Corrosion-resistant LED glass bulb with good air tightness and preparation method thereof

An air-tight and corrosion-resistant technology, applied in the field of LED glass bulb and its preparation, can solve problems such as cost and inconvenient use and maintenance, and achieve the effects of no toxic side effects, high physical strength, and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

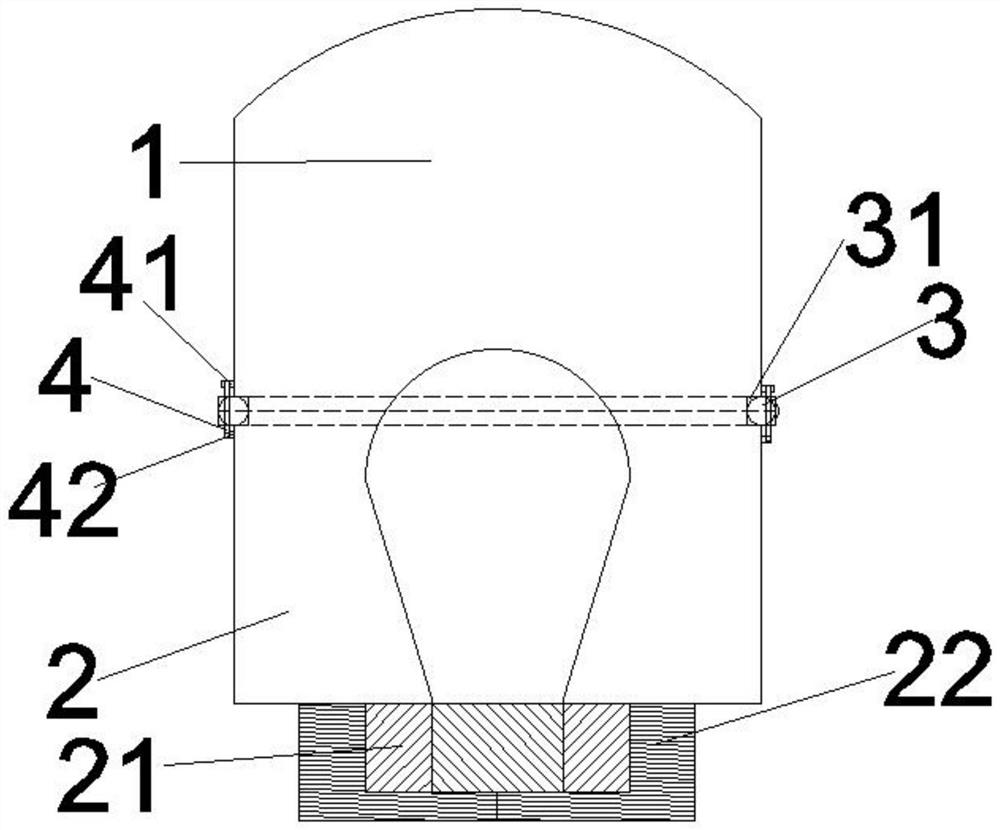

[0025] like figure 1 The shown corrosion-resistant and airtight LED glass bulb includes an upper housing 1, a lower housing 2, a light source socket 21, a sealing ring 3, a connecting groove 31, a fixing buckle 4, a fixing upper protrusion 41 and a fixing Lower protrusion 42. Wherein, the lower end of the upper shell 1 and the upper end of the lower shell 2 are covered. The connection groove 31 is provided at the cover joint of the upper casing 1 and the lower casing 2 . The sealing ring 3 is disposed in the connecting groove 31 and snapped into the connecting groove 31 . The upper fixing protrusion 41 is disposed on the upper casing 1 and is located at one end close to the connecting groove 31 . The lower fixing protrusion 42 is disposed on the lower casing 2 and is located at one end close to the connecting groove 31 . The fixing upper protrusion 41 and the lower fixing protrusion 42 are connected through the fixing buckle 4 . A light source socket 21 is integrally form...

