Fault positioning method and device for gas-insulated metal-enclosed power transmission line

A technology for gas-insulated metal and power transmission lines, which is applied to fault locations, fault detection by conductor type, measurement devices, etc., can solve problems such as low fault location sensitivity, and achieve the effect of avoiding further development, sensitive fault location, and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

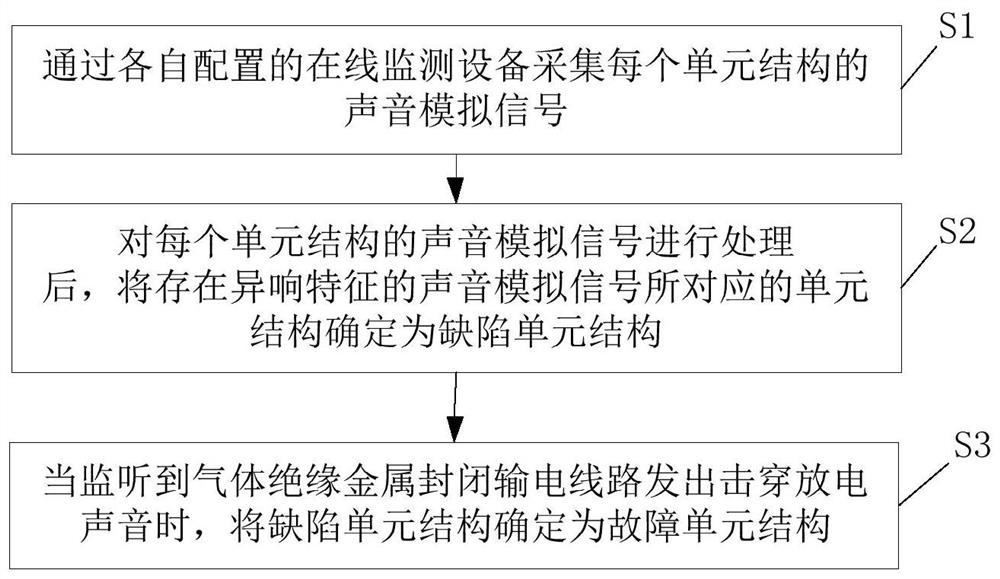

[0062] Such as figure 1 As shown, this embodiment provides a fault location method for gas-insulated metal-enclosed transmission lines, including the following steps:

[0063] S1: Acquire the sound analog signal of each unit structure through the online monitoring equipment configured separately.

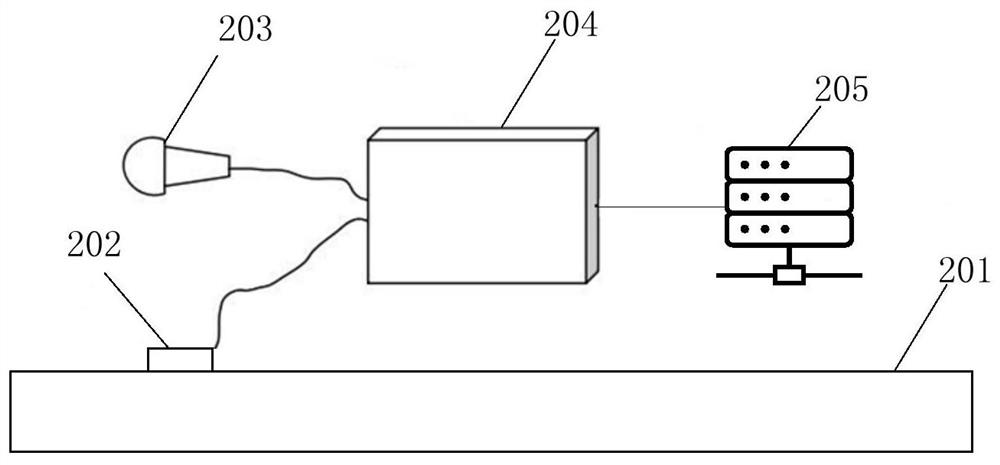

[0064] In the embodiment of the present invention, the gas-insulated metal-enclosed transmission line (that is, GIL equipment) includes a plurality of unit structures 201 connected in sequence, and each unit structure 201 is equipped with a set of online monitoring equipment. Taking a unit structure 201 as an example, as figure 2 As shown, the online monitoring equipment includes an acceleration vibration sensor 202 and an environmental noise sensor 203, wherein the acceleration vibration sensor 202 is arranged on the upper surface of the unit structure 201, and the environmental noise sensor 203 is arranged near the unit structure 201, and the acceleration vibration sensor 202 and...

Embodiment 2

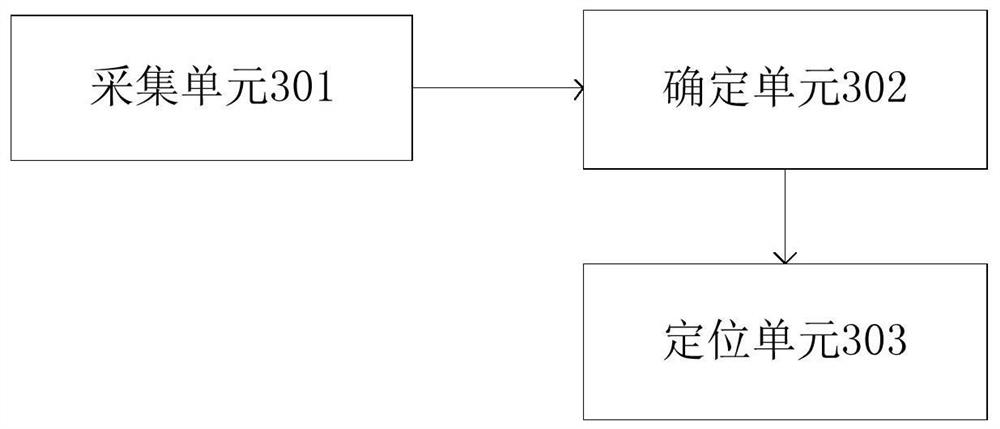

[0110] Such as image 3 As shown, this embodiment provides a fault location device for a gas-insulated metal-enclosed transmission line, wherein the gas-insulated metal-enclosed transmission line includes a plurality of unit structures connected in sequence, and each unit structure is equipped with a set of on-line monitoring equipment; The positioning device includes a collection unit 301, a determination unit 302 and a positioning unit 303, wherein:

[0111] The collection unit 301 is used to collect the sound analog signal of each unit structure through the online monitoring equipment configured respectively.

[0112] The determining unit 302 is configured to, after processing the sound analog signal of each unit structure, determine the unit structure corresponding to the sound analog signal with abnormal sound characteristics as a defective unit structure.

[0113] The locating unit 303 is configured to determine the defective unit structure as a faulty unit structure wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com