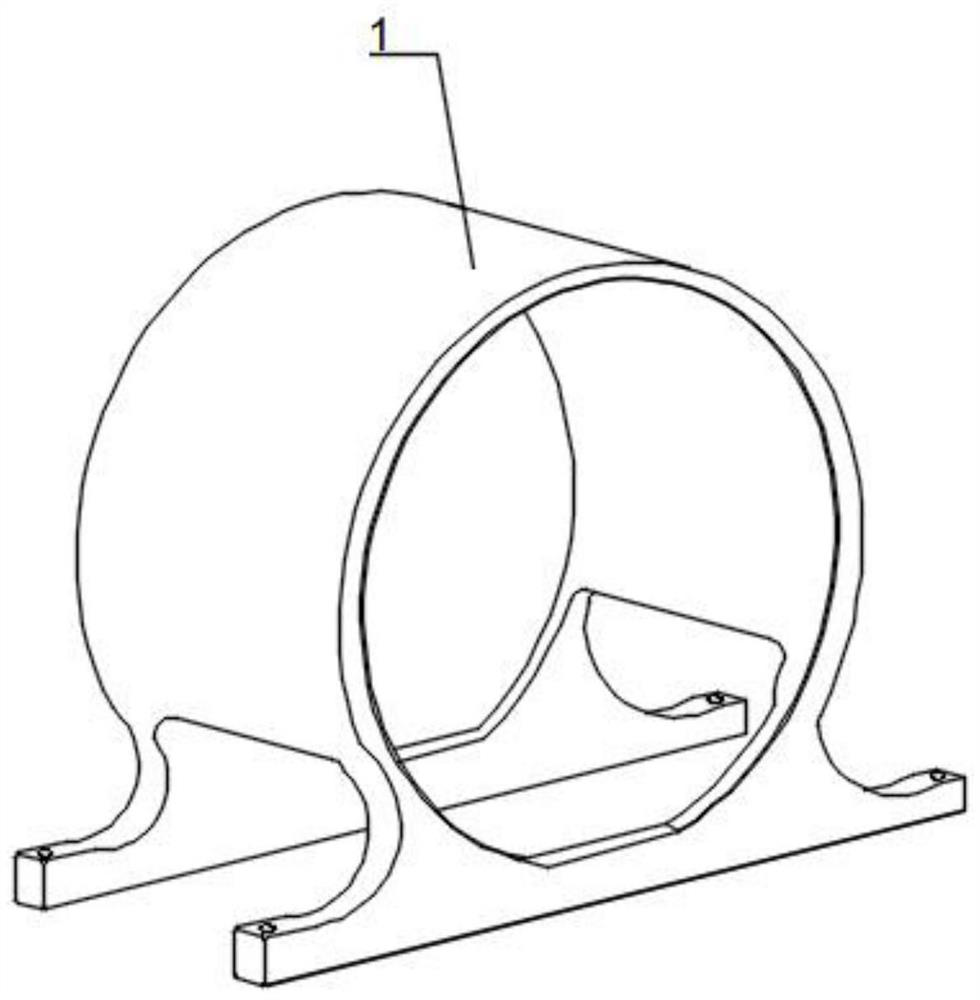

[0031] Such as Figure 1-3 As shown, the cake embryo forming and cutting machine for food processing includes a bearing frame 1 and a window 2, the window 2 is fixed at the front and rear ports of the bearing frame 1, and a drive unit 4 is arranged on the rear side of the bearing frame 1; There is a forming and cutting component 3, and the driving unit 4 is connected to the forming and cutting component 3 through the perspective window 2;

