Spoke type motorcycle wheel and motorcycle

A motorcycle and spoke technology, applied in spoked wheels, wheels, rims, etc., can solve the problems of weakened structural strength, high cost, poor impact resistance, etc., and achieve good elastic deformation space, reduce accident rates, and reduce tire noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

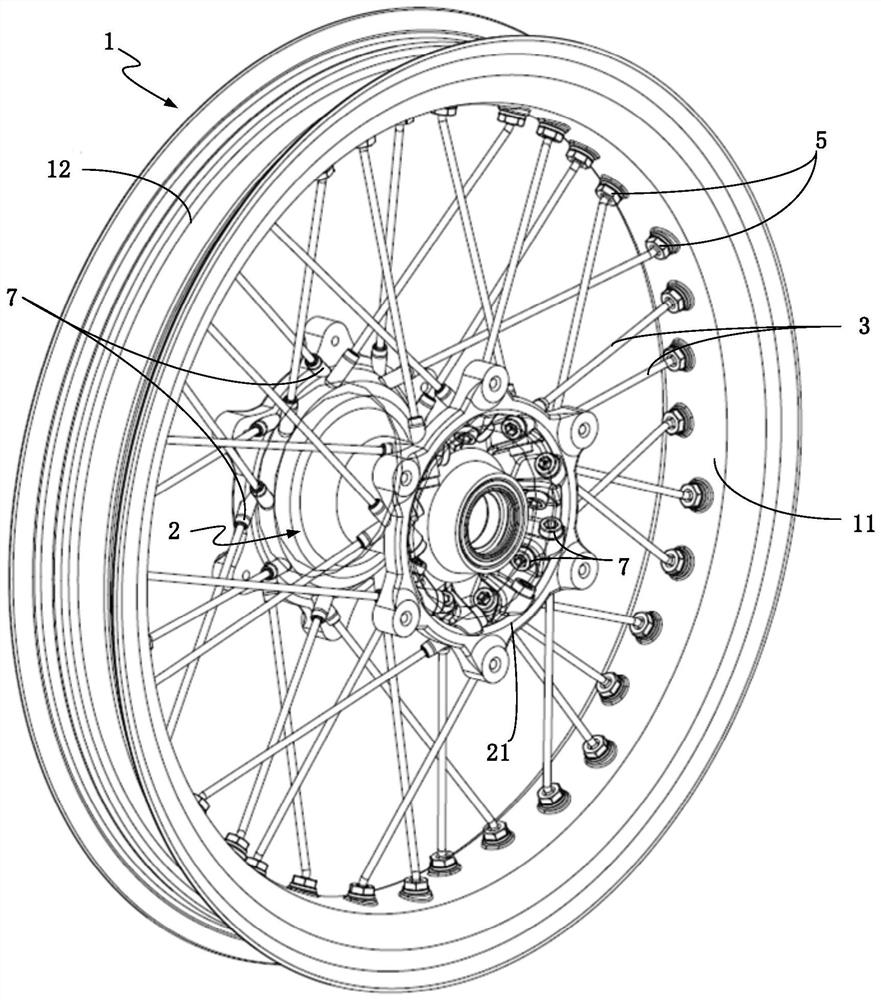

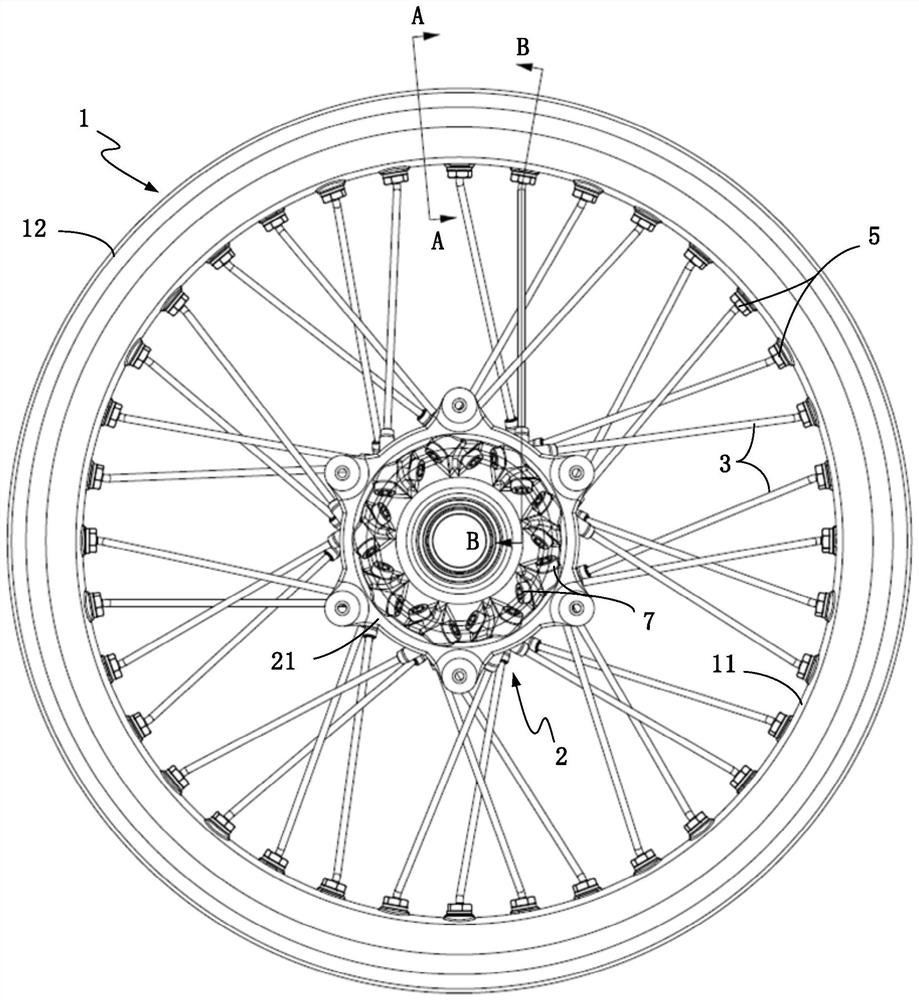

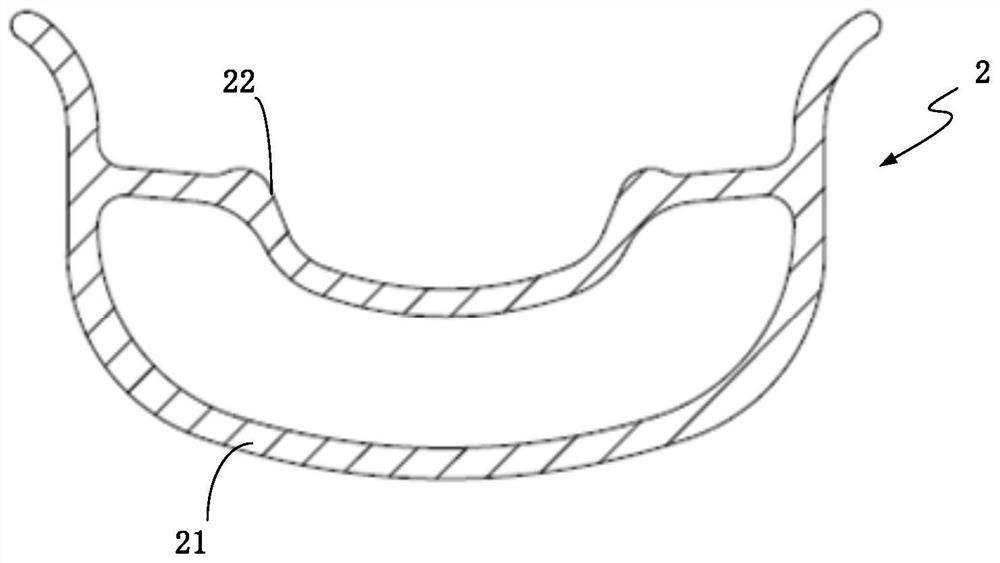

[0052] see Figure 1 to Figure 5 , the present embodiment provides a spoked motorcycle wheel, the spoked motorcycle wheel includes a rim 1 and a hub 2, the rim 1 is fastened to the hub 2 through a plurality of individual spokes 3. The rim 1 includes an inner rim 11 and an outer rim 12 that are integrally formed. In order to facilitate the rim 1 of the spoked motorcycle wheel to be extruded by a metal extrusion molding process, the inner rim 11 and the outer rim 12 are in any radial direction. A regular ring structure with consistent cross-sectional graphics.

[0053] Wherein, the inner rim 11 is disposed on the inner side of the outer rim 12 along the radial direction of the rim 1, and is configured to connect the spokes 3, which enables the outer rim 12 to obtain a non-porous radial outer end surface, which is configured to engage and hold Tire bead, so that when the spoked motorcycle wheel adopts a tubeless tire, there will be no air leakage between the tire bead of the tub...

Embodiment 2

[0065] see Figure 6 to Figure 9 , this embodiment shows another spoked motorcycle wheel, which adopts the same double-layer structure as the rim 1 of the spoked motorcycle wheel in Embodiment 1, which is composed of an inner rim 11 and an outer rim 12, the difference is that In this embodiment, the connection mode between the spoke 3 and the rim 1 and the hub 2 is different. The rim 1 is provided with a valve core hole 13 which is convenient for setting the valve core 8 to inflate the vacuum tire. The valve core 8 can pass through the sealing ring and the valve core hole. 13 joint airtight. Therefore, it should be noted that configuring the rim 1 to have a complete, non-porous radially outer end surface can be understood as that the radially outer end surface of the rim 1 is not provided with other components except the valve core hole 13 passing through the valve core 8 . through hole.

[0066] Specifically, in this embodiment, a plurality of spokes 3 are evenly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com