High-gloss varnish, preparation method and application thereof

A clear topcoat and high-gloss technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of affecting the sound of musical instruments, brittle adhesion of paint films, and easy pinholes, etc., to improve fullness and high adhesion , the effect of reducing the amount of paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

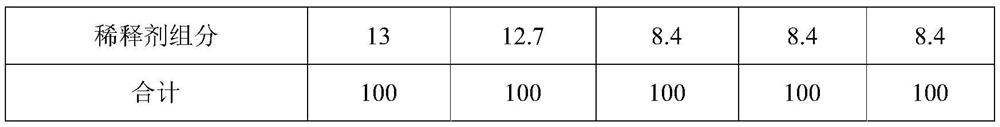

Embodiment 1

[0022] 1. Preparation of unsaturated resin

[0023] (1) Add 25g of dipentadiene petroleum resin (DCPD) and 95mL of n-heptane into a four-necked flask equipped with a stirrer, a thermometer, and a reflux condenser, start stirring, adjust the temperature, dissolve the petroleum resin, and heat up to 85 0.75 g of azobisisobutyronitrile (AIBN) was added, and 28 mL of glycidyl methacrylate was slowly added dropwise. After the reaction was completed, a crude product was obtained.

[0024] (2) Add a certain amount of absolute ethanol solution to the crude product, precipitate, filter with suction, and finally place the product in a drying oven at 60°C to dry to constant weight to obtain acrylated DCPD.

[0025] 2. Preparation of Fatty Acid Resin

[0026] Step 1: Add 21.11g of polyether diol and 19.03g of isophorone diisocyanate in a four-necked flask equipped with a mechanical stirrer, a thermometer and a reflux condenser, stir evenly, and then add 0.1 g of tributyl tin hydride;

...

Embodiment 2

[0054] 1. Preparation of Aliphatic Polyurethane

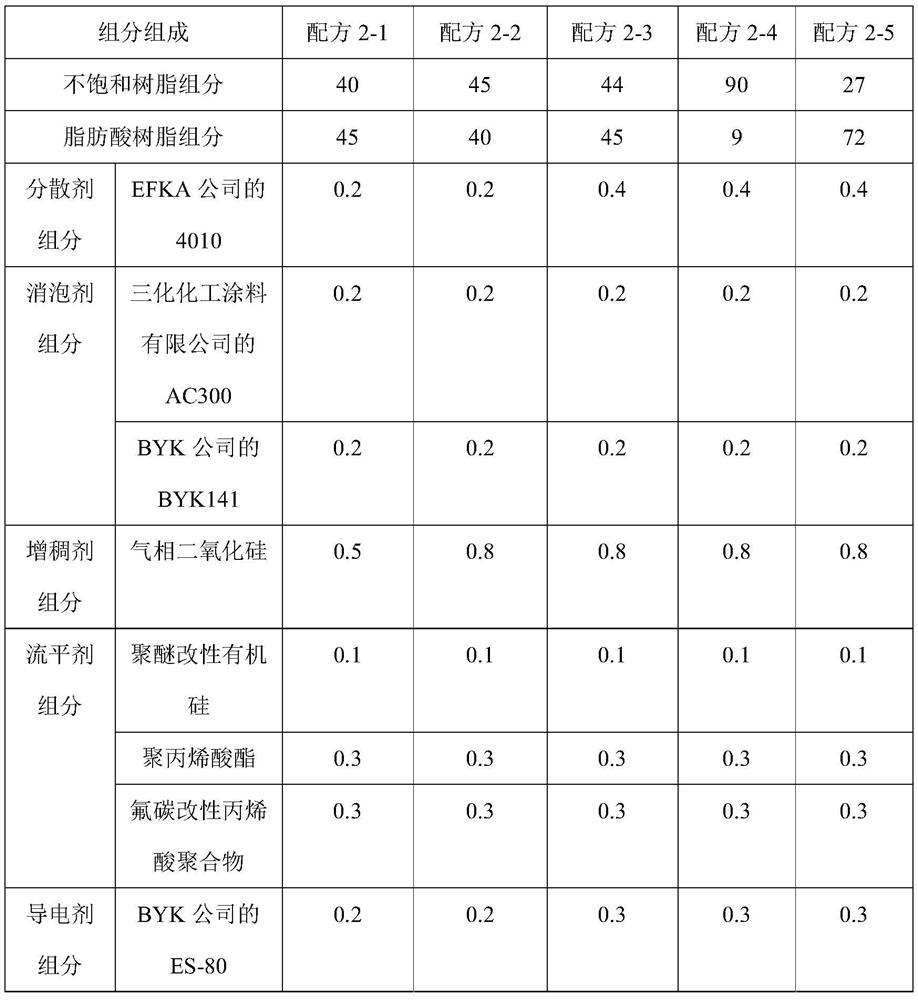

[0055] 1.1 How to set up treatment groups

[0056] Set up 5 groups of treatment groups, marked as treatment 1, treatment 2, treatment 3, treatment 4 and treatment 5 respectively, prepare the aliphatic polyurethane of mercapto-terminated modification, the operation method of each treatment group is as follows.

