Surface pretreatment method of railway wagon door in rail transit

A technology for surface pretreatment and railway freight cars, which is applied to the surface pretreatment, the device for coating the surface with liquid, the treatment device for used abrasives, etc. Use effect, affect the appearance of rail transit railway freight car doors, etc., to ensure safety, ensure rust removal and strengthening effect, and achieve the effect of continuous and stable shot blasting and rust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

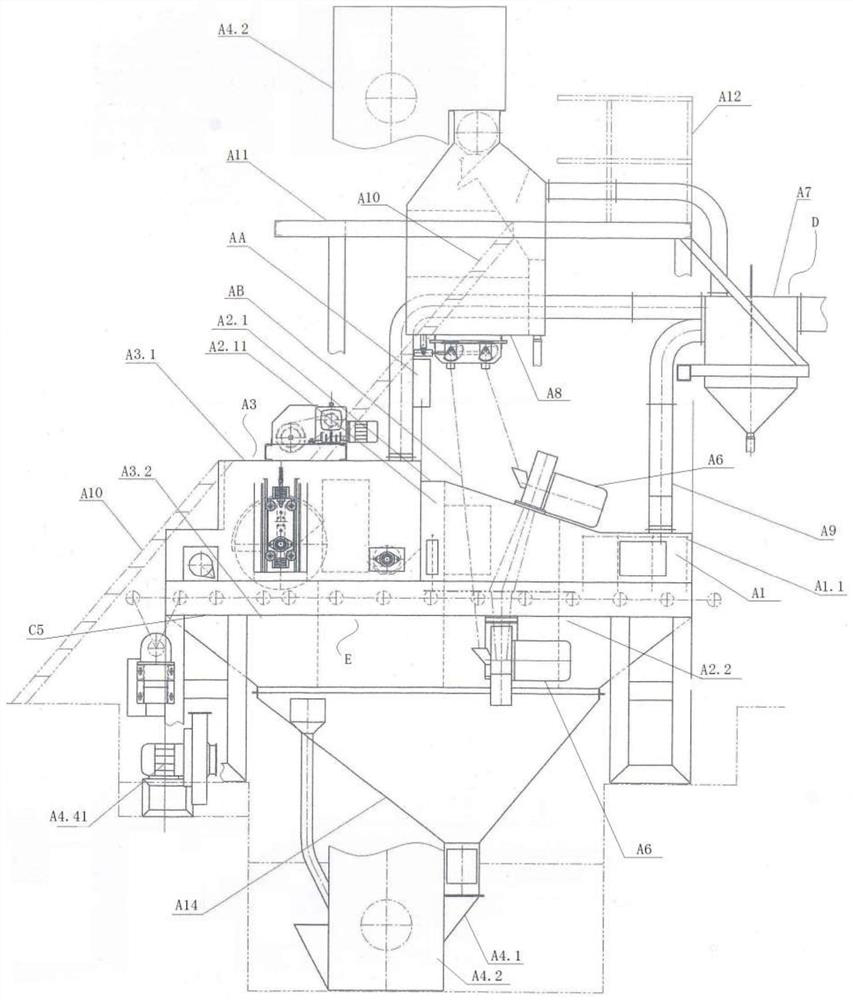

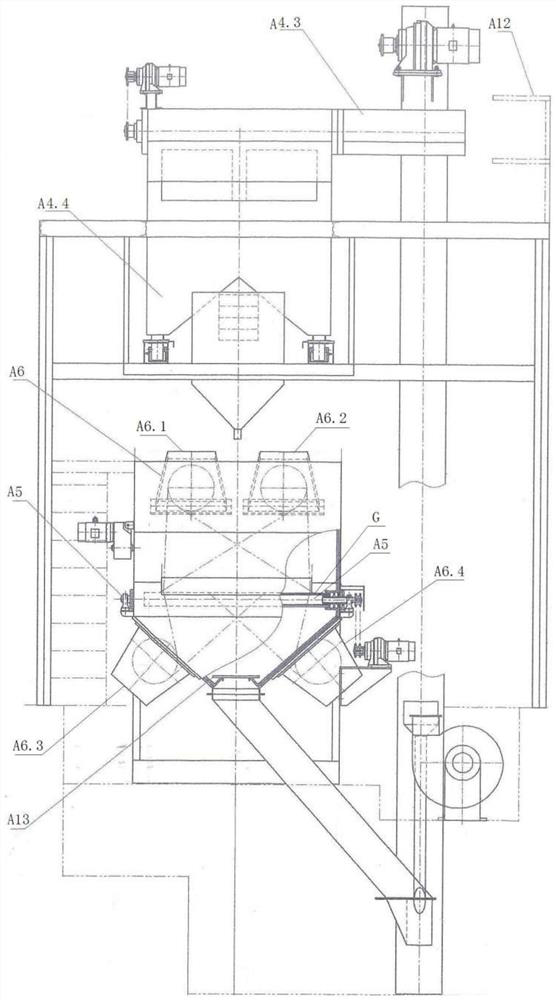

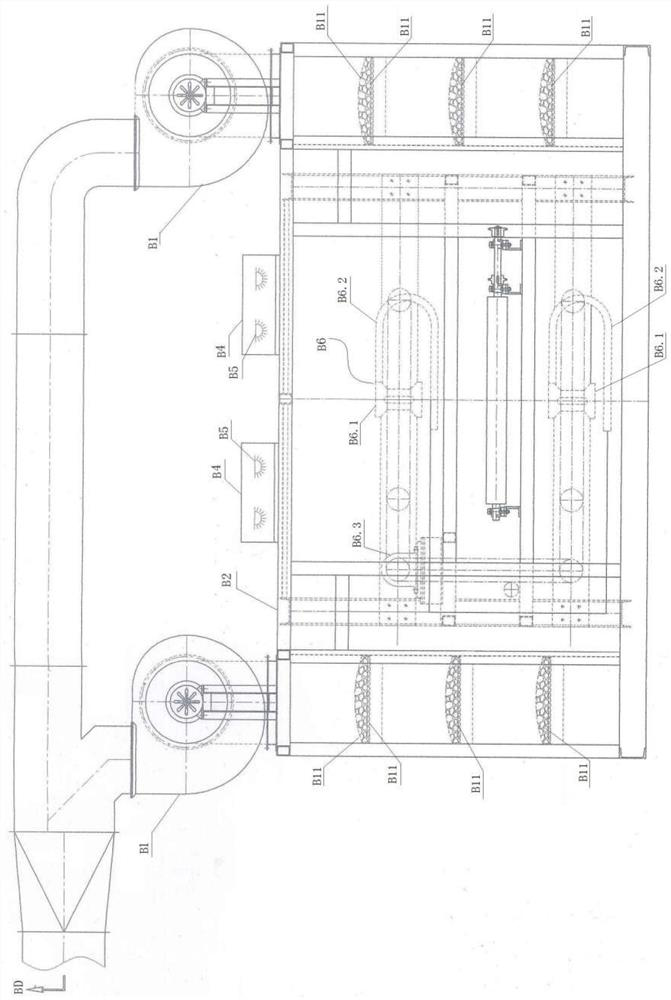

[0054] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

[0055] Referring to the accompanying drawings, it can be seen that the surface pretreatment method for rail freight car doors comprises the following steps,

[0056] Step 1: workpiece conveying;

[0057] The workpiece conveying system sends the workpieces to be processed into shot blasting room A, painting room B, drying room C and dust removal system D in sequence; among them, shot blasting room A includes shot blasting room A2 and cleaning room A3;

[0058] Step 2: Shot blasting;

[0059] Before and after the opening of the shot blasting room and cleaning room A, the dust removal system D is started; the dust removal system D sucks the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com