Shore durometer test force calibration device

A technology of Shore hardness tester and verification device, which can be used in measurement devices, strength characteristics, instruments, etc., and can solve the problems of error, complicated operation, and untraceable value of indication.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further described in conjunction with accompanying drawing and specific embodiment:

[0019] The main content of the present invention is to design a set of Shore hardness test force verification system, wherein the test force loading device can realize slow and steady loading of the test force, and keep the indication values of the Shore hardness tester and the standard force measuring instrument stable at the verification point.

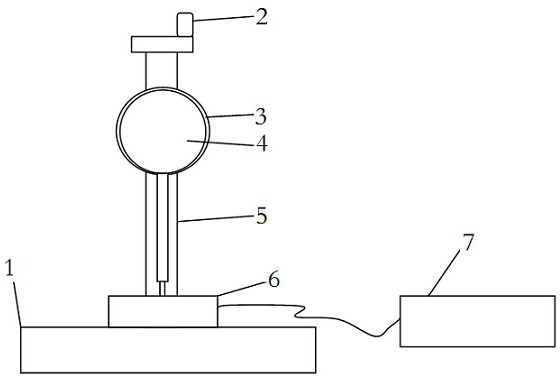

[0020] The present invention mainly designs a test force verification device for a Shore hardness tester. The device is composed of a special calibration stand, a force sensor, and a high-precision digital force tester.

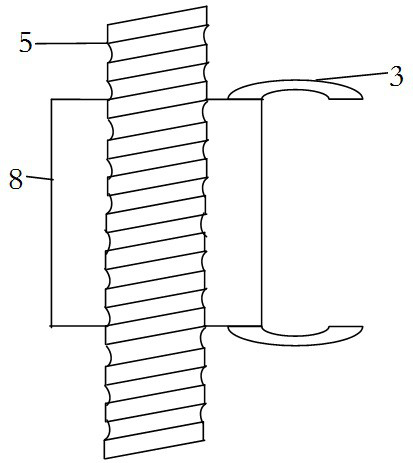

[0021] The calibration stand is mainly composed of a base and a screw nut transmission mechanism. Among them, a special clamp with a spring structure is designed on the nut mechanism, which can realize the fixing of Shore hardness testers of different sizes.

[0022] During verification, fix the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com