Embodiment 2

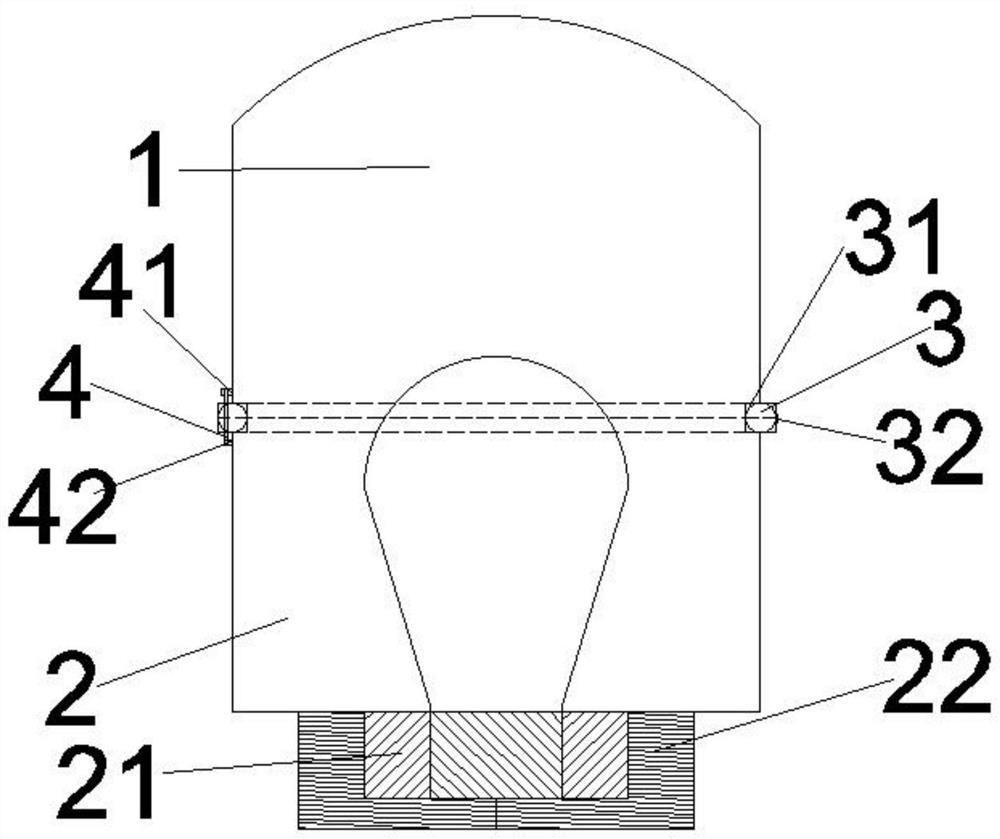

[0032] like figure 2 The shown corrosion-resistant and airtight LED glass bulb includes an upper housing 1, a lower housing 2, a light source socket 21, a sealing ring 3, a connecting groove 31, a fixing buckle 4, a fixing upper protrusion 41 and a fixing Lower protrusion 42. Wherein, the lower end of the upper shell 1 and the upper end of the lower shell 2 are covered. The connection groove 31 is provided at the cover joint of the upper casing 1 and the lower casing 2 . The sealing ring 3 is disposed in the connecting groove 31 and snapped into the connecting groove 31 . The upper fixing protrusion 41 is disposed on the upper casing 1 and is located at one end close to the connecting groove 31 . The lower fixing protrusion 42 is disposed on the lower casing 2 and is located at one end close to the connecting groove 31 . The fixing upper protrusion 41 and the lower fixing protrusion 42 are connected through the fixing buckle 4 . A light source socket 21 is integrally for...

Embodiment 3

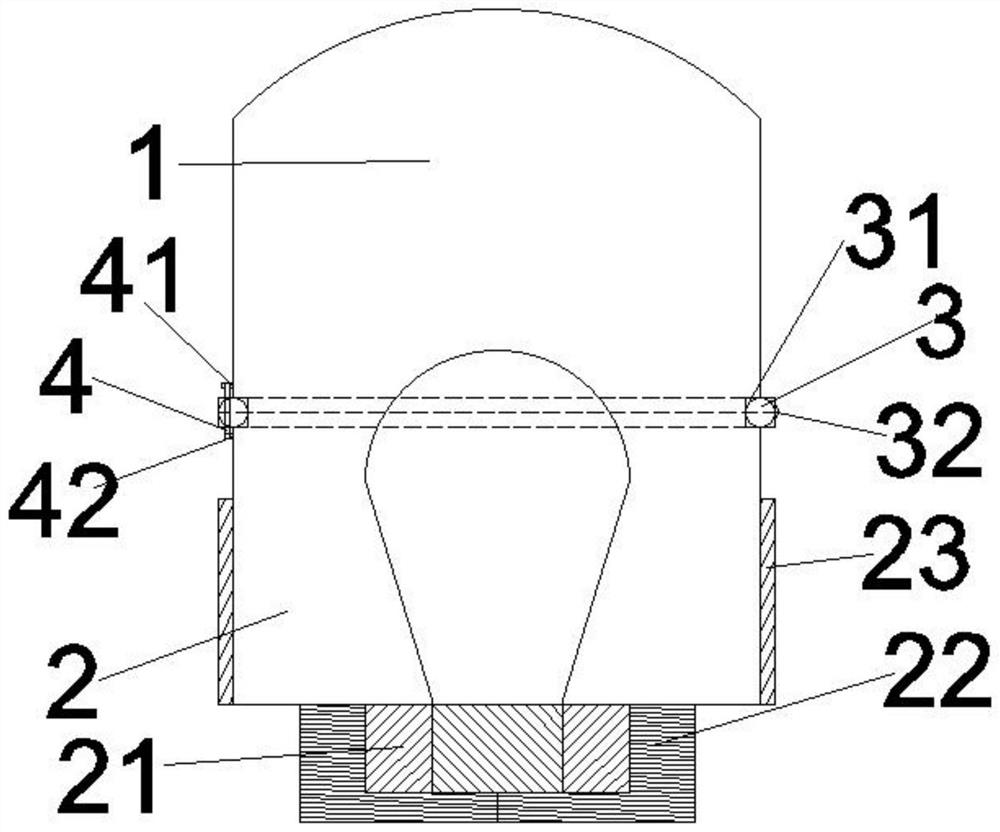

[0039] like image 3 The shown corrosion-resistant and airtight LED glass bulb includes an upper housing 1, a lower housing 2, a light source socket 21, a sealing ring 3, a connecting groove 31, a fixing buckle 4, a fixing upper protrusion 41 and a fixing Lower protrusion 42. Wherein, the lower end of the upper shell 1 and the upper end of the lower shell 2 are covered. The connection groove 31 is provided at the cover joint of the upper casing 1 and the lower casing 2 . The sealing ring 3 is disposed in the connecting groove 31 and snapped into the connecting groove 31 . The upper fixing protrusion 41 is disposed on the upper casing 1 and is located at one end close to the connecting groove 31 . The lower fixing protrusion 42 is disposed on the lower casing 2 and is located at one end close to the connecting groove 31 . The fixing upper protrusion 41 and the lower fixing protrusion 42 are connected through the fixing buckle 4 . A light source socket 21 is integrally form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com