Preparation method of super-hydrophobic emulsion containing short fluorinated alkyl group

A technology of short fluorinated alkyl and fluorinated alkyl, which is applied in the field of superhydrophobic coating preparation, can solve the problems of threats to the environment of fluorine-containing reagents, and achieve excellent hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

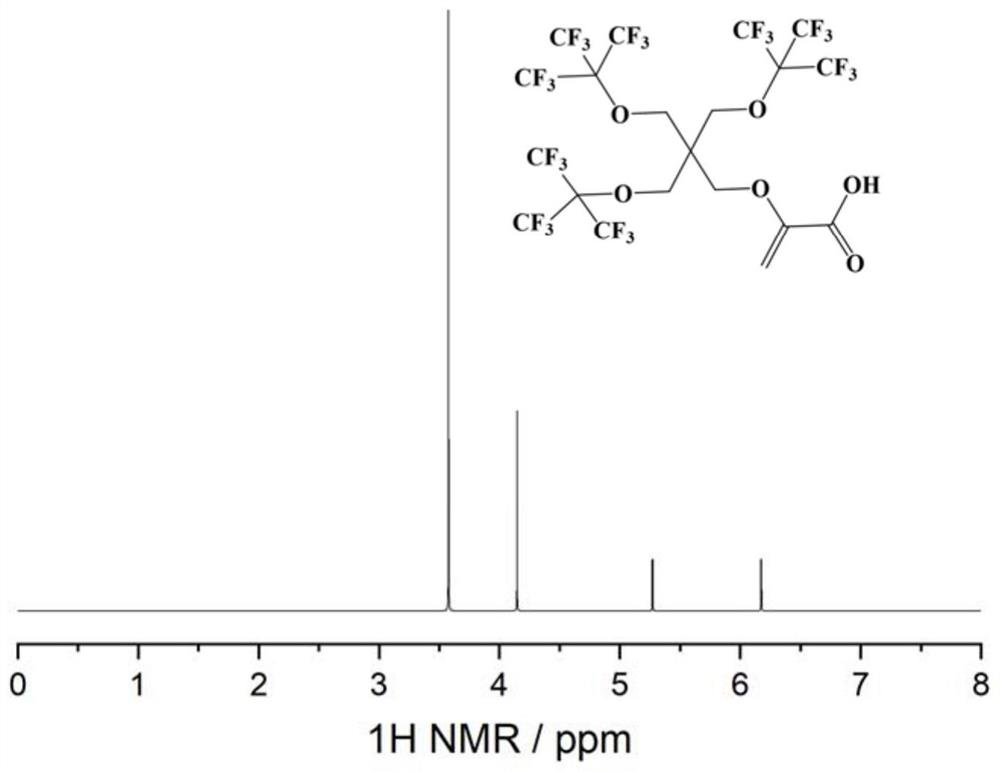

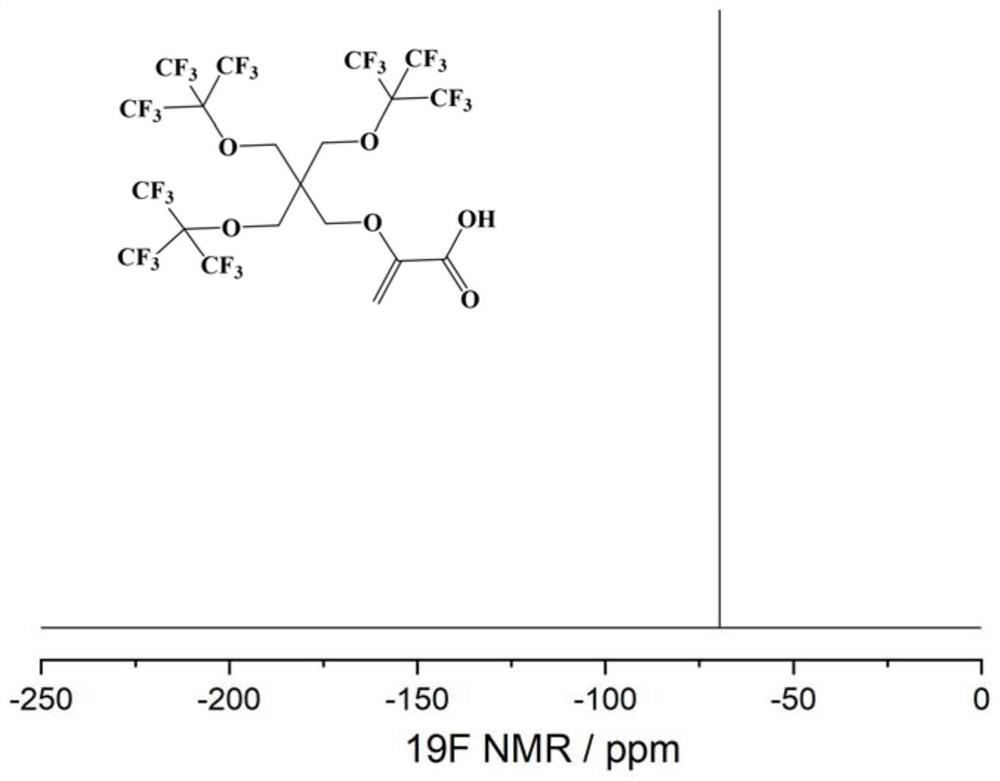

[0043] 1. Preparation of functional monomer BRFAE-1:

[0044] Dissolve 4.9 g of 3-perfluoro-tert-butanol-1-propanol, 4.4 g of triethylamine (TEA) in 144 mL of CH 2 Cl 2 4.4 g of acryloyl chloride was added to react under nitrogen gas, react at room temperature for 14 h, and remove the solvent to obtain the product BRFAE-1.

[0045] 2. Miniemulsion polymerization

[0046] Add 12.4g of butyl acrylate, 12.4g of methyl methacrylate, 2.4g of the product BRFAE-1 prepared above, 1.4g of co-stabilizer n-hexadecane, and crosslinking agent ethylene glycol methacrylate in a beaker (AAEM) 1.4g, reactive emulsifier sodium acrylamido isopropyl sulfonate (A-2444) 1.4g, initiator azobisisobutyronitrile (AIBN) 4.1g and 164g water, under ice bath conditions, in