[0057] (1) Processing 1

[0058] Step 1: Add 21.11g of polyether glycol and 19.03g of isophorone diisocyanate in a four-necked flask equipped with a mechanical stirrer, a thermometer and a reflux condenser, stir evenly, then add 0.15 g of dilauric acid therein Dibutyltin;

[0059] Step 2: heating the mixed solution obtained in the step 1 to 70°C and keeping it warm for 5 hours;

[0060] Step 3: Add dimethylolpropionic acid (3.02g) / N-methylpyrrolidone (7g) solution to the mixed solution treated in step 2, so that the temperature of the resulting mixed solution is maintained at 70°C and kept for 5 hours ;

[0061] Ste...

Embodiment 3

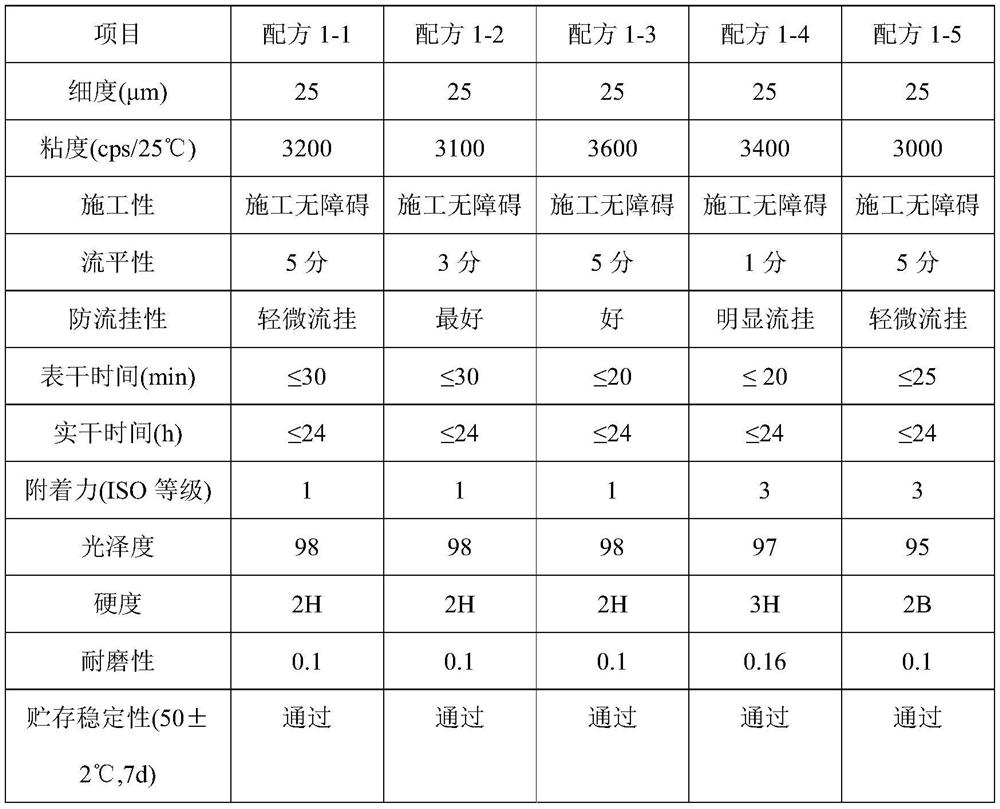

[0099] 1. Explore the experiment setting method

[0100] This example is based on the performance test results of Example 1, using the formula 1-3 in Example 1 as the basic formula, changing the composition of the leveling agent component in the formula, and exploring the physical and chemical effects of the leveling agent component on the high-gloss clear topcoat performance impact. Prepare the test leveling agent component of this embodiment according to the component composition shown in table 4, and use the leveling agent component adopted in formula 1-3 in embodiment 1 as the contrast leveling agent of this embodiment components.

[0101] Table 4 The test leveling agent component composition of this embodiment (mass parts)

[0102]

[0103] Adopt the leveling agent component A~F of this embodiment to replace the leveling agent component in the formula 1-3 of embodiment 1 respectively, prepare high-gloss clear topcoat. In addition to the leveling agent components, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com