Through passage floor system

A through-channel and floor technology, applied in the field of rail transit equipment, can solve the problems of noise pollution, short service life, large bearing load, etc., and achieve the effect of prolonging the service life, reducing the degree of wear, and reducing the number of replacements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

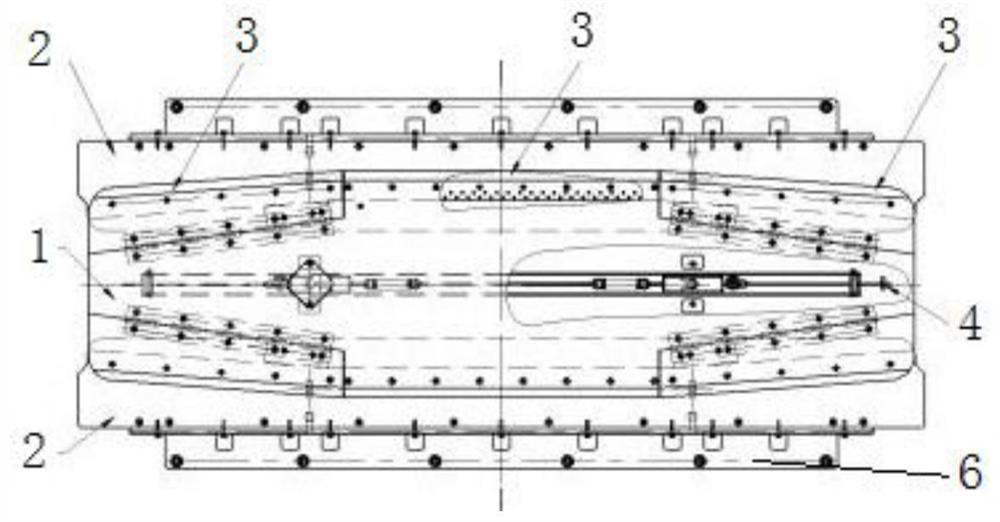

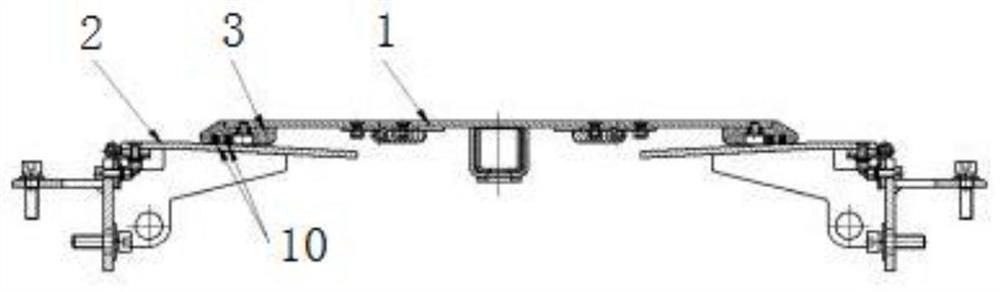

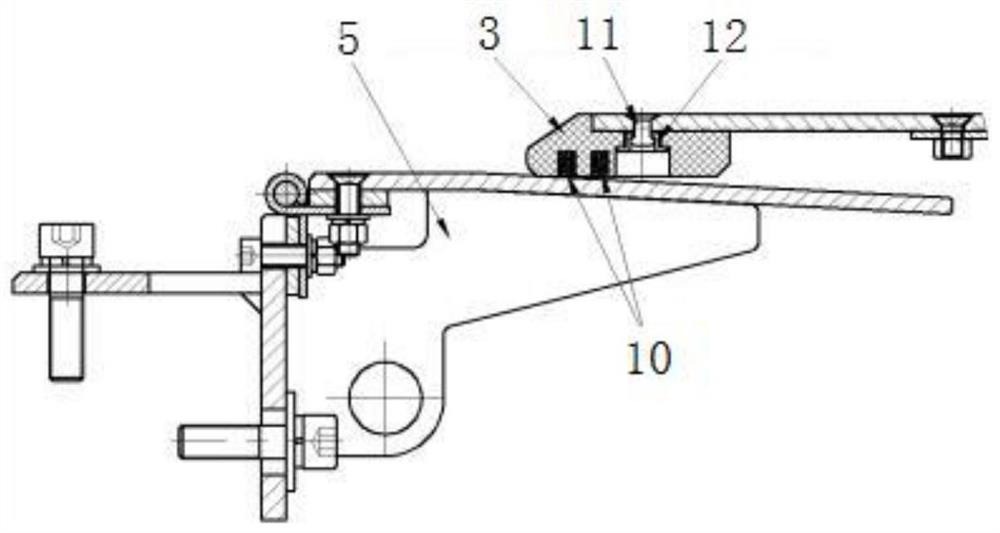

[0017] The main structure of the through-passage floor system involved in this embodiment includes a cross plate 1, a pedal 2, a wear strip 3, a connecting rod 4, a pedal support 5, a mounting hole 7, a blind hole 8, a glue layer 9, a graphite column 10, and a rivet 11 and the fixed sleeve 12; the long sides of the crossing plate 1 are respectively overlapped on the pedal 2, and the end of the overlapping plate 1 and the pedal 2 is intermittently provided with a wear strip 3, and the bottom of the crossing plate 1 passes through 2- The three connecting rods 4 are connected to the bottom of the pedal 2, and the pedal 2 is connected to the body frame 6 through the pedal support 5; the wear strip 3 is provided with four through mounting holes 7, and 30 different circular structures are also provided. The through blind holes 8 are divided into two rows and arranged in parallel with each other. The blind holes 8 are provided with a glue layer 9 and a graphite column 10, and the glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com