Ultrasound in the ultrasonic cell pulverizer for 3s, intermittent 4s, lasted 14min. The obtained pre-emulsion was put into a four-neck flask, purged with nitrogen for half an hour, and reacted at 74° C. for 12 hours to obtain a copol...

Embodiment 2

[0050] 1. Preparation of functional monomer BRFAE-2:

[0051] Dissolve 31.4 g of 2-amino-1-perfluoro-tert-butanol ethane hydrochloride, 3.1 g of triethylamine (TEA) in 144 mL of CH 2 Cl 2 In the middle, blow nitrogen, add 1.4g acryloyl chloride, react at room temperature for 24h, remove the solvent to obtain the product BRFAE-2

[0052] 2. Miniemulsion polymerization

[0053] In a beaker, add 12.4g butyl acrylate, 12.4g methyl methacrylate, 2.4g of the above-mentioned prepared product BRFAE-2, co-stabilizer octadecyl methacrylate 1.4g, crosslinking agent diacetone acrylamide ( DAAM) 1.4g, reactive emulsifier (UCAN-1) 1.4g, initiator potassium persulfate (KPS) 4.1g and 164g water, under the condition of ice bath, ultrasonic in the ultrasonic cell pulverizer for 3s, intermittent 4s, continuous 14min. The obtained pre-emulsion was put into a four-neck flask, purged with nitrogen for half an hour, and reacted at 74° C. for 12 hours to obtain a copolymer emulsion.

