Filling production line

A production line, loading and unloading technology, applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of increasing production costs, stringing cups, and long conveying distance, and achieve the effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

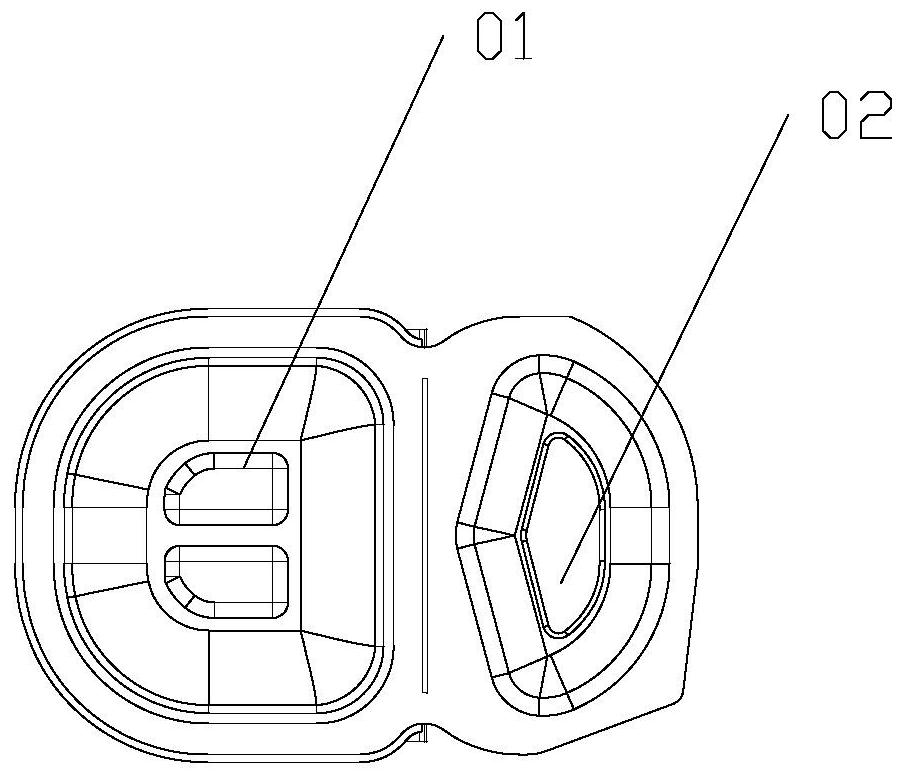

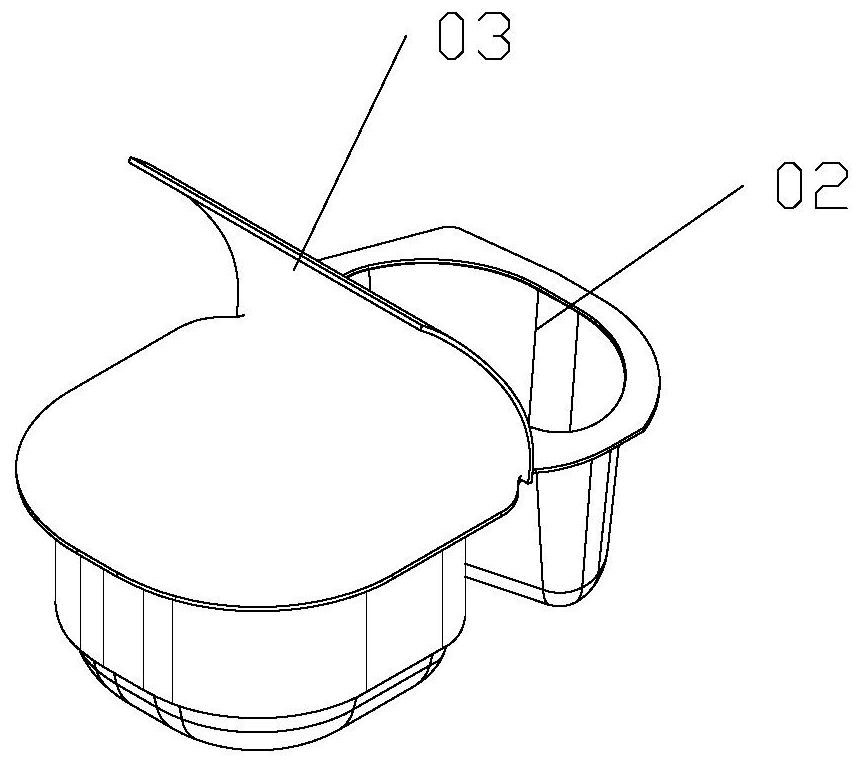

[0084] refer to Figure 1 to Figure 2 As shown, the yogurt cup in this embodiment has a first cavity 01 and a second cavity 02, the first cavity 01 and the second cavity 02 are respectively filled with different materials, the first cavity 01 and the second cavity After the body 02 is filled, the lid film is heat-sealed.

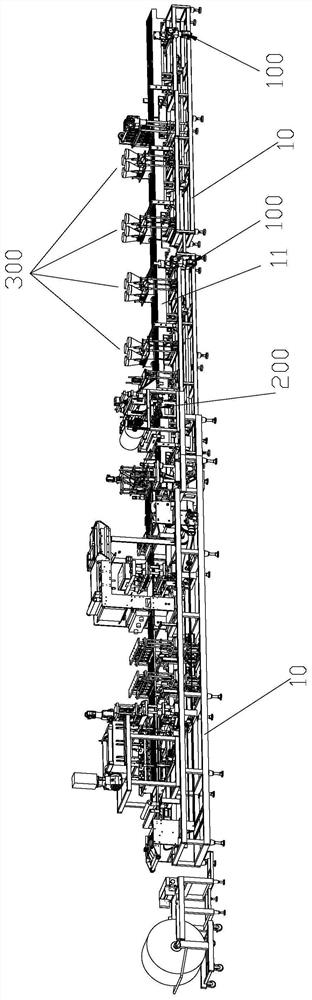

[0085] Such as Figure 3 to Figure 10 As shown, the filling production line for filling the above-mentioned yogurt cups in this embodiment includes a frame 10 and a material support assembly arranged on the frame 10. The material support assembly includes a plurality of horizontally equidistant and parallel to each other. Arranged supporting boards 11, the supporting boards 11 extend straight along the conveying direction of the yogurt cups, the two ends of a plurality of supporting boards 11 are fixed in series by rods 12, and the outermost supporting board 11 is fixed on the machine by a vertical board 13 On the frame 10, a straight delivery channel is f...

Embodiment 2

[0119]Compared with Embodiment 1, the difference of this embodiment is that the guide part is a guide sleeve, and the bottom end of the guide sleeve is connected with the top end of the rocker arm through pin rotation, and the connection part is a guide set at the bottom of the conveying plate and extends downward. column, and the guide sleeve is slidably fitted on the guide column.

Embodiment 3

[0121] Compared with Embodiment 1, the difference of this embodiment is that the two ends of the support rods are respectively fixedly connected with the support plate 211, and one of the support rods 212 is connected with the top end of the first rocker arm 243 and the bottom of the first rocker arm 243. The position between the two ends is rotatably connected, the other support bar 212 is rotatably connected with the top of the second rocker arm 246 , and the top of the connecting block 245 is rotatably connected with the support bar 212 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com