Phase changing unit and valve timing changing device

A phase change and rotation phase technology, applied in valve devices, engine components, valve details, etc., can solve the problems of complex structure, large inertia moment, high cost, etc., and achieve the effect of simplifying structure, preventing damage, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

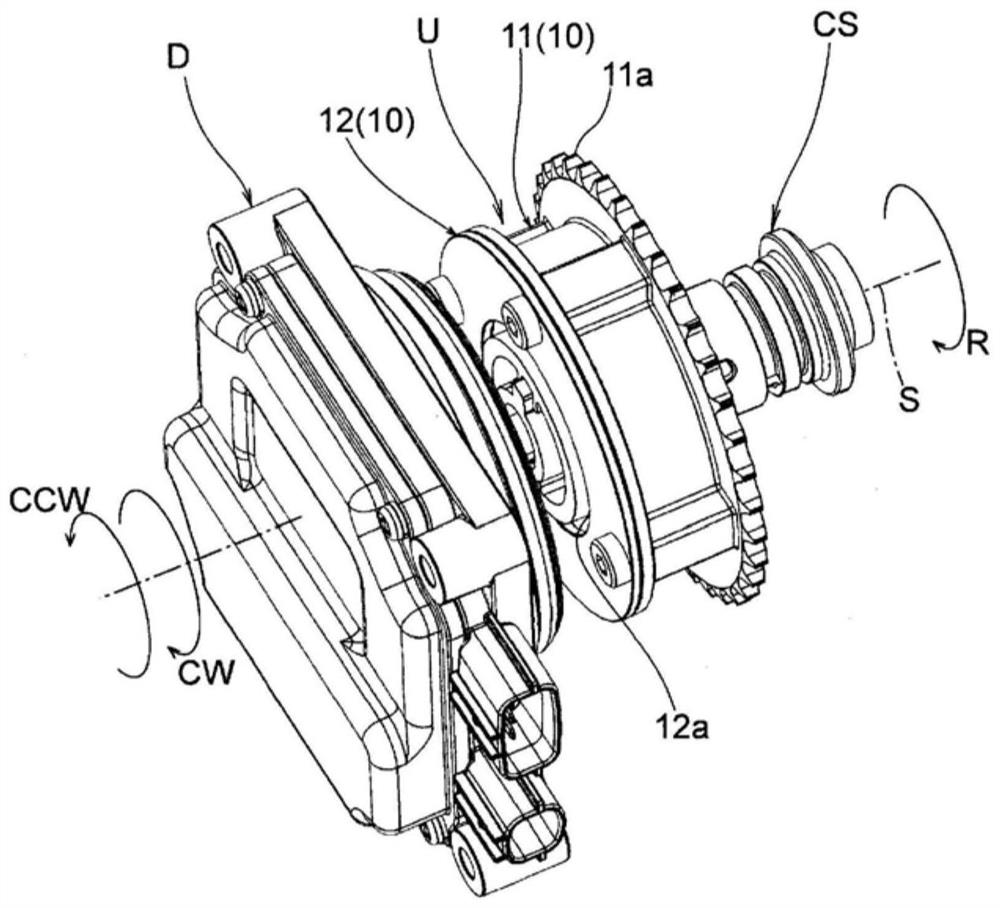

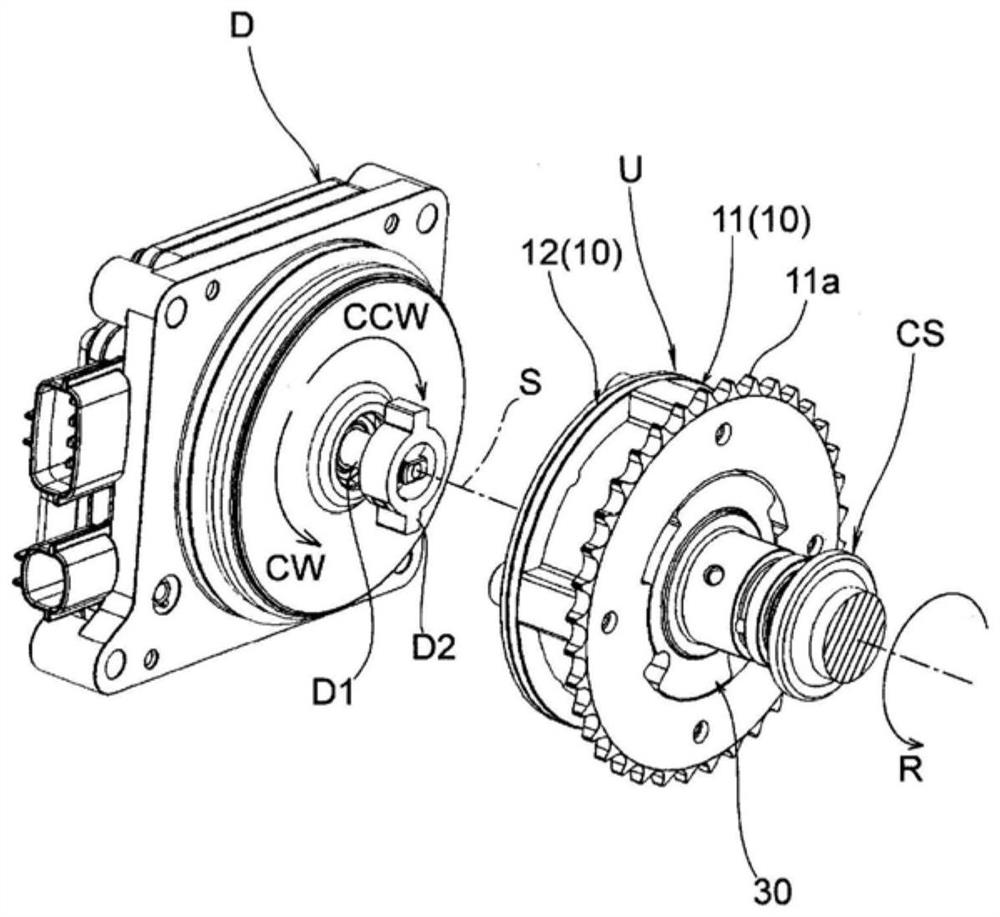

[0077] The valve timing changing device according to one embodiment is as follows: figure 1 As shown, a phase changing unit U is included to change the relative rotational phase of the camshaft CS and the sprocket 11a.

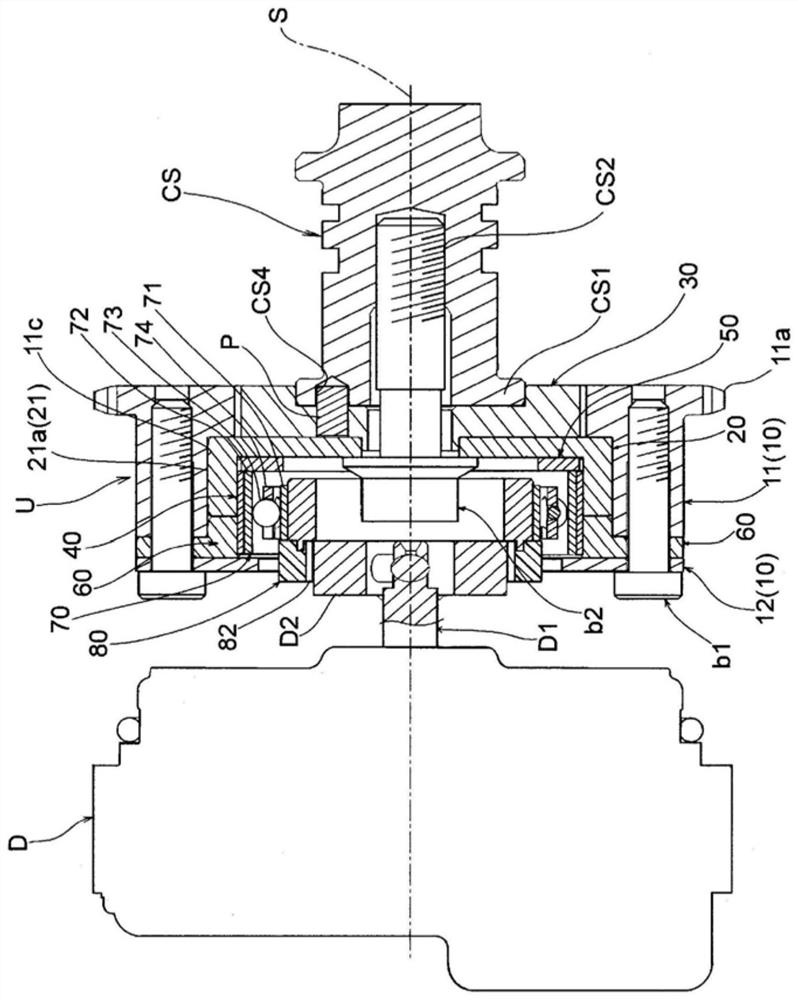

[0078] Here, the camshaft CS is taken as a direction around the axis S ( figure 1 in the R direction) to function as the first rotating body that rotates, such as Figure 5 As shown, it includes a brim-shaped fitting portion CS1, a screw hole CS2, an oil passage CS3, and a fitting hole CS4 of the positioning pin P.

[0079] The sprocket 11a forms a part of a second rotating body that rotates in one direction (R direction) around the axis S, and is interlocked with the rotation of the crankshaft via a chain.

[0080] Then, the phase changing unit U is appropriately driven and controlled by the electric motor D to change the opening / closin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com