Salad dressing capable of melted into oil after baking and capable of industrial production

A technology of oil salad, soybean oil, applied in the direction of food ingredients, food ingredients as antioxidants, food science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The invention provides a technical solution: an industrially produced salad dressing that can be turned into oil after baking, which is prepared from the following components by mass: soybean oil 69.619%, water 12.0%, whole egg liquid 3.0%, white sugar 4.0%, Vinegar 9.5%, Xanthan Gum 0.04%, Salt 1.8%, Disodium EDTA 0.001%, and Antioxidant 0.04%.

[0028] The salt in the above-mentioned salad dressing ingredients is iodized salt.

[0029] The antioxidant in the above-mentioned salad dressing ingredients adopts disodium edetate.

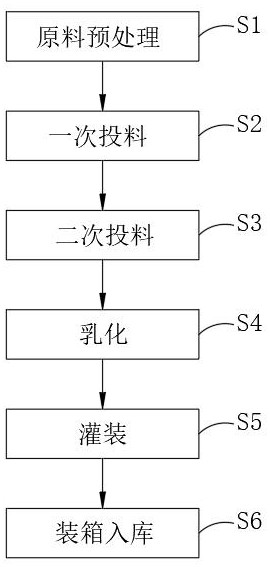

[0030] In addition, the present invention also provides a method for preparing salad dressing that can be converted into oil after baking, which can be industrially produced, comprising the following steps:

[0031] S1. Raw material pretreatment: each raw material is sorted, screened, cleaned and dried in sequence, and according to the proportion, the raw materials that have undergone the above pretreatment operations are weighed and placed in ...

Embodiment 2

[0038] The invention provides a technical proposal: an industrially produced salad dressing that can be turned into oil after baking, which is prepared from the following components by mass: soybean oil 66.9305%, water 16.0%, whole egg liquid 6.0%, white sugar 2.0%, Vinegar 7.0%, Xanthan Gum 0.01%, Salt 2.0%, Disodium EDTA 0.0095%, and Antioxidant 0.05%.

[0039] The salt in the above-mentioned salad dressing ingredients is iodized salt.

[0040] The antioxidant in the above-mentioned salad dressing ingredients adopts disodium edetate.

[0041] In addition, the present invention also provides a method for preparing salad dressing that can be converted into oil after baking, which can be industrially produced, comprising the following steps:

[0042] S1. Raw material pretreatment: each raw material is sorted, screened, cleaned and dried in sequence, and according to the proportion, the raw materials that have undergone the above pretreatment operations are weighed and placed i...

Embodiment 3

[0049] The invention provides a technical proposal: an industrially produced salad dressing that can be turned into oil after baking, which is prepared from the following components by mass: soybean oil 70.949%, water 15.0%, whole egg liquid 5.0%, white sugar 2.5%, Vinegar 5.0%, Xanthan Gum 0.04%, Salt 1.5%, Disodium EDTA 0.001%, and Antioxidant 0.01%.

[0050] The salt in the above-mentioned salad dressing ingredients is iodized salt.

[0051] The antioxidant in the above-mentioned salad dressing ingredients adopts disodium edetate.

[0052] In addition, the present invention also provides a method for preparing salad dressing that can be converted into oil after baking, which can be industrially produced, comprising the following steps:

[0053] S1. Raw material pretreatment: each raw material is sorted, screened, cleaned and dried in sequence, and according to the proportion, the raw materials that have undergone the above pretreatment operations are weighed and placed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com