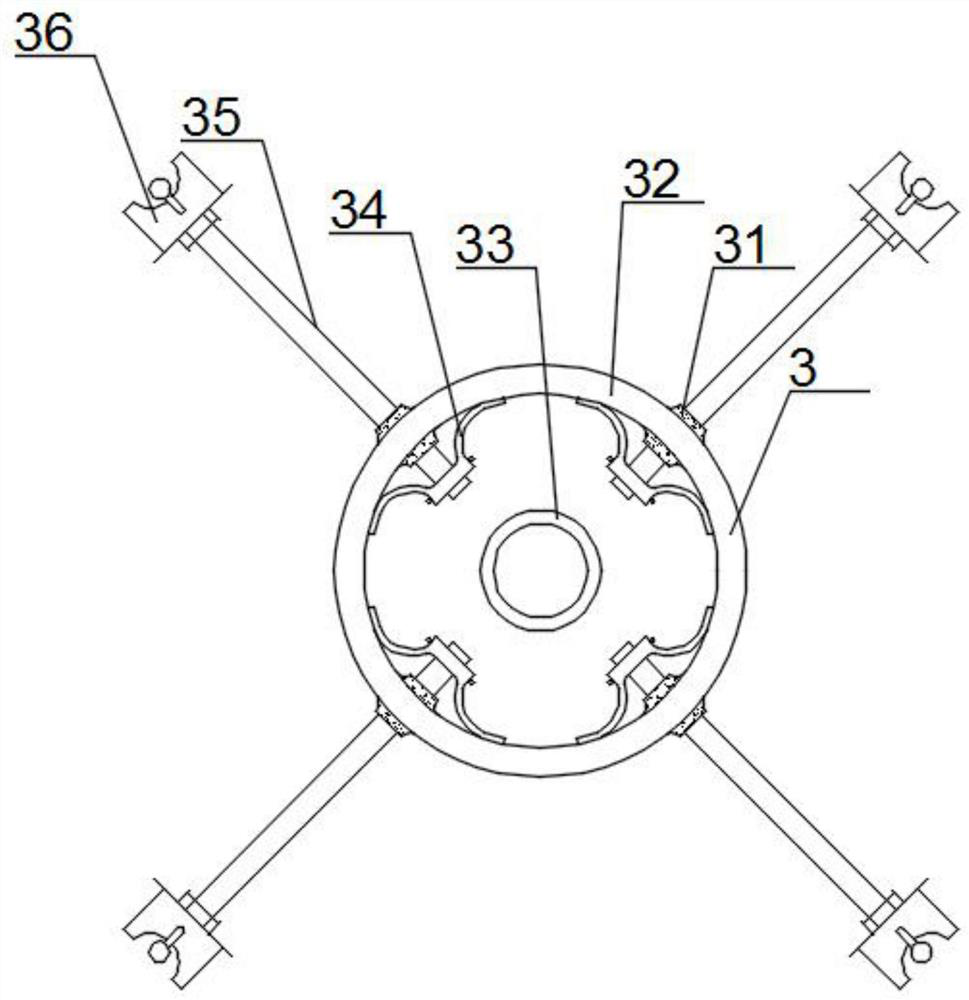

[0032] The forming and cutting assembly 3 includes a ring sleeve 32, which is provided in the bearing frame 1. The rear end of the ring sleeve 32 is a dense end, and the front end of the ring sleeve 32 is sealed and embedded with a plug disc; the surface of the ring sleeve 32 is equally divided into rings. There are four inserting plates 35, a sealing sleeve 31 is provided at the tangent between the inserting plate 35 and the ring sleeve 32, and the sealing sleeve 31 is embedded in the gap between the inserting plate 35 and the ring sleeve ...

Embodiment 2

[0035] Such as Figure 1-5As shown in the pie forming and cutting machine for food processing, the air cutting head 36 includes a tapered passage 361, a valve adjustment assembly 362 and a cutting head 363. A tapered passage 361 is provided, and the tapered passage 361 is connected to the inner cavity of the inserting plate 35; a valve adjustment assembly 362 is arranged in the tapered passage 361, and the valve adjustment assembly 362 is hooked to the wall of the cutting head 363; wherein The valve adjustment assembly 362 includes a partition 3621, a connecting pipe 3622, an L-shaped rod 3623 and a counterweight ball 3624. A connecting pipe 3622 is longitudinally arranged in the tapered passage 361, and the upper and lower ends of the connecting pipe 3622 are fixedly connected with a partition 3621; The front and rear ends of 3622 are provided with L-shaped rods 3623. The L-shaped rods 3623 are divided into short rods and long rods. The short rods run through the cutting head...

Embodiment 3

[0039] Such as figure 1 , 3 , 6 and 7, the cake embryo forming and cutting machine used for food processing, the inner side of the ring sleeve 32 is provided with a sleeve 342, the two ends of the sleeve 342 are fixed with feet 341, and the feet 341 are fixed to the inner wall of the ring sleeve 32; The box 342 is interspersed with a plugboard 35, and the two sides of the plugboard 35 are symmetrically provided with a clamping structure 343 in the sleeve box 342; the clamping structure 343 is clamped to the side wall of the plugboard 35; wherein the clamping structure 343 includes a sphere 3431, Pull rod 3432, elastic friction plate 3433 and socket 3434, the two sides of insert plate 35 are symmetrically provided with elastic friction plate 3433 in sleeve box 342, one side of elastic friction plate 3433 is fixed with socket 3434 at the inner wall of sleeve box 342; elastic friction The sheet 3433 is plugged and fixed into the socket 3434, and the vertical position of the elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com