New energy battery mounting structure

An installation structure, new energy technology, applied in the direction of structural parts, secondary batteries, battery cover/end cover, etc., can solve the problems of reducing the use effect of the installation structure, trouble, affecting the stability of the battery, etc., to improve the cooling effect, improve the Safety and the effect of improving earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

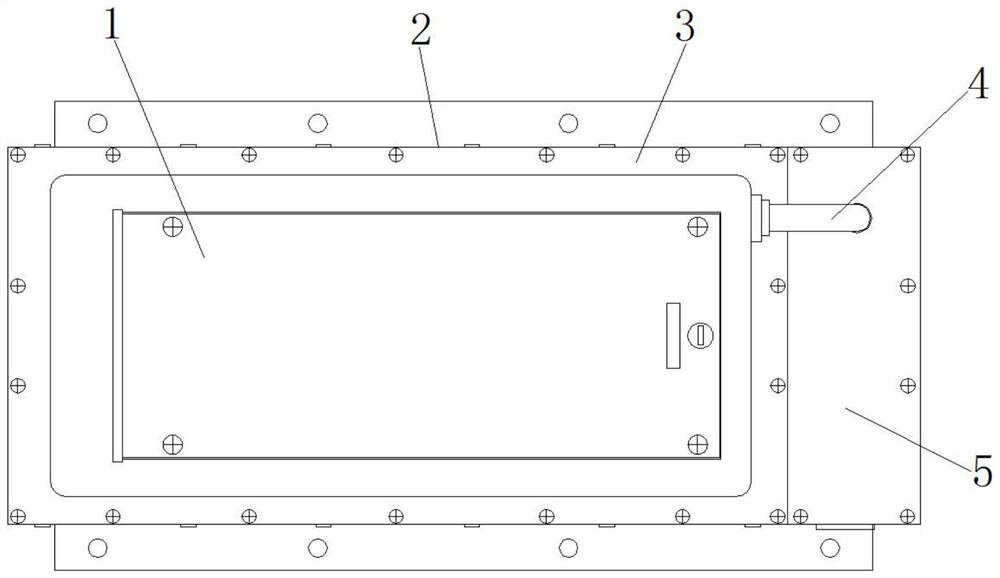

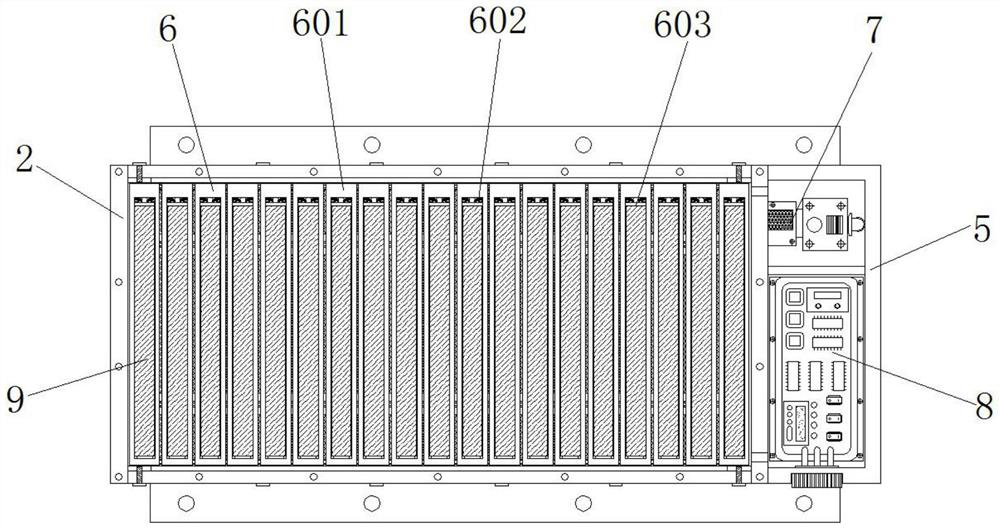

Embodiment 1

[0038] Example 1, such as Figure 1-7 As shown, when the new energy vehicle encounters a bumpy road during driving, the vibration is gradually transmitted to the battery installation structure, and the buffer spring 606 cooperates with the movable rod 604 to buffer the longitudinal stress on the battery board inside the card holder 601. The fixed spring 602 inside the installation hole 608 cooperates with the movable plate 603 to buffer the lateral stress on the battery board of the card seat 601. Through the two buffer structures, the shock resistance of the new energy battery installation structure can be greatly improved. When it is necessary to replace the damaged battery board inside the designated card holder 601, first open the installation cover 3, and then push the corresponding damaged battery board to the end of the card holder 601 close to the movable plate 603, so that the fixed spring 602 is shortened by force. At this time, the operator can directly take out the...

Embodiment 2

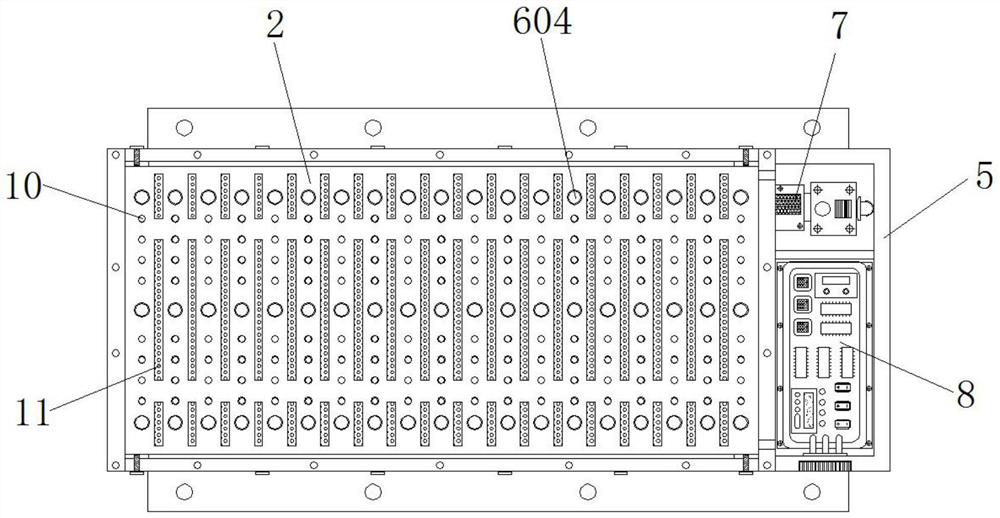

[0039] Example 2, such as Figure 1-7 As shown, when the battery board in the battery installation structure generates a large amount of heat due to work, the air pump 7 is first controlled by the external control panel to blow air into the interior of the installation compartment 17, and then cooperates with the energized semiconductor cooling chip 16 to blow the air into the installation compartment 17. The cold air inside 17 is blown into the inside of the jet chamber 15, and then the cold air is blown into between the multiple groups of battery panels inside the main body compartment 2 through the air outlet 11, and the multiple groups of battery panels are simultaneously cooled by wind, and the bottom of the battery panels generates The heat is transferred to the heat-conducting rod 10 through the heat-conducting plate 9, and the cold air will cool down the surface of the heat-conducting rod 10 in the process of passing through the interior of the air jet chamber 15, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com