Automatic wastewater treatment equipment and using method thereof

A technology for treating equipment and waste water, which is applied in water/sewage treatment equipment, water/sewage treatment, chemical instruments and methods, etc. It can solve problems such as inability to screen and crush large particles of impurities, poor drainage, and blockage of screens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

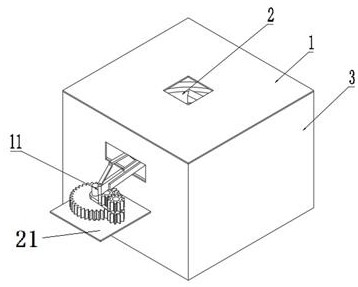

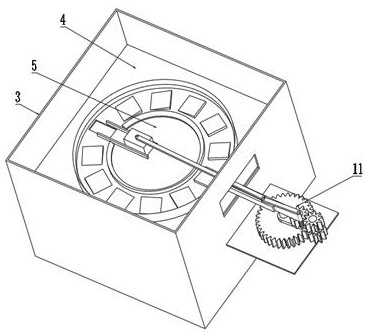

[0030] see Figure 1 to Figure 10 , The present invention provides a technical solution: an automatic treatment equipment for wastewater, which includes: a housing, a screen member 5, and a swing mechanism 11.

[0031] The housing includes an outer shell 3, the upper end of the outer shell 3 is fixed with a cover plate 1, the surface of the cover plate 1 is provided with a feed port 2, and a fixed plate 4 is fixedly connected with the cover plate 1 on the inner wall of the shell.

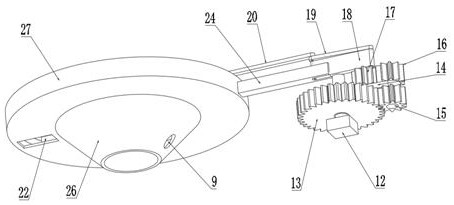

[0032] The screen member 5 includes a circular screening plate 29, the outer ring of the screening plate 29 is fixedly connected with a liquid blocking plate 28, and the outer coaxial line of the liquid blocking plate 28 is fixedly connected with a large particle impurity moving groove 30. The outer ring of the moving tank 30 is fixedly connected with the outer retaining ring 27, and the upper surface of the moving tank 30 for large particles of impurities is fixedly installed with guide blocks 6 ev...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 lies in that the use method of an automatic treatment equipment for waste water is different.

[0050] When the trajectory of the pin shaft 25 is as Figure 6 When shown, the movement process of the device is as follows:

[0051] said Figure 6 , the arc in the circle is the motion track of pin shaft 25.

[0052] The initial state of the device is that when the pin shaft 25 is at point B2, the screen member 5 rotates to the limit position on one side of the reference line G2 direction, which is called the highest point. by Figure 4 Elaborate for the base view. Figure 6 The middle reference line G2 is an extension line of the motion track of the slide plate 8 .

[0053] The initial state of the device is that the pin shaft 25 is at point B2, and the screen member 5 rotates to the highest point.

[0054] During the movement of the pin shaft 25 from A2 to B2, the swing mechanism 11 drives the screen member 5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com