Hoisting method for three-layer combined steel column sandwich heat preservation external wall panel of fabricated steel structure house

A technology of thermal insulation exterior wall and hoisting method, which is applied in building construction, construction, and building material processing, etc., to achieve the effect of good effect, stable installation, and reduction of potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

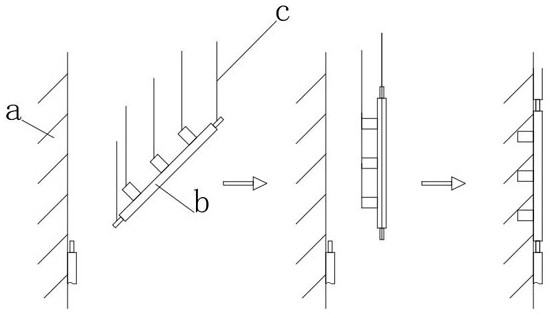

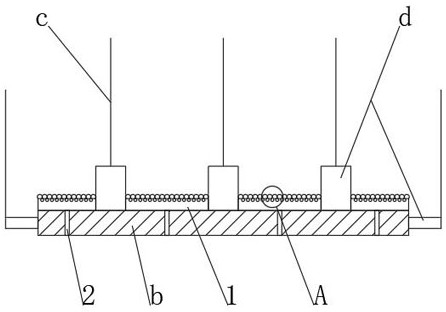

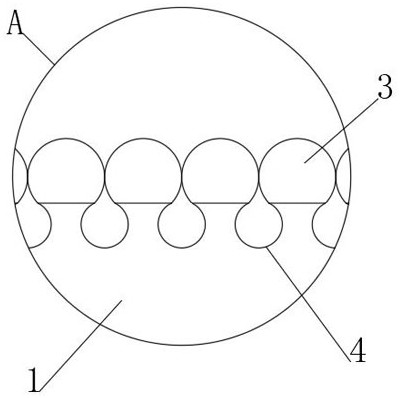

[0048] see Figure 1-2 In the figure, a represents the exterior wall, b represents the multi-layer exterior wall panel, c represents the hoisting rope, and d represents the steel column. The hoisting method of the three-story combined steel column sandwich insulation exterior wall panel of the prefabricated steel structure residence includes the following steps:

[0049] S1. First connect the hoisting rope to the inner end of the horizontally placed thermal insulation exterior wall panel and the steel columns at the upper and lower ends;

[0050] S2. Use the crane to control the hoisting rope to rise sequentially from right to left, thereby gradually lifting the thermal insulation exterior wall panel to make it in a vertical state;

[0051] S3. Install the thermal insulation exterior wall panel in the vertical state outside the wall through the steel column, and measure the verticality after installation;

[0052] S4. After measuring the verticality, tap and press the tilted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com