[0054] 3. ...

Embodiment 3

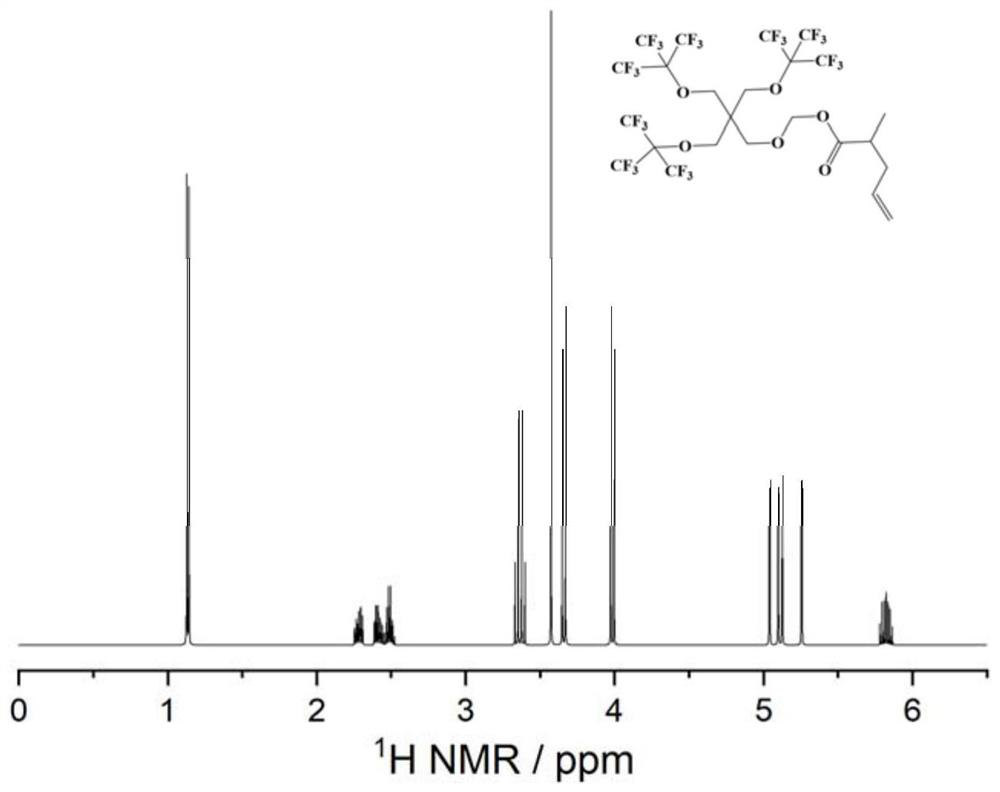

[0057] 1. Preparation of functional monomer BRFAE-4:

[0058] 4.4g 2-allyloxymethyl-2-ethyl-1,3-propanediol, 13.4g diethyl azodicarboxylate (DEAD), 19.7g triphenylphosphine (Ph3P), 17.7g perfluoro tertiary Butanol was dissolved in 144mL tetrahydrofuran (THF), nitrogen was blown, and the reaction was carried out at 44°C for 22h to obtain the product BRFAE-4.

[0059] 2. Miniemulsion polymerization

[0060] Add 12.4g of isooctyl acrylate, 12.4g of methyl methacrylate, 2.4g of the product BRFAE-4 prepared above, 1.4g of co-stabilizer cetyl alcohol polystyrene, crosslinking agent ethylene glycol diacrylate in the beaker 1.4g, reactive emulsifier containing allyl special alcohol ether sulfate (NRS-14) 1.4g, initiator ammonium persulfate (APS) 4.1g and 164g water, under ice bath conditions, in ultrasonic cell pulverizer Moderate ultrasound 3s, intermittent 4s, lasted 14min. The obtained pre-emulsion was put into a four-neck flask, purged with nitrogen for half an hour, and reacte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap