Pressure sensor sealing pressure stabilizing structure

A technology of pressure sensor and voltage stabilization, which is applied in the direction of measuring fluid pressure, measuring fluid pressure through mechanical components, fluid pressure measurement of elastic deformation gauge, etc. It can solve the problems of affecting the measurement accuracy and the easy deformation of the isolation diaphragm, etc., to achieve The effect of preventing excessive cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

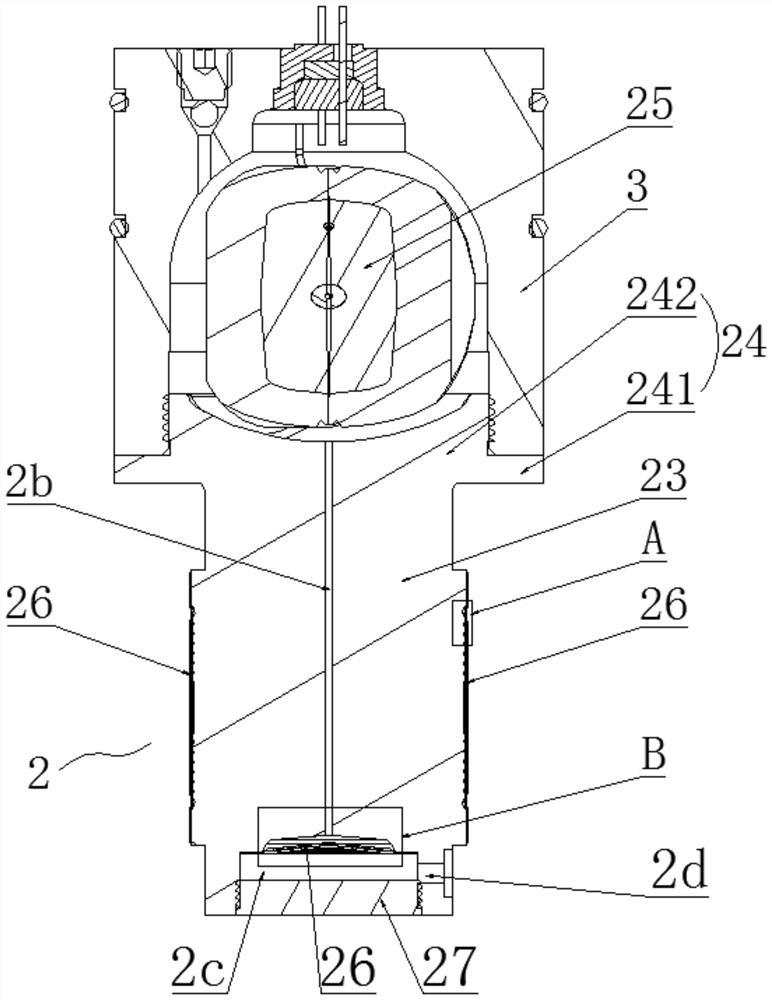

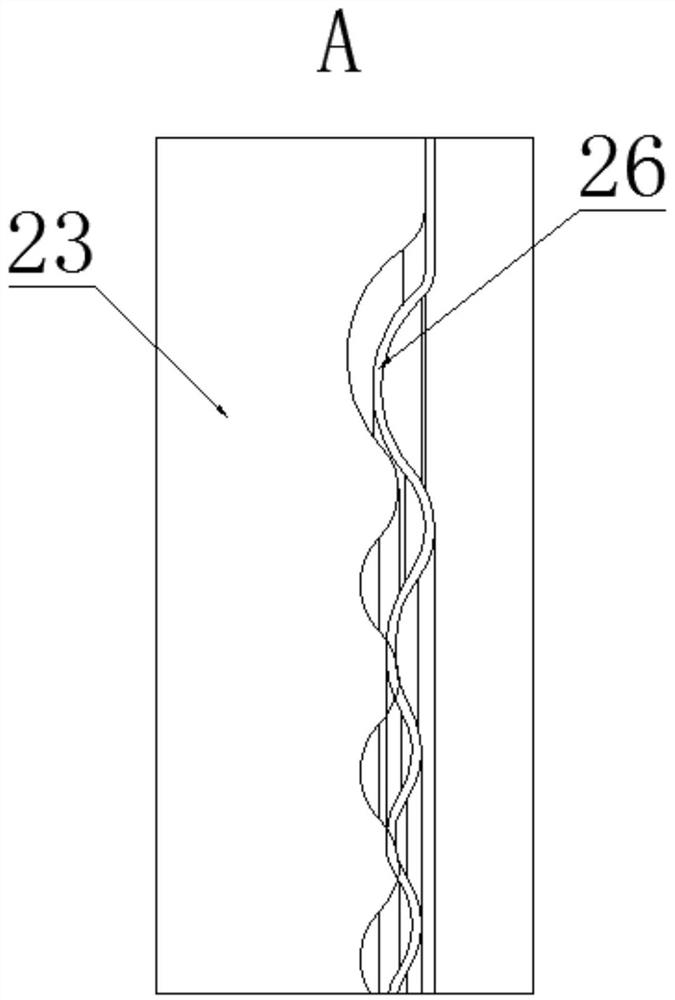

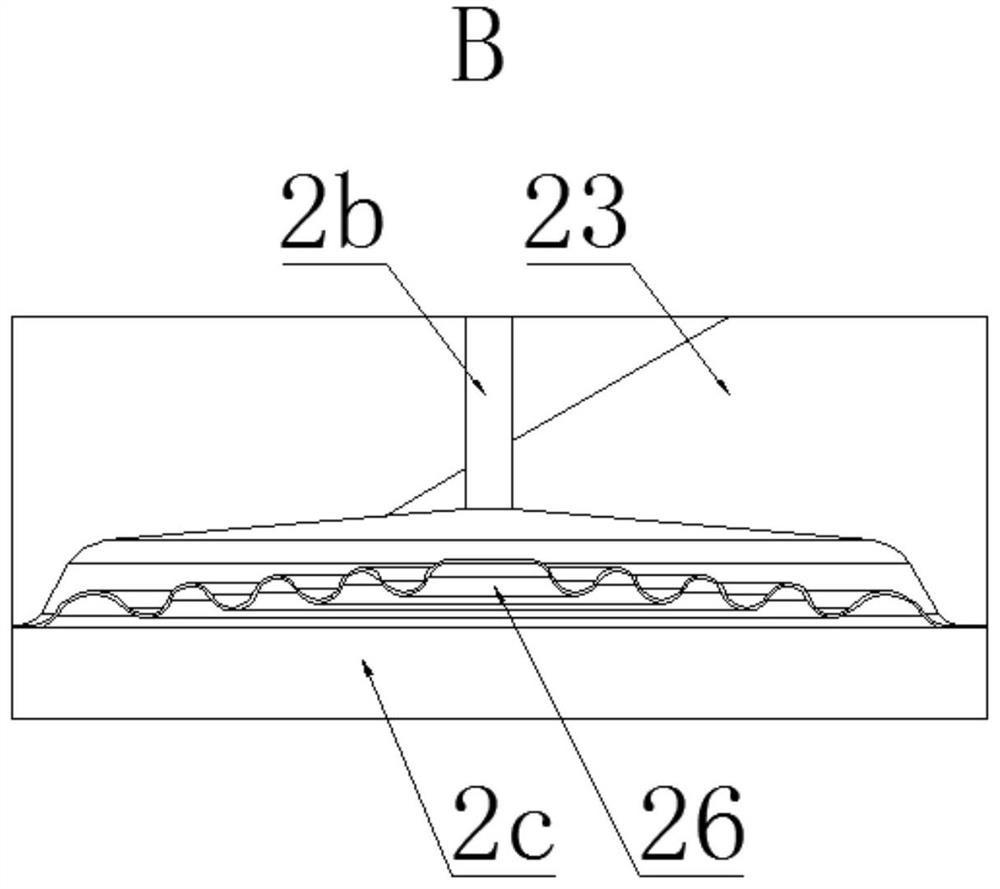

[0021] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

[0022] Such as Figure 1-8 As shown, a pressure sensor with a sealed and stable pressure structure includes a sealed installation cavity, a diaphragm pressure sensor 25 is arranged in the installation cavity, and two pressure introduction tubes 251 are drawn out from the diaphragm pressure sensor 25 , the inner ends of the two pressure introduction tubes 251 are connected to the inside of the diaphragm pressure sensor 25, and the outer ends of the two pressure introduction tubes 251 protrude from the installation cavity respectively. The cavity is filled with a pressure transmission medium, and the pressure transmission medium can be silicon oil.

[0023] To further improve the pressure balance effect, a pressure balance channel 2b is also connected to the installation cavity, the inner end of the pressure balance channel 2b is connected to the installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com