High-strength wheelchair front fork suspension structure and working method

A working method and high-strength technology, which can be used in patient chairs or special transportation tools, springs/shock absorbers, and vehicle rescue, which can solve the problem that the shock absorption capacity cannot be adjusted freely, cannot meet the needs of use, and shock absorption Ineffective and other problems, to achieve the effect of easy manufacture and use, protection and safety, and meet the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

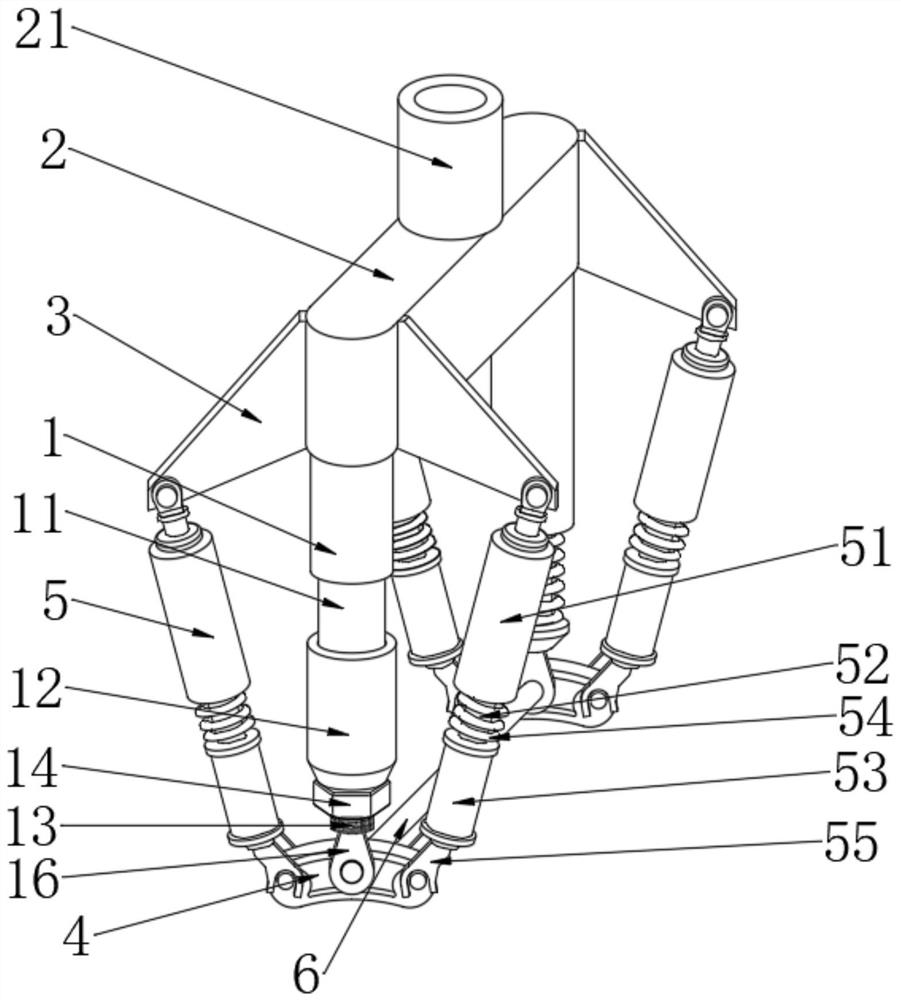

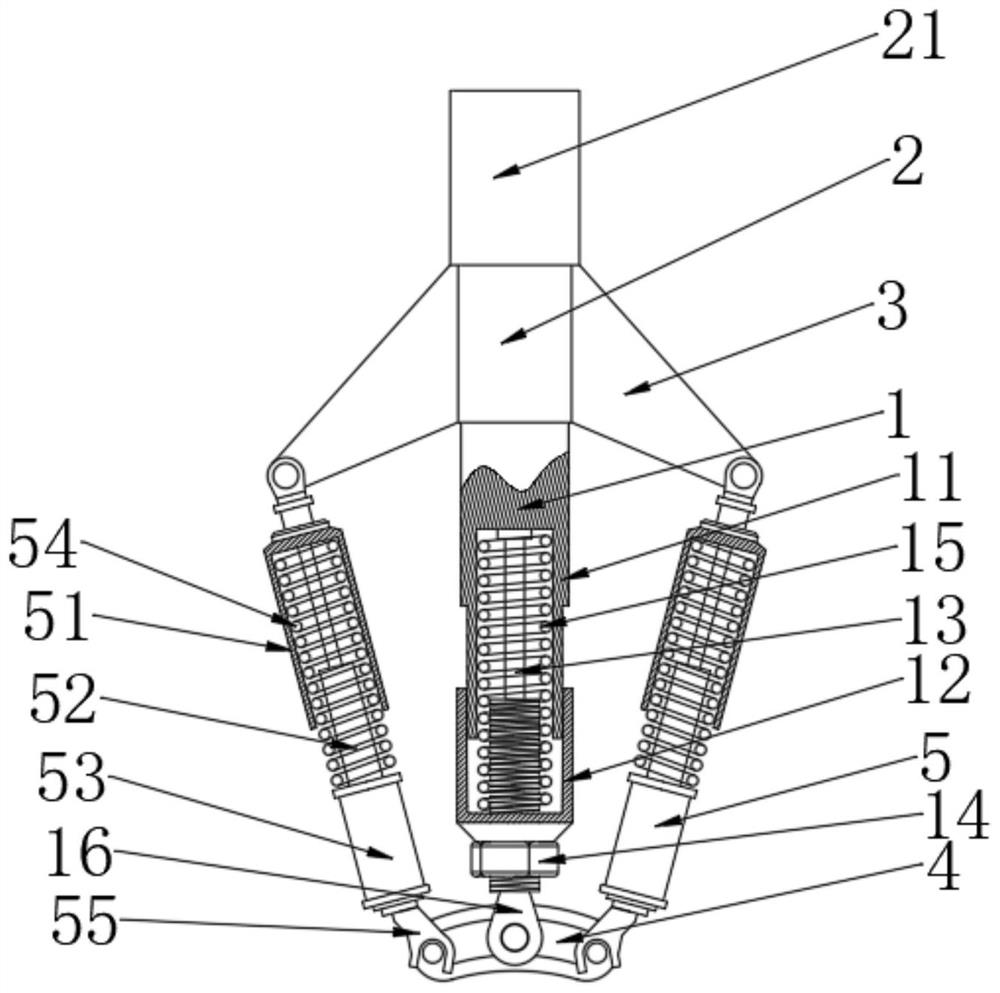

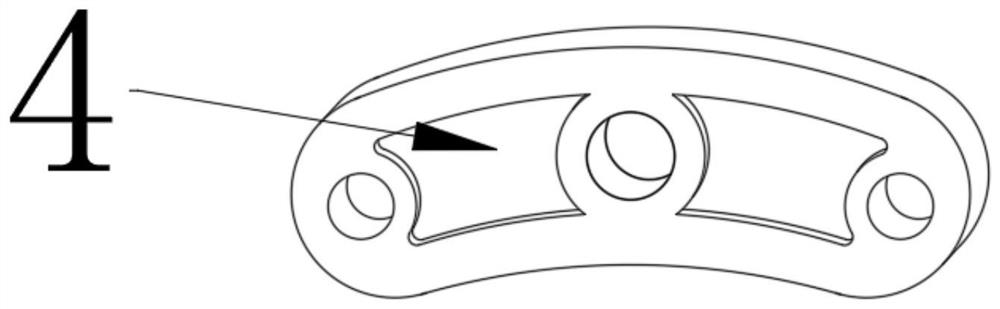

[0022] Such as Figure 1-3 A high-strength wheelchair front fork shock-absorbing structure and working method shown include two front fork frames 1 arranged symmetrically, and the two front fork frames 1 are connected by a connecting plate 2 at the upper end; Two groups of hinged ears 3 are arranged symmetrically on both sides, and the hinged ears 3 are arranged above the front fork frame 1; It is hinged with the center of the rocker arm 4, and a wheel shaft 6 is arranged between the center of each rocker arm 4 of the chain; the two sides of the front fork frame 1 are symmetrically provided with a shock absorber 5, and the upper end of the shock absorber 5 The part is hinged with the end of the hinge ear 3, and the lower end of the shock absorber 5 is hinged with the end of the rocker arm 4. An upper connecting block 21 is arranged at the middle of the upper end of the connecting plate 2, and the upper connecting block 21 is connected with the wheelchair frame.

[0023] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com