Numerically-controlled lathe remote data acquisition and analysis system

A technology of remote data collection and analysis, applied in transmission systems, signal transmission systems, instruments, etc., can solve problems such as time-consuming, CNC lathes cannot remotely monitor the running status, poor communication, etc., to save time and financial resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

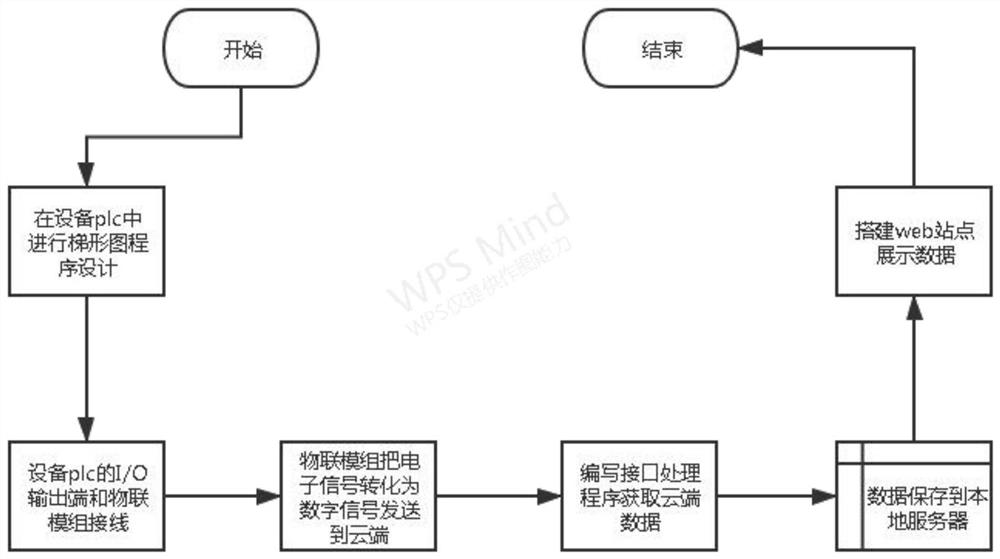

[0021] Attached below figure 1 Further explain the technical scheme of the present invention

[0022] As shown in the figure, a remote data acquisition and analysis system for a CNC lathe includes a CNC machine tool, a data platform for receiving and storing data, and the data acquisition and analysis system also includes red, yellow, and green alarm lights and a wireless module for transmitting signals. group; there are 7 connecting lines for the three-color alarm light, which are red, yellow, green, black and three gray lines, which are divided into three types: light signal line, sound line and public line, among which red, yellow and green are light signals line, three gray lines are sound lines, and one black line is public line;

[0023] An installation and operation method of a remote data acquisition and analysis system for a numerically controlled lathe comprises the following steps:

[0024] Step 1: When writing the ladder diagram control program for the PLC and ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com