Coal gangue brick stacking, drying and transferring device

A technology of transfer device and drying device, which is applied in transportation and packaging, multi-axis trolleys, trolley accessories, etc., can solve the problems of long time, reduce the drying efficiency of coal gangue bricks, and inconvenient drying of coal gangue bricks, and achieve high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

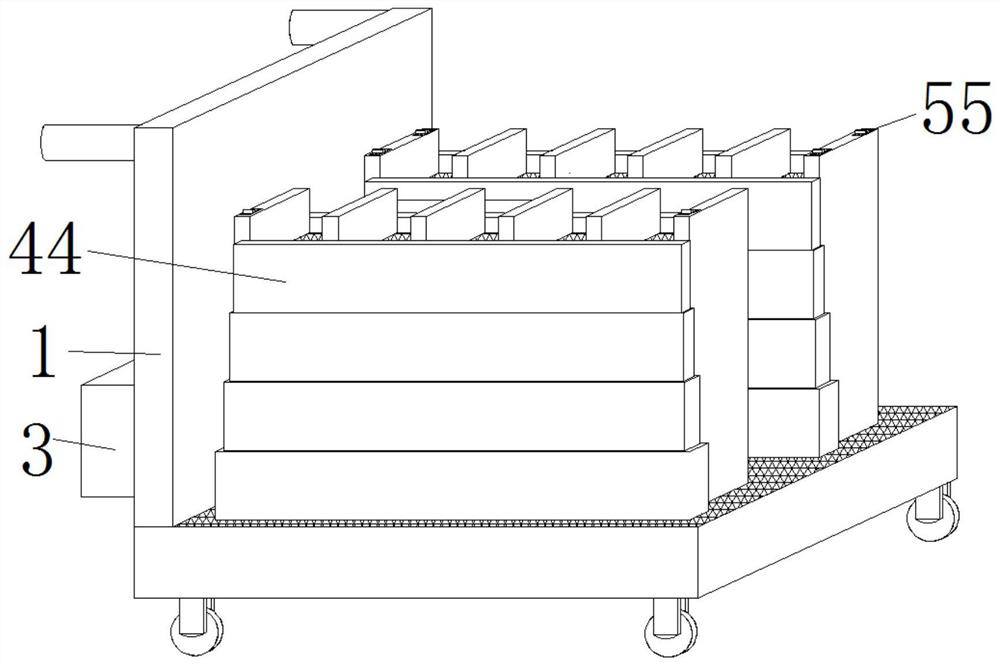

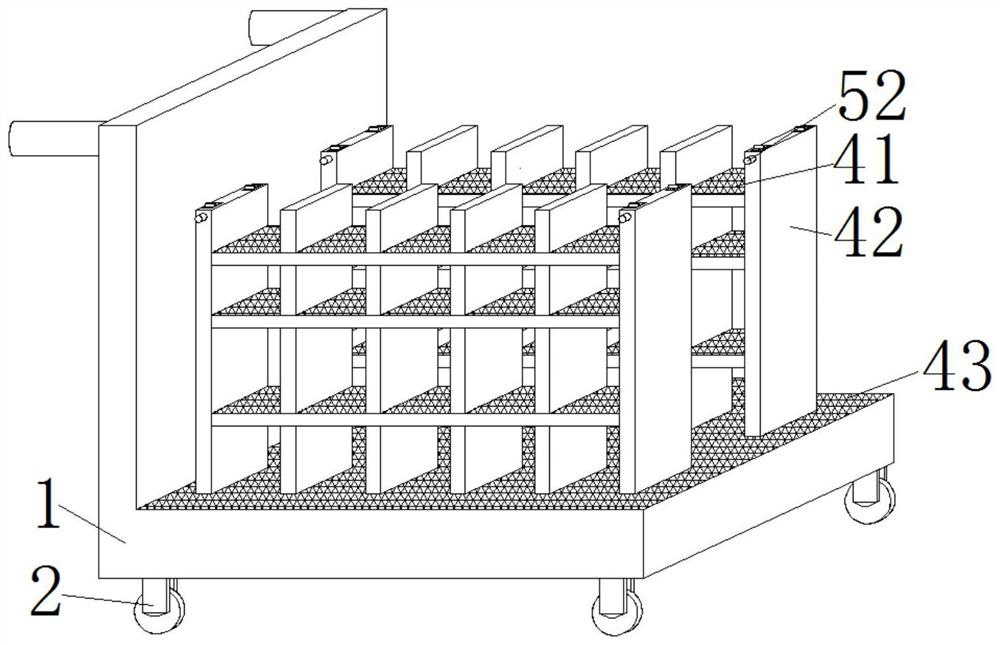

[0020] see Figure 1-4 , the present embodiment provides a dry transfer device for gangue bricks and bricks, including a trolley 1 and a universal wheel 2, the upper end of the universal wheel 2 is rotatably mounted on the lower end of the trolley 1, and the trolley 1 An installation box 3 is fixedly installed on one side, and a power supply is fixedly installed in the inner cavity of the installation box 3, wherein the power supply can provide power to the drying device 4, and the drying device 4 is arranged in the bottom inner cavity of the trolley 1 , wherein, the drying device 4 can dry the gangue bricks placed on the upper end of the drying device 4, and the upper end of the drying device 4 is provided with a connecting device 5, wherein the connecting device 5 can connect the drying device 4.

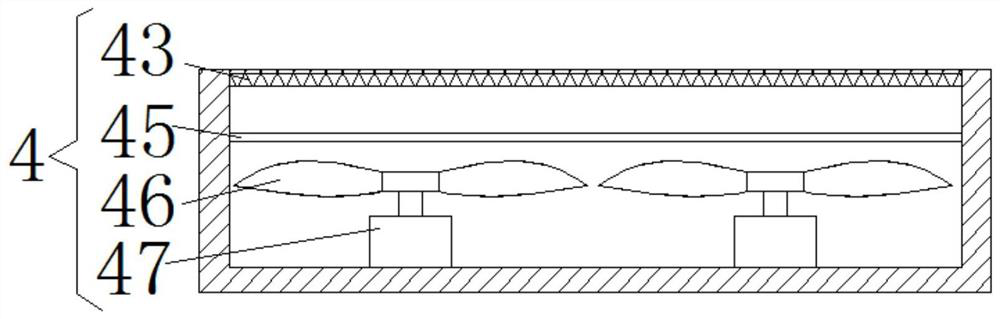

[0021] In order to solve the problem of how to place coal gangue bricks on the upper end of the cart 1, the drying device 4 includes a first support plate 42, a second support pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com