Continuous heating furnace arrangement mode for thick plate production and steel pumping method through same

A heating furnace, continuous technology, applied in workpiece heating devices, heat treatment furnaces, furnaces, etc., to reduce costs, optimize production efficiency, and speed up logistics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 3

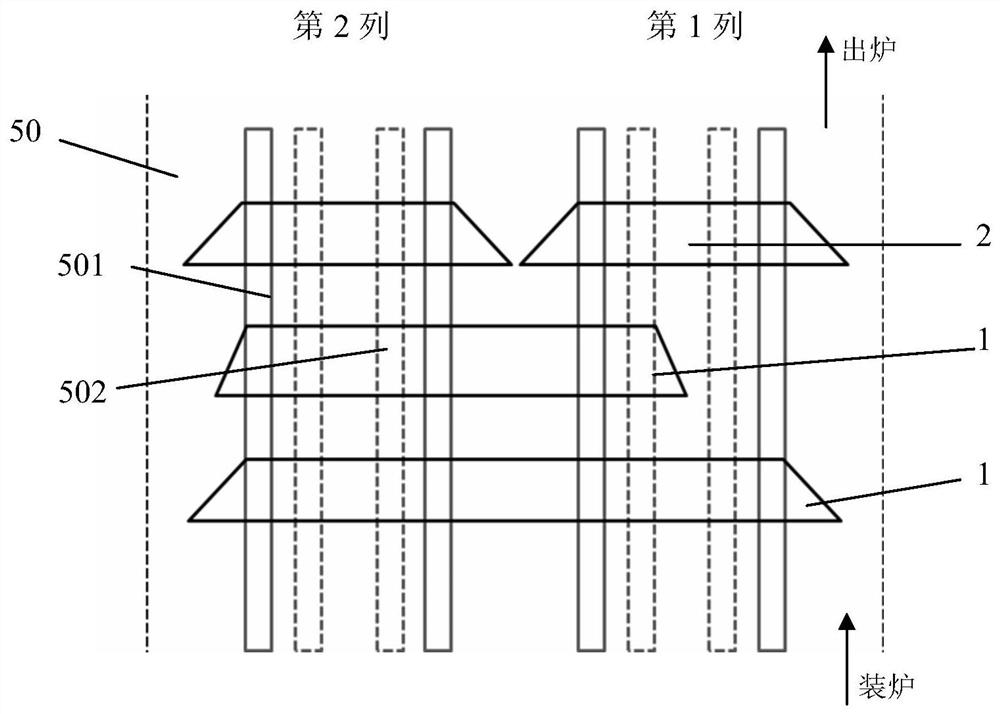

[0055] Example 1 Steel drawing mode combined with cut-to-length billet and long billet in three heating furnaces

[0056] In this embodiment, there are the following six typical combinations. The number of pieces loaded into continuous small batches of long blanks is 12, 15, and 18 pieces per furnace, and the number of pieces loaded into continuous small batches of long billets matched with them The number is 12 or 18 pieces per furnace.

[0057] see figure 2 , 12 long billets 1 and 12 cut-to-length billets 2 are arranged in succession.

[0058] It has 3 walking beam continuous heating furnaces that can meet the annual production capacity of 3 million tons of thick plate rolling. The rated hourly output of each heating furnace is 330t / h, and the maximum hourly output is 360t / h. In this rolling plan, the specification range of cut-to-length billet 2 is about 227mm×1900mm×3500mm, and the specification range of long billet 1 is about 227mm×1900mm×8000mm, and the number of slab...

