Wearing strip device

A wear and installation hole technology, which is applied in transportation and packaging, railway car body parts, railway car bodies, etc., can solve the problems of large loss of parts, short service life, high friction coefficient, etc., so as to prolong the service life, improve the use environment, The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

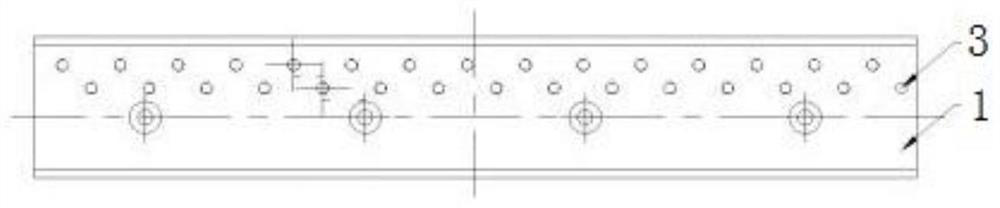

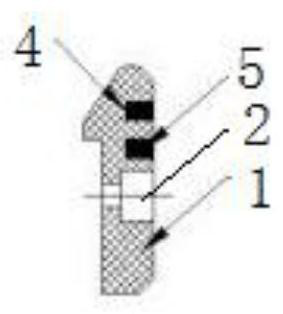

[0013] The main structure of the wear strip device involved in this embodiment includes a wear strip body 1, an installation hole 2, a blind hole 3, a glue layer 4 and a graphite column 5; the wear strip body 1 is provided with four through installation holes 2, and the installation holes 2. It is composed of upper and lower through-holes with circular frustum-shaped structures. The diameter of the upper circular platform is not equal to the diameter of the lower circular platform. The wear strip body 1 is also provided with 30 blind holes 3 with circular structures. The blind holes 3 Divided into upper and lower rows, arranged in parallel with each other, the blind hole 3 is provided with a glue layer 4 and a graphite column 5, and the glue layer 4 and the graphite column 5 are adhesively connected.

[0014] The mounting holes 2 involved in this embodiment are used for connecting with blocked components.

[0015] The shape and size of the wear strip device involved in this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com