Embodiment 2

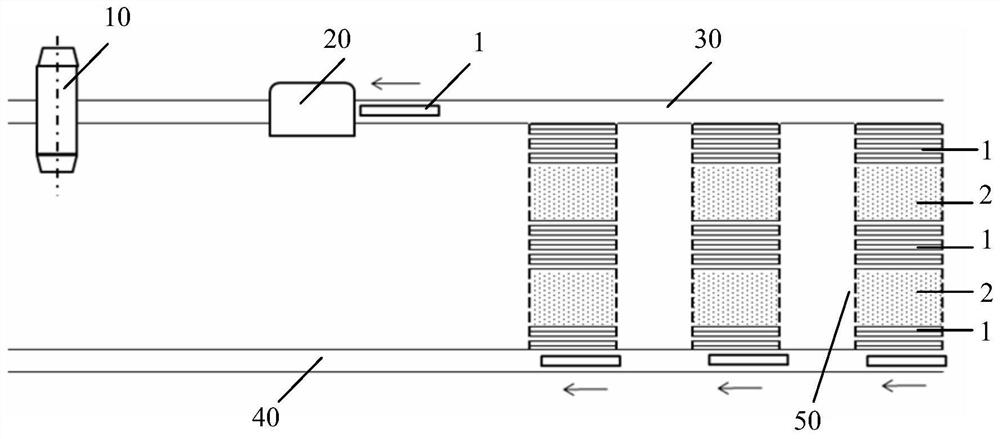

[0079] see Figure 8 , Two heating furnaces for fixed-length billets and one heating furnace for long billet drawing.

[0080] It has 3 walking beam continuous heating furnaces that can meet the annual production capacity of 3 million tons of thick plate rolling. The rated hourly output of each heating furnace is 330t / h, and the maximum hourly output is 360t / h. In this rolling plan, the specification range of the cut billet is about 227mm×1900mm×3500mm, the hot charging temperature is about 500°C and the target release temperature is 1080°C, the specification range of the long billet is about 227mm×1900mm×8000mm, the cold billet is loaded and the target release temperature is 1150°C. At this time, the number of fixed-length billets is far more than that of long billets. It is not suitable to arrange long billets and fixed-size billets into the furnace at intervals of small batches. One heating furnace is used as a buffer adjustment, and the other two heating furnaces are used...

Embodiment 3

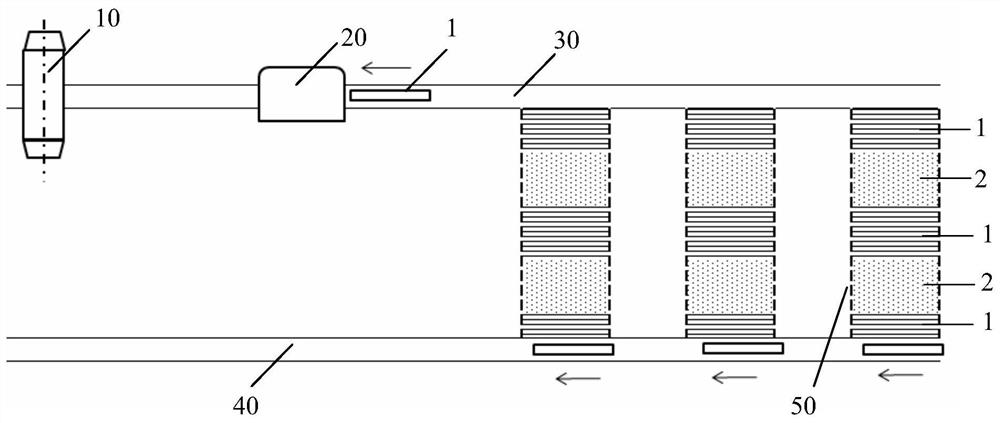

[0083] see Figure 9 , Two heating furnaces for fixed-length billets and one heating furnace for long billet drawing.

[0084] It has 3 walking beam continuous heating furnaces that can meet the annual production capacity of 3 million tons of thick plate rolling. The rated hourly output of each heating furnace is 330t / h, and the maximum hourly output is 360t / h. In this rolling plan, the specification range of cut-to-length billets is about 227mm×1900mm×3500mm, which is cold loaded into the furnace and the target furnace temperature is 1150°C, and the long billet specification range is about 227mm×1900mm×8000mm, and the hot charging temperature is about 500°C and the target furnace temperature is 1080°C, at this time, the number of long billets is far more than that of cut-to-length billets, and it is not suitable to arrange long billets and cut-to-size billets into the furnace at intervals of small batches, so the cut-to-length billets are arranged in a centralized manner near...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com